What kind of power steering rack does a new energy electric vehicle use?

Today, as new energy vehicles (electric vehicles) are gradually becoming mainstream, their core components and technical configurations are also receiving more and more attention. Among them, the power steering system, as an important component of vehicle driving safety and driving experience, has a decisive impact on the performance and comfort of electric vehicles. Different from traditional fuel vehicles, new energy electric vehicles have significant differences in their power systems, which also puts forward new requirements for the design and selection of their power steering racks.

This article will discuss in detail the type of power steering rack used in new energy electric vehicles and its working principle to help readers better understand this key technology.

What is a power steering rack?

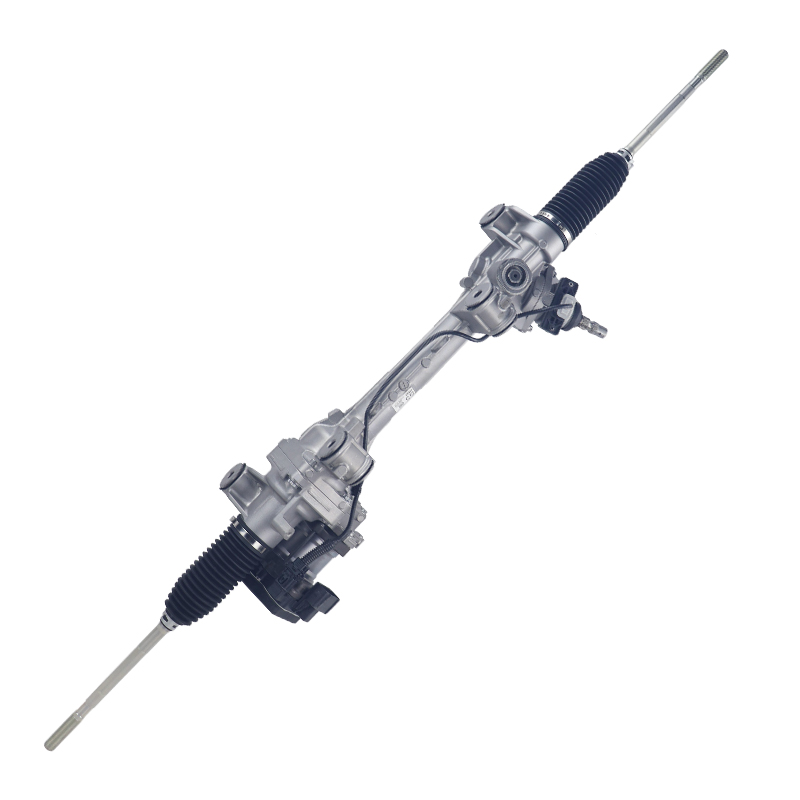

The power steering rack (Power Steering Rack) is the core component of the automobile steering system. Its main function is to reduce the force required by the driver when turning the steering wheel through an auxiliary device, thereby achieving easy control of the vehicle. Traditional fuel vehicles mostly use hydraulic power steering systems, but with the popularity of electric vehicles, electric power steering systems (EPS) have gradually become mainstream.

What are the types of traditional power steering racks?

Before introducing the power steering rack of electric vehicles, it is necessary to review the common types of power steering racks in traditional fuel vehicles. This helps to understand the technology choices for electric vehicle power steering systems.

Hydraulic Power Steering Rack

Hydraulic power steering provides steering assistance via a hydraulic pump. When the driver turns the steering wheel, the hydraulic oil is pressurized and acts on the steering rack through the pipeline, thereby reducing the driver's operating force. This system relies on the engine to provide power, so the hydraulic assist function does not work properly when the engine is turned off.

Electric Power Steering Rack (EPS)

Electric power steering does not rely on hydraulic pressure, but instead provides assistance through an electric motor. The electric motor is directly connected to the steering rack or steering column and provides appropriate power assistance to the driver based on the steering wheel rotation angle and torque signals detected by the sensor. Since the electric power assist system does not require a hydraulic pump and related pipelines, its structure is simpler, and the power assist can be adjusted according to vehicle speed, providing a more flexible steering experience.

What kind of power steering rack does a new energy electric vehicle use?

New energy vehicles, especially pure electric vehicles, usually choose electric power steering systems when designing their power steering systems. The main reasons are as follows:

Energy matching of electric power steering systems

The electric power steering system is driven by an electric motor, which is highly consistent with the overall energy structure of electric vehicles. The electric vehicle itself relies on batteries to provide energy, and the electric power-assist system is also powered by batteries, which simplifies energy management and avoids additional energy conversion losses. At the same time, the electric power assist system can still work normally without an engine, which is in line with the design characteristics of electric vehicles.

Efficient energy use

The hydraulic power steering system relies on the engine to drive the hydraulic pump, so when the engine is working, the hydraulic system is always consuming energy, even if the vehicle is traveling straight. However, the electric power steering system only provides assistance when needed. When the vehicle is traveling straight, the electric motor is in standby mode and does not consume additional energy. This on-demand energy supply feature makes the electric power-assist system more efficient and meets the high requirements for energy utilization efficiency of new energy vehicles.

Simple structure and high reliability

The structure of the electric power steering system is simpler than that of the hydraulic system, eliminating the need for complex components such as hydraulic pumps, oil pipes, and valves, reducing failure points. In addition, the electric system does not require regular replacement of hydraulic oil or maintenance of the hydraulic system, reducing maintenance costs and ease of use. For electric vehicles seeking high reliability and low maintenance, electric power assist systems are ideal.

How does an electric power steering rack work?

The electric power steering system (EPS) mainly consists of the following parts: steering wheel, steering column, sensors, control unit, electric motor and steering rack.

Sensors and Signal Acquisition

When the driver turns the steering wheel, a sensor located on the steering column detects the steering angle and the applied torque in real time. This data is transmitted to the control unit as an input signal for power steering.

Calculation and command output of the control unit

The control unit (ECU) calculates the required amount and direction of power assistance based on the data collected by the sensor and other information such as vehicle speed and steering angle. Subsequently, the control unit issues corresponding instructions to the motor to adjust the output of the motor.

Electric motor driven steering rack

After receiving instructions from the control unit, the electric motor drives the steering rack according to the set parameters and transmits power to the wheels through the gear transmission system, making the vehicle steering easier and more accurate. Unlike the hydraulic system, the electric motor responds faster and the power output is more precise.

What are the advantages of an electric power steering rack?

Since the electric power assist system relies on the electronic control unit (ECU) for adjustment, its power assist output can be flexibly adjusted according to a variety of parameters to provide a more precise steering experience. For example, the system can adjust the amount of power assistance based on vehicle speed: providing more power at low speeds and reducing power at high speeds to improve stability.

The electric power steering system is designed with energy efficiency in mind. Since electric energy is only consumed when turning, the EPS system reduces unnecessary energy loss compared to the hydraulic power assist system, which is particularly important for improving the cruising range of new energy vehicles.

The electric power assist system has no consumable parts such as hydraulic oil and has a simple structure, which greatly reduces the failure rate and maintenance requirements. For new energy trams that rely on electric motors and electronic systems, such a design is more in line with the overall maintenance strategy.

The power-assisted characteristics of the electric power steering system can be adjusted through software to meet different driving conditions and user needs. This programmable feature allows automakers to provide personalized steering feel for different models, or even different versions of the same model, to enhance the user experience.

Summarize

In the field of new energy vehicles, electric power steering (EPS) has become a mainstream choice. Due to its many advantages such as high efficiency, precision, simple structure and easy maintenance, the electric power assist system has almost completely replaced the traditional hydraulic power assist system. Through the electric power steering system, new energy electric vehicles can not only achieve easy steering operations, but also reach new heights in terms of energy conservation, environmental protection and driving experience.