Why is my hydraulic steering rack not working? What went wrong?

The hydraulic steering rack is one of the most important components in modern cars. It uses hydraulic power to enable the driver to easily control the steering wheel and thus control the direction of the vehicle. However, in daily use, the hydraulic steering rack sometimes fails, causing the steering system to be insensitive or completely ineffective.

For car owners, it is important to understand the reasons why the hydraulic steering rack may fail and how to solve these problems.

How does the hydraulic steering rack work?

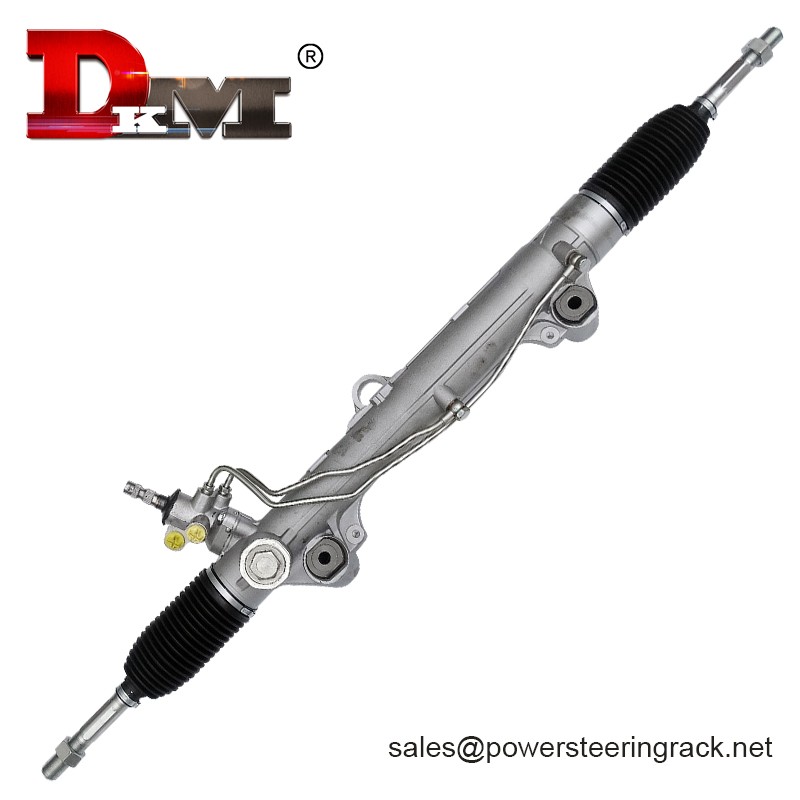

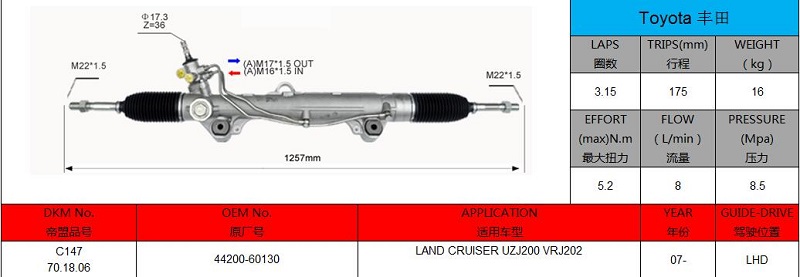

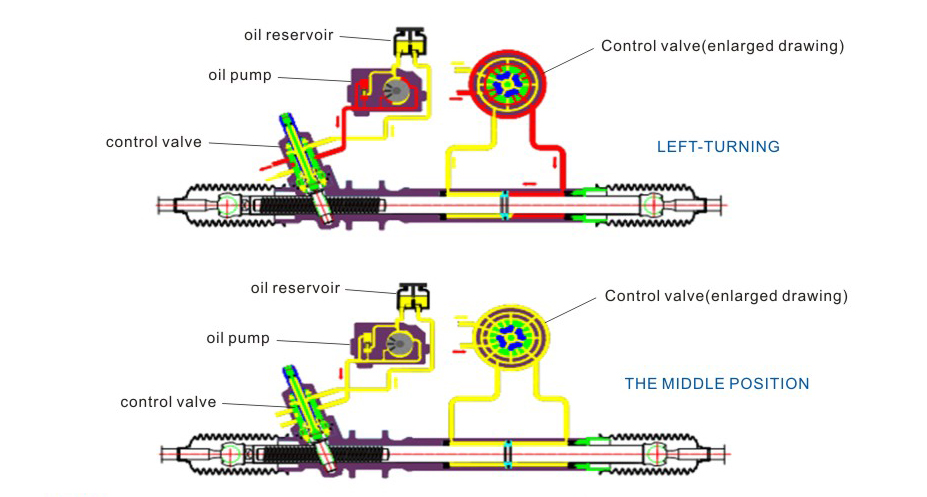

Before exploring the reasons why the hydraulic steering rack fails, it is necessary to understand its basic working principle. The hydraulic steering system generates hydraulic pressure through the engine-driven hydraulic pump, and the pressure is delivered to the hydraulic cylinder in the steering rack through the steering oil pipeline. When the driver turns the steering wheel, the steering valve connected to the steering shaft controls the flow of hydraulic oil, which in turn pushes the steering rack to move left and right, driving the wheels to turn.

Why is my hydraulic steering rack not working?

There may be a variety of reasons why the hydraulic steering rack is not working. These reasons involve multiple components of the system, from the hydraulic pump, the oil pipe, to the hydraulic oil itself, which can be the source of the problem. The following are several major factors that lead to failure of hydraulic steering racks:

1. Hydraulic oil leakage

● Phenomenon: The steering wheel becomes heavier and the steering is sluggish.

● Cause: Hydraulic oil leakage is one of the most common problems in hydraulic steering systems. Leakage may occur in the steering oil pipe, joints, seals and hydraulic cylinders. When the hydraulic oil leaks, the system pressure is insufficient, causing the hydraulic power to weaken or disappear.

● Solution: Check and repair the oil leak, replace the damaged oil pipe or seal, and replenish or replace the hydraulic oil.

2. Hydraulic pump failure

● Phenomenon: Steering has no power assistance and the engine noise increases.

● Cause: The hydraulic pump is the core component of the hydraulic steering system and is responsible for generating hydraulic pressure. If the hydraulic pump is damaged or the internal parts are severely worn, the hydraulic oil will not be delivered to the steering rack normally, and eventually the steering system will fail.

● Solution: Check the working status of the hydraulic pump. If abnormal noise or insufficient pressure is found, the hydraulic pump should be replaced in time.

3. Insufficient or deteriorated steering oil

● Phenomenon: The steering system operates unstably, and the steering wheel vibrates or makes abnormal noises.

● Cause: The hydraulic steering system relies on the lubrication and pressure transmission of hydraulic oil. If the amount of hydraulic oil is insufficient, the system cannot provide sufficient pressure; if the hydraulic oil deteriorates or is contaminated, it may cause the steering rack and valve to become stuck or worn.

● Solution: Check the hydraulic oil level regularly and replenish or replace the hydraulic oil when necessary. Make sure to use hydraulic oil that meets the specifications and avoid mixing impurities.

4. Steering valve failure

● Phenomenon: Steering wheel failure or stagnation, inaccurate steering.

● Cause: The steering valve is responsible for controlling the flow of hydraulic oil. The valves, springs and seals inside it may wear or get stuck after long-term use. If the steering valve does not work properly, the hydraulic oil cannot flow accurately to the steering rack, resulting in steering failure.

● Solution: Check the operation of the steering valve. If wear or sticking is found, it should be repaired or replaced in time.

5. Internal wear of the steering rack

● Phenomenon: Abnormal noise is heard when steering, and the steering wheel is difficult to return to the center.

● Cause: The gears and sliding parts inside the hydraulic steering rack may wear after long-term use. If the gear and rack are not well matched, or the sliding parts are severely worn, the hydraulic power will be greatly weakened or even completely fail.

● Solution: Disassemble and check the inside of the steering rack. If worn parts are found, they should be repaired or replaced.

6. Steering system air resistance

● Phenomenon: Steering wheel shakes and steering is not smooth.

● Cause: Air resistance refers to the mixing of air into the hydraulic oil, which causes the pressure in the system to be unstable, thus affecting the smoothness of the steering operation. Air resistance is usually caused by system leakage or improper filling of hydraulic oil.

● Solution: Check whether there is air leakage in the hydraulic oil circuit and remove the air in the system by exhausting.

7. Loose or damaged belt

● Phenomenon: No steering power and abnormal engine noise.

● Cause: The hydraulic pump is driven by the engine belt. If the belt is loose, slipping or broken, the hydraulic pump will not work properly, causing the steering system to fail.

● Solution: Check the tension of the engine belt. If it is found to be worn or loose, it should be adjusted or replaced in time.

How to identify the signal of hydraulic steering rack failure?

After understanding the possible causes of hydraulic steering rack failure, car owners also need to learn to recognize the early signs of these problems so that they can be dealt with in time before the problem worsens. Here are some common warning signs:

1. Steering wheel becomes heavier: If you feel that turning the steering wheel has become more laborious than usual, especially when driving at low speed or parking, this may be caused by insufficient pressure in the hydraulic system.

2. Abnormal noise: Hearing a squeaking, buzzing or metal friction sound when turning the steering wheel may indicate a problem with the hydraulic pump or steering rack.

3. Sluggish steering response: After turning the steering wheel, the steering response of the wheel becomes slower or inaccurate, indicating that the flow of hydraulic oil is blocked or the steering valve is faulty.

4. Hydraulic oil leakage: If you find red or brown oil stains on the ground, or the hydraulic oil level often drops, this may be a sign of a system leak.

5. Steering wheel vibration: Irregular vibration of the steering wheel during driving usually indicates that there is air blockage in the steering system or contamination of the hydraulic oil.

How to prevent the failure of the hydraulic steering rack?

In order to ensure the normal operation of the hydraulic steering rack, car owners should perform regular inspections and maintenance. Here are some preventive measures:

1. Check the hydraulic oil regularly: The quality and level of the hydraulic oil are critical to the proper functioning of the system. Check the hydraulic oil level regularly as recommended in the vehicle manual and replace any deteriorated or contaminated hydraulic oil promptly.

2. Monitor the belt condition: Check the tension and wear of the engine belt regularly to ensure that the hydraulic pump can function properly.

3. Keep the system clean: Avoid mixing impurities or air into the hydraulic oil and ensure that the hydraulic oil is filled properly.

4. Check the steering system regularly: During vehicle maintenance, especially when changing tires or performing suspension system inspections, the steering system should be thoroughly inspected to ensure that all its components are in good condition.