How to solve the EPS failure of the car?

With the continuous advancement of automobile technology, more and more modern cars are equipped with electric power steering systems (EPS). Compared with traditional hydraulic power steering systems, EPS has higher efficiency, lower energy consumption and better response performance. However, like any complex mechanical and electronic system, EPS may also fail. When the EPS fault light comes on, many car owners may feel confused and uneasy.

So, how to solve the EPS failure of the car? Does this mean that there is a problem with the electric steering system? This article will explore this issue in detail and provide corresponding solutions.

What is the EPS system?

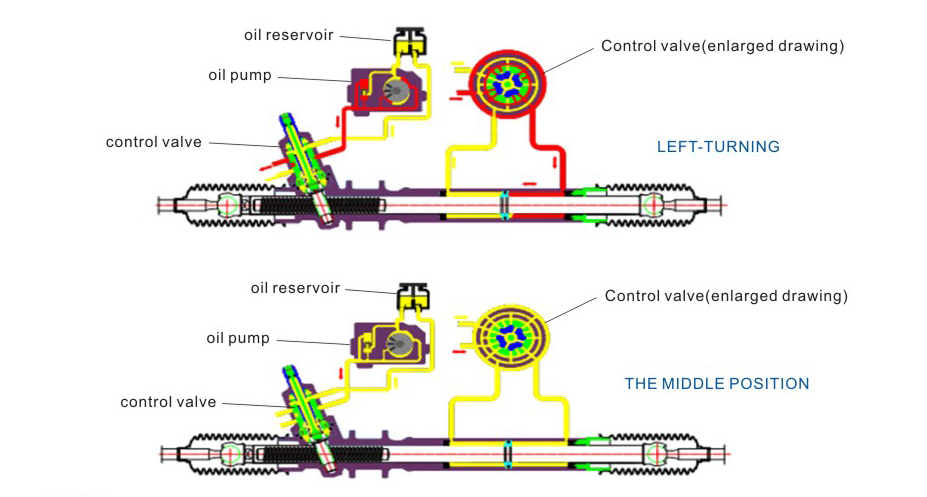

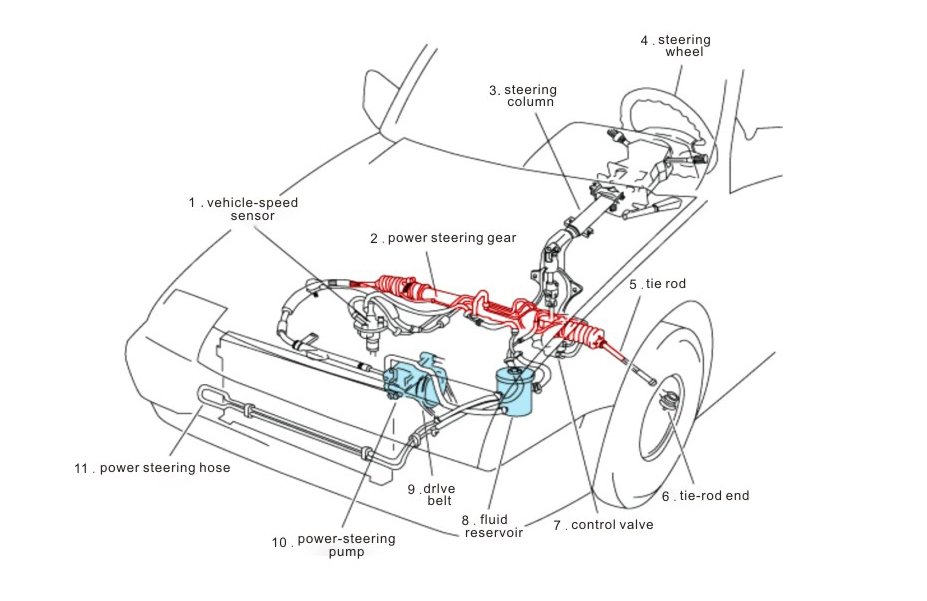

EPS, or Electric Power Steering, is a system that uses an electric motor to provide auxiliary steering force. Unlike traditional hydraulic power steering systems, EPS systems do not require hydraulic pumps, hydraulic oil and pipeline systems, but adjust the steering force through electric motors, sensors and electronic control units (ECU).

How does the electric power steering system work?

The core of the electric power steering system is an electric motor. When the driver turns the steering wheel, the sensor detects the steering angle and steering force and transmits this information to the electronic control unit (ECU). The ECU calculates the required steering assistance based on these data and controls the motor to provide the corresponding power, thereby reducing the driver's operating burden. This system can not only adjust the power assistance according to the vehicle speed, but also realize more intelligent functions, such as lane keeping assist.

What are the advantages of the electric power steering system?

● Energy saving and environmental protection: Since there is no continuous operation of the hydraulic pump, the EPS system basically does not consume electricity when the vehicle is driving straight, and only consumes electricity when steering is required.

● Precise control: Electronic control enables the electric power steering system to provide more precise steering assistance and improve the driving experience.

● Less maintenance requirements: Since the hydraulic system is cancelled, the electric power steering system reduces the occurrence of common problems such as oil leakage and oil pump failure, and the maintenance requirements are relatively low.

What are the common manifestations of electric power steering system failure?

Although the electric power steering system has many advantages over the hydraulic power steering system, it may still fail. Here are some common EPS failure manifestations:

The steering wheel becomes heavy

If the electric power steering system fails, the motor may not provide enough power assistance, causing the steering wheel to become heavy. In this case, the driver will feel that it is more difficult to turn the steering wheel than usual, especially when driving at low speed or parking.

Sudden loss of steering assistance

In some cases, the electric power steering system may suddenly lose power assistance, making steering extremely difficult. This situation is usually accompanied by the EPS warning light on the dashboard, alerting the driver that there is a problem with the system.

Steering wheel noise

The mechanical components and motors of the electric power steering system should usually be quiet when working. If the steering wheel makes unusual noises when turning, such as buzzing or grinding, it may indicate a mechanical or electronic failure in the electric power steering system.

Steering instability or hysteresis

If the sensor or ECU in the electric power steering system fails, it may cause steering instability or hysteresis. In this case, the vehicle's steering response may become less sensitive or delayed, affecting driving safety.

What are the possible causes of EPS failure?

The reasons for the failure of the electric power steering system are varied and may involve multiple aspects such as mechanical, electrical and electronic. Here are some common EPS failure causes:

Motor failure

The core component of the electric power steering system is the motor, which is responsible for providing steering assistance. If the motor fails, such as brush wear, motor bearing damage or winding burnout, it may cause the electric power steering system to not work properly, with insufficient or no power assistance.

Sensor failure

The electric power steering system relies on multiple sensors to sense information such as steering angle, steering force and vehicle speed. If these sensors fail, the ECU may receive incorrect data, causing the system to calculate incorrectly, which will affect the provision of steering assistance.

Electronic Control Unit (ECU) Failure

The ECU is the brain of the electric power steering system, responsible for processing sensor data and controlling the operation of the motor. If the ECU fails, such as software problems or hardware damage, it may cause the system to misjudge or not work properly.

Electrical connection problems

The electrical connections in the electric power steering system can also be the source of failure. If the wires are loose, the connectors are corroded or the fuses are blown, it may cause the system to lose power and fail to operate properly.

Low voltage problems

The electric power steering system relies on the vehicle's electrical system for power supply. If the vehicle battery voltage is too low, the electric power steering system may not provide enough power support, resulting in insufficient power assistance.

How to solve EPS failure?

When the owner encounters EPS failure, there is no need to panic. You can check and solve it by following the steps below:

Check the electrical system

First, check the vehicle's electrical system to make sure the battery voltage is normal. If the vehicle battery voltage is too low, you may need to charge or replace the battery. In addition, check the fuses and electrical connections of the electric power steering system to ensure that there is no looseness or corrosion.

Read the fault code

If the EPS warning light is on, it is recommended to use a car diagnostic instrument to read the fault code. The fault code can help determine the specific cause of the fault and guide the maintenance personnel to prescribe the right medicine.

Check the sensor and motor

After eliminating the electrical system problem, check the sensors and motors in the electric power steering system. Sensor failure may require recalibration or replacement, while motor failure may require replacement of the motor or its internal components.

Check the electronic control unit (ECU)

If you suspect that the ECU is faulty, you can try to reprogram or update the software and replace the ECU module if necessary. However, this usually requires professional maintenance equipment and technicians to operate.

Seek professional help

If the owner cannot solve the EPS failure by himself, it is recommended to go to a professional auto repair shop or 4S shop for help in time. Professional technicians can quickly diagnose and repair electric power steering system faults through professional equipment and technical means.

Precautions for EPS system

The EPS system has high requirements for the vehicle's electrical system, so the battery status and electrical connections should be checked regularly to ensure stable power supply. Secondly, avoid driving for a long time in extreme environments, such as high temperature, cold or high humidity environments, which may have an adverse effect on the electronic components and motors of the EPS system.

Once an abnormality is found in the EPS system, such as insufficient power assistance, warning lights on, or abnormal steering wheel noises, it should be handled in a timely manner to avoid further deterioration of the fault and affect driving safety.

With over 28 years of experience, DKM Company (Guangdong Diamond Auto Parts Co., Ltd.) specializes in manufacturing power steering systems for vehicles across Europe, the USA, and Asia. Our modern factory, located in Foshan, China, spans 20,000 square meters and features advanced CNC equipment. We produce gear-and-rack and hydraulic steering systems compatible with Toyota, Hyundai, Honda, and Mitsubishi models. Buyers can benefit from our competitive pricing, flexible customization options, and bulk discounts. Contact us today for a quote or to learn about ongoing promotions!