Does a manual steering rack require a power steering pump?

In the complex mechanical system of a car, the steering system is a vital part. It not only directly affects the driving control and safety, but also reflects the technical level of vehicle design. In modern cars, although more and more models are equipped with power steering systems, manual steering racks are still the core components of many vehicles.

So, what is a manual steering rack? Does it require a power steering pump? This article will reveal the working principle and characteristics of this system for you and answer these key questions.

What is the basic concept of a manual steering rack?

A manual steering rack, also known as a mechanical steering rack, is a device that performs vehicle steering operations in a purely mechanical manner. It does not rely on any hydraulic or electric power-assisting system, but controls the steering of the front wheels through the force directly applied by the driver.

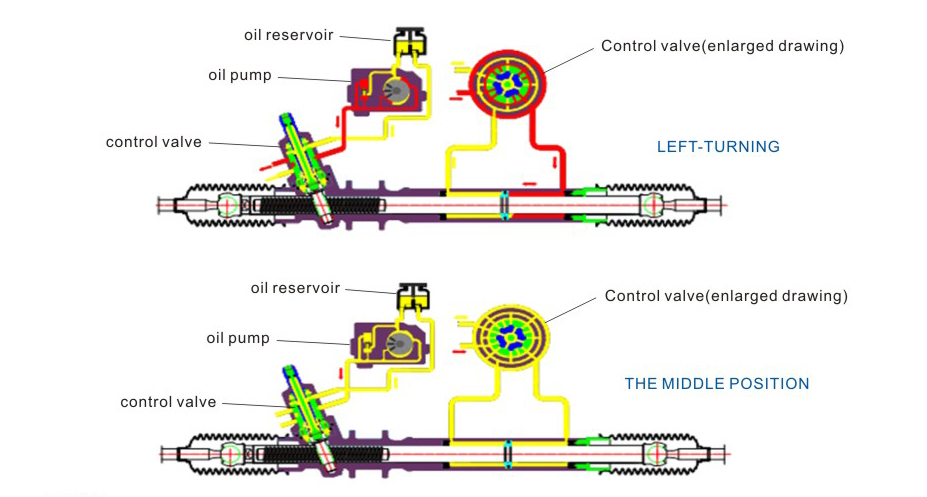

In this system, the steering wheel is connected to the steering rack through the steering column. When the driver turns the steering wheel, the steering column drives the rack to move laterally. This movement converts the rotational motion into linear motion through the meshing of the rack and the gear, thereby turning the wheel. Since the entire process is mechanical transmission, its operation is completely dependent on the driver's power.

How does a manual steering rack work?

The working principle of a manual steering rack can be divided into several main parts:

1. Steering wheel and steering column: The rotational force applied by the driver through the steering wheel is transmitted to the steering column. The steering column is a vertical rod directly connected to the steering wheel, and when the steering wheel turns, the steering column also rotates.

2. Steering gear and rack: The rotational motion of the steering column is transmitted to the rack through the gear. The rack is a horizontally placed bar with a series of tooth structures on its surface. When the gear rotates, the teeth on the gear mesh with the teeth on the rack, converting the rotational motion into linear motion. This process causes the rack to move laterally, thereby driving the wheels to turn.

3. Connecting parts and wheels: The linear motion of the rack is transmitted to the wheel through the connecting rod or ball head tie rod, causing the wheel to rotate on the steering pivot. This rotation determines the steering angle and direction of the vehicle.

What are the characteristics of a manual steering rack?

As a classic mechanical steering system, the manual steering rack has some unique characteristics that make it still popular in specific application scenarios.

1. Simple structure: The design of the manual steering rack is relatively simple, mainly consisting of basic components such as rack, gear, steering column and connecting rod. This simple structure makes it highly reliable and durable with low failure rate.

2. Light weight: Manual steering racks are usually lighter than power steering systems because there is no additional hydraulic pump, electric power assist device or complex electronic control system. This feature reduces the overall weight of the vehicle, thereby improving fuel economy and performance.

3. Intuitive feedback: The manual steering system provides more direct road feel feedback because it does not have a power assist system to filter the force applied by the driver. The driver can clearly feel the road conditions through the steering wheel, so as to control the vehicle more accurately.

4. Low cost: Due to its simple structure, the manufacturing and maintenance costs of manual steering racks are relatively low. Therefore, it is still widely used in some economical vehicles or models that focus on cost control.

Manual steering rack VS. power steering system: Which one is better?

After understanding the basic working principle of the manual steering rack, it is necessary to compare it with the power steering system to better understand its advantages and disadvantages.

1. Assistance requirement: The manual steering rack is completely dependent on the driver's strength, without any form of assistance. This means that at low speeds or when stationary, turning the steering wheel may require more force. The power steering system provides assistance through a hydraulic pump or electric motor, which reduces the driver's operating burden.

2. Control accuracy: Since the manual steering system has no power intervention, the driver can get more direct control feedback and the steering operation is more accurate. This is more advantageous for racing cars or sports vehicles that require precise control.

3. Complexity and maintenance: The power steering system contains more components, such as hydraulic pumps, power cylinders, and electronic control units, so it is more complex and has relatively high maintenance costs. The manual steering rack is easier to maintain and has a low failure rate due to its simple mechanical structure.

4. Driving experience: In daily driving, the power steering system is more comfortable due to its light steering operation experience, especially when driving in the city or parking. The manual steering system is more suitable for drivers who like direct road feel and precise control, and is suitable for use in sports driving or specific environments.

Does the manual steering rack require a power steering pump?

The key to answering this question lies in understanding the function of the power steering pump and the working principle of the manual steering rack. The main function of the power steering pump is to provide hydraulic assistance to the steering system, reducing the force that the driver needs to apply when steering. So does the manual steering rack need this kind of assistance?

The answer is no. The manual steering rack does not require a power steering pump, which is one of the fundamental differences between it and the power steering system. The power steering pump is a key component that provides hydraulic assistance to the hydraulic power steering system. It assists the steering operation through the pressure of the hydraulic oil, reducing the operating burden of the driver. However, in the manual steering system, since its design is purely mechanical in nature and there is no need for hydraulic assistance, a power steering pump is not required.

In fact, if a power steering pump is equipped for a manual steering rack, it completely changes its working principle and makes it a power steering system. Therefore, the power steering pump is incompatible with the manual steering rack, and the two cannot coexist.

What are the application scenarios of manual steering racks?

Although power steering systems have become mainstream in the modern automotive industry, manual steering racks are still used in specific application scenarios. Here are some typical application scenarios:

1. Racing: In racing, precise control and direct road feel feedback are crucial. Manual steering racks are often used in racing due to their high control accuracy and no power interference. The driver can get more direct steering feedback through this system, which helps to make precise control at high speeds.

2. Classic and retro models: In order to maintain the original driving experience, some classic or retro models still use manual steering racks. This is not only a tribute to traditional car design, but also satisfies the pursuit of the original mechanical feeling of driving by a specific group of people.

3. Small and economical vehicles: In some small or economical vehicles that focus on cost control, manual steering racks are still widely used due to their advantages of low cost and low maintenance requirements. For drivers of such vehicles, the simplicity and durability of manual steering systems are more important.

4. Off-road and special-purpose vehicles: In some off-road or special-purpose vehicles, the simplicity, reliability and durability of manual steering racks make them an ideal choice. These vehicles usually need to work for a long time in harsh conditions, so the reliability of the system is particularly critical.