How does the electric power steering rack work in a car?

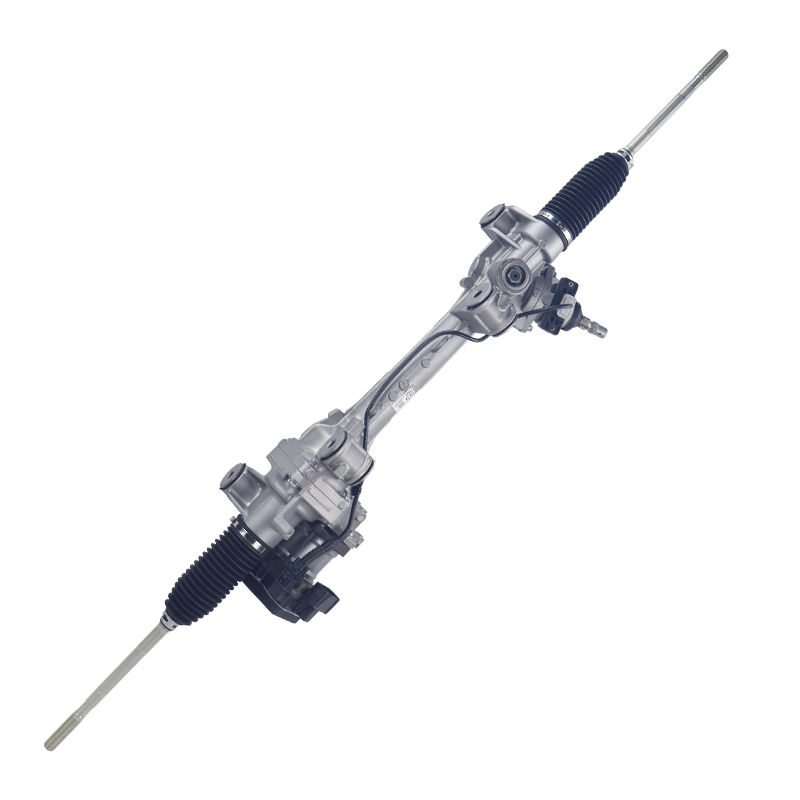

With the continuous development of automobile industry technology, the electric power steering (EPS) system has gradually become the mainstream technology in modern automobile steering systems in recent years. As one of the core components of this technology, the electric power steering rack (Electric Power Steering Rack, EPS rack) is being adopted by more and more automakers. This system can not only effectively reduce the driver's steering burden, but also improve the vehicle's handling, stability and fuel efficiency. In particular, as the requirements for automobile energy efficiency and driving experience continue to increase, the advantages of electric power steering racks are becoming more and more prominent.

So, how does the electric power steering rack work? How is it different from the traditional hydraulic power steering system? This article will discuss in detail the working principle, composition, function and application of the electric power steering rack in modern automobiles.

What is the electric power steering system?

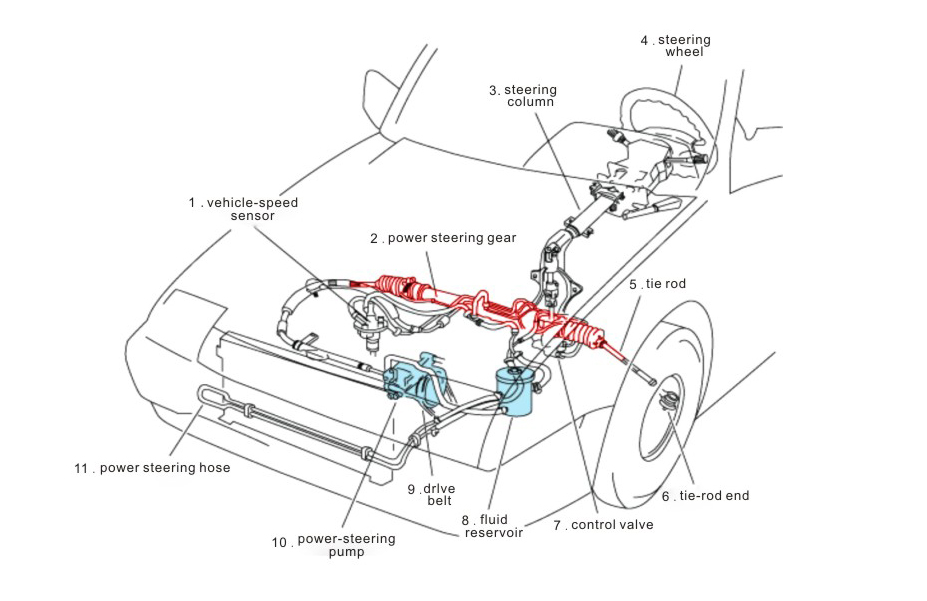

The electric power steering system (Electric Power Steering, EPS) is a technology that uses an electric motor instead of a traditional hydraulic pump to provide steering assistance. Compared with the traditional hydraulic power steering (HPS) system, the biggest feature of the EPS system is that it does not rely on the engine-driven hydraulic pump, but directly drives the vehicle's steering rack through an electric motor, reducing the vehicle's energy consumption while improving the system's response speed and accuracy.

The electric power steering rack is one of the core components of the electric power steering system. It is responsible for converting the rotational force provided by the motor into the steering operation of the steering wheel and transmitting this operation to the wheels. It is similar to the traditional mechanical rack, except that an electric power assist device is added to its internal structure.

What is the working principle of the electric power steering rack?

The working principle of the electric power steering rack can be divided into several key steps: sensor feedback, motor drive, and steering transmission. The following will introduce the working process of each link in detail.

1. The role of the steering force sensor

The work of the electric power steering system begins with the steering force sensor (Torque Sensor). When the driver turns the steering wheel, the sensor monitors the rotational torque on the steering wheel in real time. This information is transmitted to the vehicle's electronic control unit (ECU), and the ECU determines how much steering assistance is needed based on this information.

The sensor can not only sense the torque applied by the driver, but also identify the speed and direction of the steering. For example, when the driver turns the steering wheel, the system will analyze the driver's desired steering speed and the steering angle of the wheel through sensors. The system will adjust the amount of power provided according to different driving conditions (such as low speed or high speed), so as to achieve more flexible and precise control.

2. Driving function of the motor

According to the information fed back by the steering force sensor, the ECU sends instructions to the motor to instruct it to provide corresponding power. The motor is usually a DC motor or a stepper motor, which varies according to different models and needs. The role of the motor is to generate the torque required for steering and transmit it to the steering rack through the transmission system.

Compared with the traditional hydraulic power steering system, the motor of the electric power steering rack usually directly drives the steering rack. Because the rotation of the motor can achieve precise control, the system can accurately adjust the steering power according to the needs of the driver and provide different degrees of power under different driving conditions.

3. Transmission function of the steering rack

The motor transmits torque to the steering rack through a transmission mechanism (such as gears and nuts) to drive the wheels of the vehicle to steer. The steering rack consists of a rack and a pinion. The pinion is connected to the steering arm of the wheel through the rack to control the steering angle of the wheel. The movement of the rack directly affects the rotation of the wheel, and the motor adjusts the force of the steering rack to ensure that the driver can easily perform steering operations.

In the electric power steering rack, the connection between the rack and the motor is usually achieved through a small reduction gear system. This system can not only adjust the torque transmission ratio, but also improve the reliability and durability of the system. Through this transmission system, the torque generated by the motor can be effectively converted into the rotation of the wheel to help the driver complete the steering action.

4. Feedback and adjustment

A key feature of the electric power steering rack is its high feedback capability. When the vehicle is driving, the rotation of the steering wheel will be affected by factors such as vehicle speed and road conditions. The electric system can adjust the power assistance provided in real time. For example, when driving at low speed or parking, the system will increase the power assistance to reduce the heaviness of steering; while at high speed, the system will reduce the power assistance to improve the accuracy of control and the stability of the vehicle.

In addition, the electric power steering system can also be adjusted according to the dynamic performance of the vehicle. For example, during braking or turning, the system will adjust the steering force according to factors such as vehicle speed, turning angle, acceleration, etc., to ensure that the driver has a better control experience.

What are the structural components of the electric power steering rack?

The structure of the electric power steering rack is relatively complex and contains multiple key components to ensure that it can provide steering assistance efficiently and stably during operation.

1. Electric Motor

The electric motor is one of the core components of the electric power steering system and is responsible for providing the torque required for steering. It is usually installed in the center of the steering system and connected to the steering rack through a transmission mechanism. There are many types of electric motors, the most common of which include DC motors and stepper motors. The output torque of the motor can be controlled by current, and the system can adjust the power output of the motor according to the feedback signal of the sensor to achieve precise steering assistance.

2. Steering rack and pinion

The steering rack is an important component connected to the steering wheel, which is responsible for converting the rotation of the steering wheel into the steering of the wheels. The working principle of the electric power steering rack is similar to that of the traditional mechanical steering rack. Both transmit torque through the meshing of the rack and the gear, but the electric power steering rack adds an electric motor to provide power assistance.

3. Sensor and Control Unit (Sensor and ECU)

The steering force sensor and the electronic control unit (ECU) are the "brains" of the electric power steering system. The sensor monitors the steering force applied by the driver in real time and transmits the information to the ECU, which adjusts the power output of the motor based on this data. The ECU calculates the optimal steering assistance through a complex algorithm to ensure that the steering system can provide a precise control experience under different driving conditions.

4. Gearbox

The reducer or gearbox converts the high speed of the motor into a low speed and high torque suitable for transmission to the rack. Through the reducer, the output power of the motor is effectively converted, ensuring the smoothness and precision of the steering.

What are the advantages and disadvantages of the electric power steering rack?

1. Advantages of the electric power steering rack

● Energy saving and environmental protection: The electric power steering system is driven by an electric motor, avoiding the high energy consumption and pollution of the traditional hydraulic system. Compared with hydraulic systems, electric power steering systems can automatically adjust the size of the power assist as needed, reducing unnecessary energy waste.

● Precise control: The electric power steering system can adjust the power assist in real time and provide more precise steering response. This can bring a more relaxed and comfortable driving experience for the driver, especially when driving at high speeds and turning, the feedback and responsiveness of the system are particularly important.

● Reduce the burden on the vehicle body: The electric power steering system reduces the use of components such as hydraulic pumps, pipes, and oil, thereby reducing the total weight of the vehicle. Lightweight design helps improve fuel efficiency and reduce vehicle emissions.

● Highly integrated and flexible: The electric power steering system can be integrated with other electronic control systems (such as stability control systems, autonomous driving systems, etc.) to achieve more intelligent driving assistance functions.

2. Disadvantages of electric power steering racks

● Cost issues: The development and manufacturing costs of electric power steering systems are relatively high. Especially under the requirements of high-performance motors, sensors and control units, the manufacturing costs will increase further.

● Technical complexity: The electronic control and sensor technology involved in the electric power steering system is relatively complex, and the accuracy and stability of the system have high technical requirements. Any small fault or sensor failure may cause the steering system to malfunction, which in turn affects driving safety.

● Maintenance and repair: Although the maintenance requirements of the electric power steering system are relatively low, once a fault occurs, the repair may be complex and expensive. Especially when there is a problem with the motor or control unit, professional diagnosis and repair are required.

With a production capacity of 300,000 units annually, DKM is a trusted supplier of automotive power steering systems. Our advanced manufacturing facilities in Foshan, China, include over 280 CNC machines, ensuring precision and consistent quality. We provide steering solutions for brands like Hyundai, Honda, and Volkswagen, with competitive pricing for distributors and OEMs. DKM also offers wholesale deals, promotional discounts, and tailored solutions to meet specific market demands. Contact us today to request a detailed quote and explore our affordable, high-quality products.