Hydraulic Steering System Vs. Electric Steering System: Which One Is More Expensive to Repair?

In car repair and maintenance, the cost of repairing the steering system is often one of the important issues that car owners are concerned about. Hydraulic steering system and electric steering system are the two most common steering power systems in the automotive market today. They each have their own advantages and disadvantages. When it comes to repair costs, which system costs more?

This article will conduct a comprehensive analysis from the perspectives of repair complexity, component costs, maintenance requirements, and repair cases to help car owners understand the difference in repair costs between the two systems.

How much does it cost to repair a hydraulic steering system?

1. Working principle and composition of hydraulic steering system

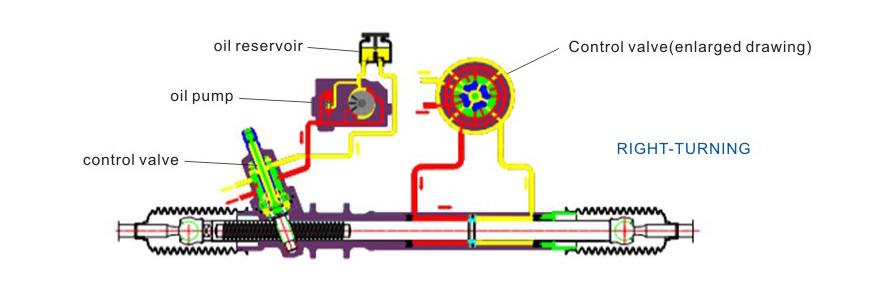

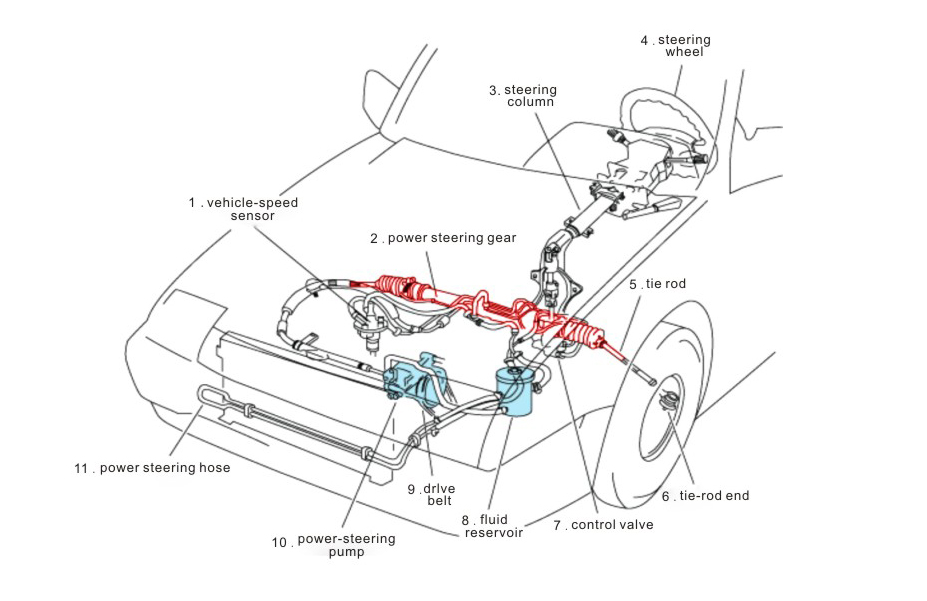

Hydraulic Power Steering (HPS) is a system that provides power to the steering system by pressurizing hydraulic oil through a hydraulic pump. This system consists of several key components, including hydraulic pumps, hydraulic cylinders, steering valves, hydraulic oil pipelines, and oil storage tanks. Because the system relies on mechanical and hydraulic components, its repair costs often involve multiple aspects.

2. Common repair items for hydraulic steering systems

● Hydraulic oil leakage: One of the most common faults in hydraulic steering systems is hydraulic oil leakage. Leaks can occur in pipes, seals, or joints. Repairing these leaks usually requires replacing seals, patching pipes, or replacing the entire hydraulic line. The cost of the repair depends mainly on the specific location of the leak and the parts that need to be replaced. Generally, seals are cheaper to replace, while the cost of replacing the entire hydraulic line is higher.

● Hydraulic pump failure: The hydraulic pump is the core component of the hydraulic steering system, and its failure may cause the system to completely lose power. Repair of the hydraulic pump usually involves replacing worn blades or bearings, and sometimes the entire pump may need to be replaced. Hydraulic pumps are expensive, and when combined with labor costs, the cost of repairs can increase significantly.

● Hydraulic cylinder repair: The pistons and seals in the hydraulic cylinder may wear out due to long-term use, causing hydraulic oil to leak or reduce power. Repairing a hydraulic cylinder usually requires disassembling the entire assembly and cleaning and replacing seals or pistons. This type of repair process is complicated and labor costs are high.

● Steering valve failure: The steering valve is responsible for regulating the flow and pressure of the hydraulic oil. If the steering valve is stuck or fails, repairs usually require disassembling and cleaning the valve body, or replacing damaged parts. Due to the precision structure of the steering valve, the repair cost may be high.

3. Complexity and cost of repairing hydraulic steering systems

The repair cost of hydraulic steering systems is usually high because the system relies on a variety of mechanical and hydraulic components, which are not only expensive but also complex to repair. Although the cost of repairing hydraulic oil leaks is relatively low, if it involves repairing hydraulic pumps, hydraulic cylinders or steering valves, the cost may increase significantly. In addition, hydraulic steering systems require regular replacement of hydraulic oil, which is also a cost that car owners need to consider in long-term use.

How much does it cost to repair an electric steering system?

1. Working principle and composition of electric steering systems

The electric power steering system (EPS) relies on the motor to provide power assistance. It detects the steering wheel rotation angle and force through sensors and transmits signals to the control unit (ECU). The ECU controls the rotation direction and force of the motor to achieve wheel steering. Since the hydraulic system is no longer required, the structure of EPS is relatively simple, mainly consisting of motors, sensors, ECUs and mechanical connection components.

2. Common maintenance items of electric steering systems

● Sensor failure: The electric steering system relies on multiple sensors to detect the steering wheel rotation angle and force. Sensor failure may cause the system to fail to provide accurate power assistance. The cost of replacing a sensor is usually not high, but if it involves complex sensor calibration or wiring repairs, the cost may increase.

● Motor failure: The motor is the core component of the EPS system, and its failure may result in reduced or complete loss of power assistance. The cost of replacing the motor is high, especially the motor used in high-performance models, which is more expensive. In addition, the repair of the motor usually requires professional equipment and technology, which further increases the cost of repair.

● Control unit (ECU) failure: The ECU is responsible for processing sensor signals and controlling the operation of the motor. ECU failure may cause system failure or insufficient power assistance. The cost of replacing or repairing the ECU is high, especially if the system needs to be reprogrammed or calibrated, which will increase the cost further.

● Power supply problems: The EPS system relies on the vehicle's electrical system, so problems with the battery or generator may also affect the steering power. Although the repair cost of power supply problems is usually low, if it involves replacing the generator or other electrical components, the cost may increase.

Repair complexity and cost of electric steering systems

Compared with hydraulic steering systems, the repair cost of electric steering systems may be higher in some aspects, especially when it comes to repairing the motor or ECU. This is because the parts of electric steering systems are more expensive and the system is highly dependent on electronic components, which usually require professional equipment and technical support to repair. In addition, faults in electric steering systems usually need to be determined by electronic diagnostic tools, which also increases maintenance costs.

However, the structure of electric steering systems is relatively simple, without complex mechanical parts such as hydraulic oil, hydraulic pumps and hydraulic pipes, so their overall maintenance costs may be lower, especially when frequent hydraulic oil changes are not required during long-term use.

Hydraulic steering system vs. electric steering system: Whose repair cost is more expensive?

Parts cost

● Hydraulic steering system: The parts cost of hydraulic steering systems is mainly concentrated in hydraulic pumps, hydraulic cylinders, steering valves and hydraulic oil pipes. These parts are expensive, especially when replacing hydraulic pumps or hydraulic cylinders, the cost may increase significantly.

● Electric steering system: The parts cost of electric steering systems is mainly concentrated in motors, sensors and ECUs. Although these parts are expensive, since the system does not require hydraulic oil and related mechanical parts, the overall parts cost may be lower in some cases.

Repair complexity and labor costs

● Hydraulic steering system: The repair complexity of hydraulic steering systems is higher, especially when it comes to hydraulic oil leakage, hydraulic pumps or hydraulic cylinder repairs. The repair process usually requires disassembly of multiple parts and precise sealing and assembly work. Therefore, the labor cost of hydraulic steering systems is usually higher.

● Electric steering system: The repair complexity of electric steering system is relatively low, but because the system relies on electronic components, repairs usually require professional equipment and technical support, especially when it comes to repairing the motor or ECU. Although the repair process may be relatively simple, the price of electronic components and the use of professional diagnostic tools increase the cost of repair.

Maintenance requirements and long-term costs

● Hydraulic steering system: Hydraulic steering system requires regular replacement of hydraulic oil and inspection and maintenance of related components. These maintenance requirements increase costs in long-term use, especially after the system ages, leakage and wear problems are more common.

● Electric steering system: The maintenance requirements of electric steering system are relatively low. Since there is no hydraulic oil and related mechanical parts, car owners do not need to worry about hydraulic oil leakage or replacement. However, if the system fails, the repair cost may be high, especially after the system is out of warranty.

Summary: Whose repair cost is more expensive?

In summary, the repair costs of hydraulic steering system and electric steering system are different. The repair cost of hydraulic steering system is generally higher, especially when it comes to repairing hydraulic pumps, hydraulic cylinders or steering valves. Because hydraulic systems rely on multiple mechanical and hydraulic components, the cost of repairing and replacing these components can increase significantly. In addition, hydraulic steering systems require regular maintenance, which also increases costs in long-term use.