Is electric rack and pinion the best steering device?

In the development of modern automobile technology, the steering system has evolved from traditional mechanical steering to hydraulic power steering and then to today's electric power steering system. The core function of the steering device is to convert the driver's control into the movement of the wheel, and electric rack and pinion, as an important form of electric power steering system, has been widely used in recent years.

Compared with the traditional hydraulic power steering system, the electric rack and pinion system (ERPS) has attracted the attention of a large number of car companies due to its simple structure, high energy efficiency and fast response.

However, can it be said that electric rack and pinion is the best steering device? In order to answer this question, we need to analyze the characteristics, advantages and disadvantages of electric rack and pinion and its comparison with other steering devices from multiple angles.

What are the components of electric rack and pinion?

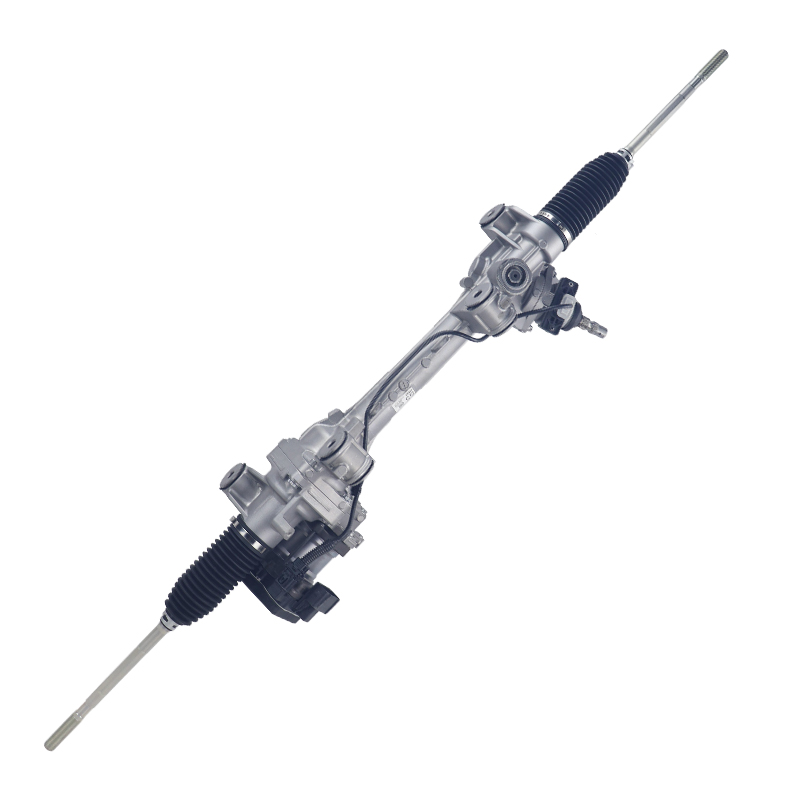

The electric rack and pinion steering system is a steering device based on electric power steering. Its basic components include rack, pinion, servo motor, sensor, control unit and battery.

● Rack and pinion: This part is similar to the traditional mechanical steering system. The rack is a long strip with teeth that meshes with the pinion. The pinion drives the linear motion of the rack by rotating, thereby turning the wheel. The combination of the rack and the pinion is still the core component of the steering system.

● Servo motor: In the electric power steering system, the servo motor replaces the traditional hydraulic pump. It is responsible for providing the power required for steering, and the motor adjusts the steering power through current control. This makes the output of the steering system more precise and responsive.

● Sensors and control units: In order to make the steering system more intelligent, the electric rack and pinion system integrates a large number of sensors, such as torque sensors and vehicle speed sensors. These sensors monitor the driver's steering input and road conditions in real time and transmit data to the control unit. The control unit adjusts the output of the motor based on data feedback to achieve steering assistance adapted to different driving conditions.

● Battery: The battery in the electric rack and pinion system provides power for the servo motor and control unit to ensure the continuous operation of the system.

What are the advantages of electric rack and pinion?

As a steering device, electric rack and pinion has many advantages, especially in modern vehicles, it can provide a more flexible, precise and efficient steering experience. Its main advantages include the following:

Energy saving and high efficiency

Compared with hydraulic power steering systems, electric rack and pinion systems do not rely on the engine to drive the hydraulic pump, but are powered by electric motors. This greatly improves the energy efficiency of the system, and can intelligently adjust the power output as needed when the vehicle is running, avoiding energy waste in the hydraulic system. In low-power demand situations such as when the car is parked or driving at low speeds, the electric steering system can significantly reduce energy consumption.

Responsiveness and precision

The electric rack and pinion system provides more precise steering control. Due to the power output of the motor and the real-time feedback of the control system, the driver can get a more sensitive steering response. Especially at high speeds or complex road conditions, the electric rack and pinion can provide a smoother and more predictable steering feel, improving driving comfort and safety.

Reduced system complexity and maintenance costs

Traditional hydraulic power steering systems require the use of hydraulic oil and components such as pumps, oil pipes, and filters, which not only increase the complexity of the system, but also require regular inspection and replacement. In contrast, the electric rack and pinion system has a simpler structure, reduces the use and wear of mechanical parts, and greatly reduces maintenance costs.

More flexible adjustment and adaptability

The electric rack and pinion system can adjust the steering assist according to different driving needs. For example, when driving at high speed, the system will automatically reduce the assist to make the steering more stable, while at low speed or parking, the system will increase the assist to make the steering wheel operation easier. This intelligent adjustment method can make real-time adjustments according to the driver's needs and road conditions, providing a more personalized driving experience.

Can be integrated with other systems

Another significant advantage of the electric rack and pinion system is that it can be seamlessly integrated with other intelligent driving assistance systems (such as automatic driving systems, lane keeping assist systems, collision warning systems, etc.). By coordinating with these systems, the electric steering system can not only provide the power required by the driver, but also cooperate with the intelligent control of the vehicle to further improve the safety and convenience of the vehicle.

What are the disadvantages of electric rack and pinion?

Although the electric rack and pinion system has many advantages, it also has certain disadvantages, which are mainly reflected in the following aspects:

High cost

The production cost of the electric rack and pinion system is high. Because it involves high-precision components such as motors, control units, sensors and batteries, the complexity of manufacturing and assembly increases the overall cost of the vehicle. Therefore, vehicles equipped with electric rack and pinion are often more expensive than those with traditional hydraulic steering systems.

Battery dependence

The core components of the electric rack and pinion system are the electric motor and battery, which makes the operation of the system completely dependent on the power supply of the battery. If there is a problem with the battery or the battery is insufficient, the steering power will not work properly, and in severe cases, it may even cause the vehicle to lose its steering function. Therefore, the performance and life of the battery are a challenge faced by the electric steering system.

Performance issues in high or low temperature environments

The electric rack and pinion system may be affected by extreme temperature conditions. For example, in extremely cold environments, the battery's operating efficiency may decrease, causing the electric steering system to respond more slowly or fail; in high temperature environments, overheating of the motor and battery may also cause unstable system performance. Therefore, how to ensure the stability of the system in different temperature environments is a problem that the electric rack and pinion system needs to solve.

System complexity

Although the electric rack and pinion system is simpler in structure than the traditional hydraulic system, it relies on the support of the electronic control and sensor system. Such a complex system may face problems such as electronic component failure and electrical system failure, which in turn affects the steering performance. Compared with traditional mechanical or hydraulic systems, electric systems require higher technical requirements and more frequent inspection and maintenance.

Differences in driving experience

Although the electric rack and pinion system can provide precise steering control, it is different from the traditional hydraulic system in the sensory experience of some drivers. Especially in terms of control feel and feedback strength, some drivers may prefer the stability and strength brought by the hydraulic system, and the feedback of the electric system may appear too light and lack sufficient road feedback. This may become a challenge for electric steering systems, especially for users who drive high-performance vehicles or pursue a more direct control feel.

Comparison of electric rack and pinion with other steering systems

The electric rack and pinion system has obvious advantages over traditional hydraulic steering systems and mechanical steering systems, but there are also some unavoidable shortcomings. The following comparison with other steering systems will help us more comprehensively evaluate the advantages and disadvantages of the electric rack and pinion system.

Comparison with hydraulic power steering system

The hydraulic power steering system provides power to the steering system through a hydraulic pump, which is common in traditional cars. The hydraulic system has efficient steering power performance, especially when driving at high speeds, the hydraulic steering system can provide sufficient power. However, hydraulic systems require more complex hydraulic oil pipelines, oil pumps, oil cylinders and other accessories, and oil leakage and maintenance costs are high. The electric rack and pinion system is usually more efficient than the hydraulic system, can provide more precise control, and avoid the waste and leakage of hydraulic oil.

Comparison with mechanical steering system

The mechanical steering system achieves steering through pure mechanical connection, and the earliest vehicles basically use mechanical steering. Mechanical steering has a simple structure and extremely high reliability, but because there is no power-assist system, the steering operation is more laborious. In modern cars, mechanical steering is almost only used in some specific models, such as racing cars or some economy cars. The electric rack and pinion system provides greater power assistance, making driving easier, while retaining a certain sense of mechanical feedback, making the driving experience more intelligent and comfortable.

Is the electric rack and pinion the best steering device?

In summary, the electric rack and pinion system has obvious advantages in many aspects, including energy saving and high efficiency, intelligent control, good responsiveness and low maintenance cost. But at the same time, it also has certain defects in cost, battery dependence, extreme environmental adaptability and control feel.

Guangdong Diamond Auto Parts Co., Ltd. is a trusted name in the automotive steering industry, offering wholesale and customized steering solutions since 1996. Our factory, with over 280 advanced machines, supports a production capacity of 300,000 units annually, serving vehicle brands such as Toyota, Honda, Volkswagen, and Hyundai. Exporting to the USA, Europe, and Southeast Asia, we provide high-quality products at low prices, ensuring excellent value for distributors and OEM buyers. Contact us today for factory quotes, bulk purchasing options, and exclusive promotions.