Does General Motors use electric power steering?

In recent years, electric power steering (EPS) has become increasingly popular in the global automotive market and has become one of the steering technologies chosen by many automakers. Compared with traditional hydraulic power steering systems, electric power steering systems are more energy-efficient, sensitive, and have the advantage of reducing emissions. So, as one of the world's largest automakers, does General Motors (GM) use electric power steering technology? The answer is yes.

GM not only uses electric power steering, but it has also applied this technology to multiple models. This article will analyze in detail the background and advantages of GM's use of electric power steering in its products, as well as the development history of GM's steering system, to help readers better understand the wide application and importance of this technology.

What is the development history of GM's steering system?

Founded in 1908, General Motors, as one of the oldest automobile companies in the world, has a technology research and development history that can be regarded as a vane in the industry. In the early days, GM, like most automakers, used a mechanical steering system that relied entirely on the driver's power to control the steering wheel.

Mechanical steering system

The mechanical steering system is a technology widely used in early automobiles. The steering wheel is directly connected to the steering gear, and the driver's steering force is completely transmitted to the wheel through the mechanical structure. Although the mechanical steering system has a simple structure, with the increase in vehicle weight, especially the popularity of large cars and trucks, the disadvantages of mechanical steering in actual driving are becoming increasingly apparent. The driver needs to use greater force when steering, especially at low speed or parking, turning the steering wheel is particularly difficult.

Hydraulic power steering system

In order to solve the shortcomings of the mechanical steering system, General Motors began to adopt the hydraulic power steering system (Hydraulic Power Steering) in the mid-20th century. Hydraulic Power Steering uses the engine to drive the hydraulic pump to generate hydraulic oil pressure to provide power to the steering wheel, greatly reducing the driver's operating burden.

General Motors has used hydraulic power steering technology on many classic models, such as Chevrolet, Cadillac and other brands. Especially for large SUVs and pickup trucks, hydraulic power steering technology plays a key role in steering flexibility and comfort.

Electric power steering system

With the improvement of environmental awareness, the development of vehicle electrification and the demand for fuel economy, General Motors has gradually transformed to electric power steering system. Electric power steering system no longer relies on hydraulic pumps and their complex mechanical structure, but provides steering assistance through electric motors. The application of this system not only saves fuel, but also can automatically adjust the power assistance according to the vehicle speed to achieve more precise steering control. Therefore, General Motors has gradually applied electric power steering technology to many of its models since around 2010.

Why does General Motors use electric power steering system?

The transition of General Motors' steering system from hydraulic power assistance to electric power assistance reflects the technological upgrading trend of the global automotive industry. So why does General Motors use electric power steering system? The main reasons include the following:

Fuel economy

One of the biggest advantages of electric power steering system over hydraulic power steering system is improved fuel economy. Hydraulic power steering system relies on engine-driven hydraulic pump, which means that even when the vehicle does not need steering assistance, the hydraulic pump is still running and consuming fuel. Electric power steering system only works when assistance is needed, greatly reducing unnecessary energy consumption.

According to relevant research, electric power steering systems can save about 3-5% of fuel consumption compared to traditional hydraulic power steering systems. For global companies like GM, fuel economy not only affects consumers' car use costs, but also involves increasingly stringent environmental regulations and carbon dioxide emission standards.

Reduce maintenance costs

Hydraulic pumps, hydraulic oil pipes, oil seals and other components in hydraulic power steering systems will wear and leak during long-term use, resulting in frequent maintenance and replacement. The electric power steering system has a relatively simple structure and does not require hydraulic oil and hydraulic pipes, thereby reducing failure points and reducing the overall maintenance cost of the vehicle.

For consumers, reducing the need for maintenance of the hydraulic system means a reduction in the total cost of ownership (TCO) of the vehicle, which is an important consideration for GM when targeting the mass market.

Flexibility and precise control

The electric power steering system can dynamically adjust the steering assist according to different driving conditions. For example, when driving at high speeds, the system will reduce the assist to enhance the stability of the steering wheel; when driving at low speeds or parking, the system will provide more assist to make it easier for the driver to control. This flexible control is difficult to achieve with traditional hydraulic power steering systems.

In addition, the electric power steering system can also be integrated with other electronic control systems in modern cars, such as Lane Keep Assist and automatic parking systems, which further enhances the intelligence level of the vehicle. For GM, the use of electric power steering systems can enable its models to have more intelligent driving functions and enhance market competitiveness.

Responding to environmental regulations

In recent years, environmental regulations around the world have become increasingly stringent, requiring automakers to reduce vehicle carbon dioxide emissions. The continuous operation of the hydraulic power steering system not only increases fuel consumption, but also increases engine load, thereby increasing carbon emissions. The electric power steering system can significantly reduce the overall energy consumption and emissions of the vehicle because it only operates when needed.

As a global company, GM must respond to environmental requirements from all over the world, especially strict emission regulations in Europe, North America and China. The use of electric power steering systems can help GM reduce production and maintenance costs while complying with regulations.

What models of GM use electric power steering?

GM has multiple brands covering a wide range of markets from economical family cars to luxury models and commercial vehicles. In recent years, GM has popularized electric power steering systems in many models, including the following major brands:

Chevrolet

As GM's main brand, Chevrolet is positioned in the mass market. In recent years, Chevrolet has adopted electric power steering systems in many of its cars, SUVs and trucks. For example, models such as Chevrolet Cruze, Malibu and Equinox are equipped with electric power steering systems.

Cadillac

As GM's luxury brand, Cadillac focuses on the high-end market. Many Cadillac models not only use electric power steering systems, but also combine them with autonomous driving assistance systems to provide a more advanced driving experience. Models such as Cadillac CT6 and XT5 are equipped with electric power steering systems and are closely integrated with the Super Cruise driver assistance system.

GMC

GM's commercial vehicle and truck brand GMC has also gradually introduced electric power steering systems into its product line. For GMC pickup trucks and SUVs, the application of electric power steering not only improves driving comfort, but also further improves fuel economy by reducing fuel consumption.

What are the application challenges of electric power steering system?

Despite the many advantages of electric power steering system, its application also faces some challenges. For large manufacturers such as GM, cost control, technical maturity and consumer acceptance of electric power steering are all factors that need to be considered.

System complexity

Although the electric power steering system reduces the complexity of the hydraulic system, its electronic components and sensors have higher design and integration requirements. Especially in high-end models, electric power steering needs to work with multiple electronic control systems, which puts higher requirements on system reliability and safety.

Failure risk

Compared with traditional hydraulic systems, the electronic components of the electric power steering system are more sensitive, especially under extreme temperature conditions, and may fail. GM must ensure the durability and safety of its EPS system through strict quality control and testing.

Cost control

Although the electric power steering system can reduce long-term maintenance costs, its initial installation cost is high. When promoting this technology to the mass market, GM needs to strike a balance between cost and performance to ensure consumer acceptance.

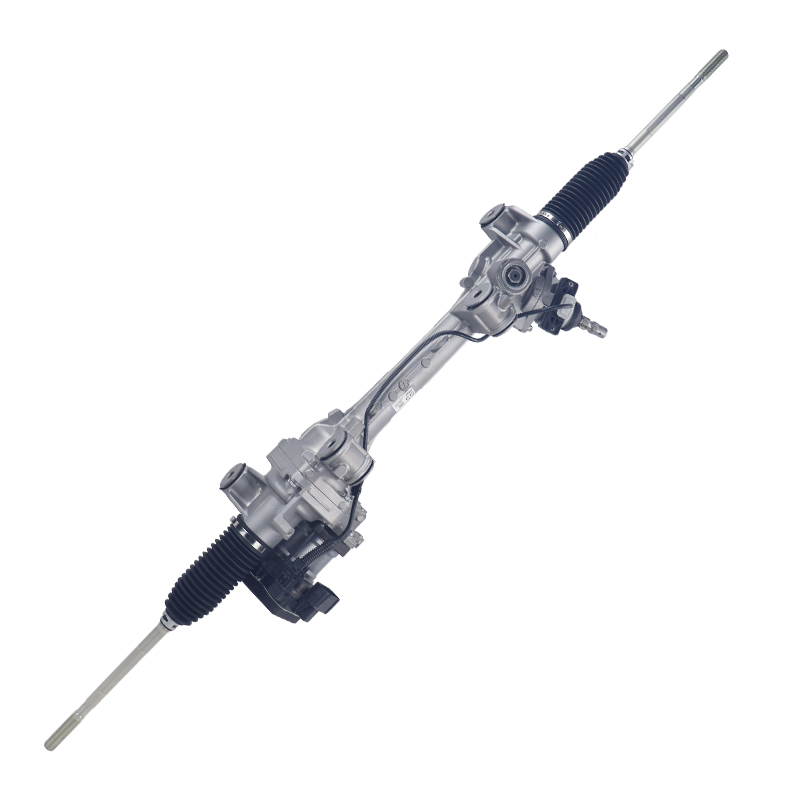

DKM Company is a leading manufacturer and exporter of power steering rack based in China. With a production facility spanning over 20,000 square meters and a capacity of 300,000 units durability annually, we deliver premium-quality products to domestic OEMs, national dealers, and international markets like the USA, Italy, and Southeast Asia. Our advanced manufacturing process includes 280+ CNC and heat treatment machines, ensuring the highest standards of precision and hydraulic power. We offer a wide range of gear-and-rack and hydraulic power steering systems compatible with global brands such as Toyota, Honda, Hyundai, Mitsubishi, Buick, and Volkswagen. Contact us for a free quote today!