How does the electric power steering rack assist steering control?

With the continuous development of automobile technology, the traditional hydraulic power steering system is gradually replaced by the electric power steering system (EPS). As one of the important components, the electric power steering rack plays an important role in realizing the steering control of modern automobiles. Compared with the traditional hydraulic steering system, the electric steering system has higher energy efficiency, precise control and better feedback to the driver. The electric power steering rack is one of the core components in this system and directly participates in the steering operation of the car.

This article will discuss in detail how the electric power steering rack assists steering control, analyze its working principle, function and impact on the driver's control experience.

What is the electric power steering system (EPS)?

The electric power steering system (EPS) is a steering system that provides power assistance through an electric motor, which replaces the traditional hydraulic power steering (HPS) system. Unlike the hydraulic system, the electric system does not require a hydraulic pump and fluid to generate power assistance, but relies on the electric motor to adjust through the electronic control unit (ECU). Therefore, the EPS system is not only more energy-efficient, but also provides more precise steering control and response.

In the electric power steering system, the electric power steering rack is an important component for achieving steering control. It works with motors, electronic control units, sensors and other components to give the driver an easy and flexible control experience when manipulating the steering wheel.

What are the structures of electric power steering racks?

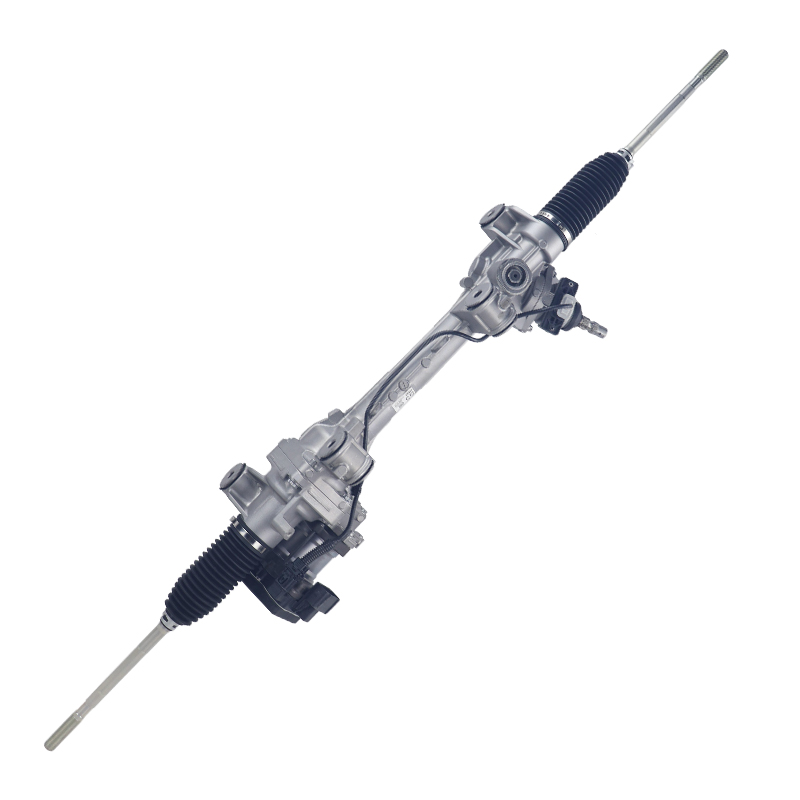

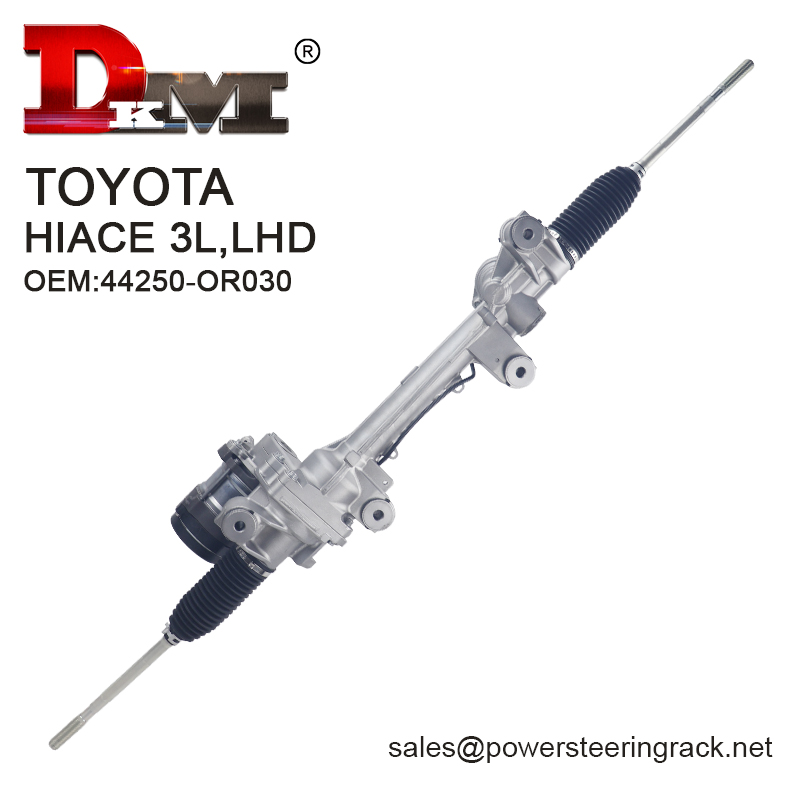

The electric power steering rack system consists of several main parts: steering wheel, steering shaft, rack, gear and motor. Among them, rack and gear are key components that convert the force of the driver turning the steering wheel into mechanical force and transmit it to the wheels.

● Rack: Usually a long metal component with gear teeth on its surface. When the steering wheel turns, the steering shaft drives the rack to move along the axial direction.

● Gear: Usually a component installed on the steering shaft, the gear meshes with the rack. When the steering wheel is turned, the gear transmits the rotational force to the rack, thereby causing the wheel to turn.

● Motor: The motor is a key component of the electric power steering system. It is driven by electricity to generate steering assistance. The motor adjusts the power assistance according to parameters such as the driver's control strength and vehicle speed.

What is the working principle of the electric power steering rack?

The working process of the electric power steering rack is divided into multiple links. The following is the basic principle of how the electric power steering rack assists steering control:

1. The driver turns the steering wheel

When the driver turns the steering wheel, the steering shaft is connected to the rack through the gear. The turning force applied by the driver is transmitted to the rack through the gear, which then pushes the rack to move along the axial direction. The movement of the rack drives the steering connection components, which in turn causes the wheels to turn.

In traditional hydraulic steering systems, the steering pump provides hydraulic assistance to reduce the turning resistance of the steering wheel, while in the electric power steering rack, the electric motor provides steering assistance through electrical energy.

2. The electric motor provides assistance

When the driver starts to turn the steering wheel, the steering sensor monitors the amount of steering wheel rotation and the steering force. This information is transmitted to the electronic control unit (ECU), and the ECU determines the size of the electric motor's assistance based on vehicle speed, driver operation force and other real-time data.

The electric motor starts according to the instructions of the ECU and provides the necessary assistance through the cooperation of the rack and gear. The assistance provided by the electric motor is adjustable in real time, so it can be adjusted according to different driving environments (such as lighter at low speed and more stable at high speed).

3. Adjust the power assist

In the electric power steering rack, the power assist can be adjusted according to the actual situation. At low speeds, steering requires less force, and the system will provide greater power assist, allowing the driver to easily control the steering wheel; at high speeds, in order to ensure stability and the driver's sense of control, the system will reduce the power assist, so that the steering wheel has a certain sense of weight and avoids overly sensitive reactions.

This ability to dynamically adjust the power assist enables the electric power steering system to provide the most appropriate control feel according to different driving scenarios, thereby improving driving comfort and safety.

4. Feedback and adjustment

The electric power steering rack is not just a mechanical transmission system, it can also adjust the feel of the steering wheel through motor and sensor feedback. Steering feedback on the steering wheel is an important part of the system, which can help the driver perceive the interaction between the wheels and the road.

Through real-time feedback, the system can provide different road feel information to the driver. For example, when making a sharp turn, the system will adjust the power assist to make the steering wheel more stable, ensuring that the driver can clearly feel the changes in the road surface and make more precise control.

What are the advantages of an electric power steering rack?

Electric power steering racks have several advantages in assisting steering control, making them an indispensable technology in modern cars.

1. High energy efficiency and energy saving

Electric power steering racks are more energy-efficient than traditional hydraulic systems. In hydraulic systems, the hydraulic pump needs to be powered by the engine, which often increases the burden on the engine. The electric power steering system uses an electric motor to provide power, which means that power is consumed only when needed, and the system can stop working when steering power is not needed, thereby reducing energy consumption.

2. Precise steering control

The electric power steering rack system can dynamically adjust the power assistance according to different driving needs. For example, at low speeds, the system provides more power assistance, allowing the driver to easily turn the steering wheel; while at high speeds, the system reduces the power assistance, making the steering wheel heavier and enhancing driving stability. This precise power assistance adjustment allows the driver to experience a more comfortable and safe driving experience.

3. Higher reliability and lower maintenance costs

The electric power steering rack has a simpler structure and does not have complex components such as pumps, pipes and fluids in the hydraulic system. This makes the electric system less prone to failure and does not require regular replacement of hydraulic oil, reducing the system's maintenance costs and failure rate in long-term use.

4. Increase the space and flexibility of the vehicle

Since the electric power steering system does not require the hydraulic pumps and pipes in the traditional hydraulic system, vehicle manufacturers can design the layout of the vehicle more flexibly and save space. This makes the electric power steering rack system particularly suitable for the application of modern compact cars and electric vehicles.

5. Easy to integrate with other intelligent systems

The electric power steering system can be easily integrated with other vehicle intelligent systems. For example, intelligent driving systems such as autonomous driving technology, lane keeping assist system (LKA), adaptive cruise control (ACC), etc. all require precise steering control, and the electric power steering rack system can provide the required accuracy and response speed, thereby achieving a more intelligent driving experience.

What are the technical challenges of electric power steering rack?

Although the electric power steering rack system has obvious advantages in many aspects, it also faces some technical challenges. For example, the power and control accuracy of the motor need to be further improved to cope with different road conditions and driving needs; at the same time, the reliability and safety of the system are also important issues of concern to car companies and consumers.

However, with the continuous development of automotive technology, the performance and function of the electric power steering rack will continue to improve, and it will play an increasingly important role in future intelligent driving.