How often does the power steering pump need to be replaced?

As an important part of modern cars, the power steering system has the core task of providing assistance to the driver when steering, making the vehicle's operation easier and more comfortable. In this system, the power steering pump plays a vital role. The power steering pump transmits power through the hydraulic system, reducing the burden on the driver to turn the steering wheel. However, as the vehicle is used, the performance of the power steering pump will gradually decline, and may even fail.

This article will discuss in detail the replacement cycle of the power steering pump and the key factors affecting its life, to help car owners better understand when to consider replacing the power steering pump.

What are the basic functions and importance of the power steering pump?

The main function of the power steering pump is to provide hydraulic pressure to the steering system, making the steering operation of the vehicle easier. It drives the hydraulic pump to produce high-pressure hydraulic oil through the mechanical energy provided by the engine, thereby providing the necessary power for the steering rack or gear. When the driver turns the steering wheel, the hydraulic oil provided by the power steering pump flows to the steering system, making the wheels turn more smoothly.

The power steering pump is particularly important when driving at low speeds or parking, because it can significantly reduce the force required by the driver to turn the steering wheel, avoiding unnecessary fatigue and potential dangers caused by difficult maneuvers. Therefore, the normal operation of the power steering pump is essential for the driving safety and comfort of the vehicle.

What is the life of the power steering pump? What factors affect its life?

As a mechanical device, the life of the power steering pump is not constant, but is affected by many factors. The mileage of the vehicle is an important factor affecting the life of the power steering pump. Generally, the design life of the power steering pump is equivalent to the overall design life of the vehicle, which is about 150,000 to 200,000 kilometers. However, in actual use, the life of the power steering pump may vary depending on the vehicle's use environment and driving habits.

Vehicles that often drive in extreme temperatures, high dust environments or on rough roads have a greater load on their power steering pumps and wear faster. In this case, the pump body and hydraulic oil may age faster, shortening the service life of the pump. Secondly, the power steering pump relies on hydraulic oil for lubrication and cooling. If the hydraulic oil is of poor quality or has not been replaced for a long time, wear and corrosion may occur inside the hydraulic system, which will affect the life of the power steering pump. Regular inspection and replacement of hydraulic oil can effectively extend the service life of the pump.

In addition, regular maintenance of the power steering system, including checking the hydraulic oil level, cleaning the hydraulic oil filter, and checking the pump body and pipeline for oil leaks, can extend the service life of the power steering pump to a certain extent. Systems that lack maintenance are more likely to fail, causing premature damage to the pump body.

How often does the power steering pump need to be replaced?

Depending on the above factors, the replacement cycle of the power steering pump also varies. Generally speaking, the replacement cycle of the power steering pump should be comprehensively judged based on the use of the vehicle, mileage, and the working status of the system. Under normal circumstances, the design life of the power steering pump is 150,000 to 200,000 kilometers. When the vehicle mileage reaches this range, even if the power steering pump has not yet shown obvious failures, the owner should consider checking it and replacing it if necessary. As the mileage increases, the wear inside the pump body may gradually increase, affecting the normal operation of the system.

In addition, when the power steering pump begins to have problems such as abnormal noise, reduced power assistance, or oil leakage, the owner should check it immediately. These phenomena are usually signs of pump body wear or unstable internal pressure in the system. If the problem is serious and cannot be solved by simple repairs, the owner should consider replacing the power steering pump to ensure the normal operation of the steering system.

For vehicles that are often driven in harsh environments or have not been maintained for a long time, the owner should conduct a comprehensive inspection of the power steering system every 50,000 kilometers or every two years to detect and solve potential problems in time. In some cases, even if the power steering pump has not reached its design life, it may need to be replaced in advance due to long-term overload operation or lack of maintenance.

What is the necessity of replacing the power steering pump?

Replacing the power steering pump is not only to restore the vehicle's steering power, but also to avoid potential safety hazards. The hydraulic power assist provided by the power steering pump is essential for the control of the vehicle. Insufficient or failed power assist may make steering operations difficult, especially when driving at low speeds, parking or emergency steering, which can easily cause accidents. Timely replacement of aging or faulty power steering pumps can ensure that the vehicle maintains good handling performance under various driving conditions.

Secondly, when the power steering pump fails and is not replaced in time, other parts of the hydraulic system, such as the steering rack, gears or hydraulic lines, may be damaged due to abnormal pressure or insufficient lubrication. This will lead to a significant increase in repair costs, and may even require the replacement of the entire steering system. Replacing the faulty pump body in time can avoid these unnecessary losses. In addition, a properly working power steering pump can significantly improve the driving comfort of the vehicle, especially in congested urban road conditions, where frequent steering operations require more stable hydraulic assistance. Replacing an old or faulty power steering pump can restore the smooth handling of the vehicle and enhance the driving experience.

Process and precautions for replacing a power steering pump

The replacement of a power steering pump is relatively complicated and usually requires professional maintenance personnel to operate. When replacing a power steering pump, a pump body that matches the original vehicle model should be selected. Using an unqualified pump body may cause the hydraulic system to work abnormally and affect steering performance. In addition, it is recommended to choose original parts with reliable quality or certified replacements to ensure the durability and performance of the pump body.

Secondly, when replacing a power steering pump, the hydraulic system should be thoroughly cleaned, especially the old hydraulic oil and impurities in the pipeline and steering rack. The new hydraulic oil should meet the vehicle manufacturer's specifications and be refilled after the new pump body is installed. Cleaning the system helps prevent impurities from entering the new pump body and affecting its life and working effect. Before installing the new pump body, check the condition of the hydraulic lines and connectors to ensure that there is no wear, cracks or oil leakage. If any problems are found, the relevant parts should be replaced or repaired in time to avoid oil leakage or hydraulic instability after installation.

After installing the new pump body, the air in the system should be exhausted through a special exhaust procedure to avoid air residue affecting the hydraulic power effect. After the exhaust is completed, add new hydraulic oil as required by the manufacturer and check whether the liquid level meets the standard. This process should be carried out when the vehicle is cold to ensure that the hydraulic oil temperature is normal and avoid overheating and damage to the new pump body. Finally, after replacing the power steering pump, a test drive should be carried out to check whether the system is operating normally. In particular, pay attention to whether the steering operation is smooth, whether there is any abnormal sound or insufficient power assistance. If any abnormality is found, the operation should be stopped immediately and the pump body installation and hydraulic system condition should be rechecked.

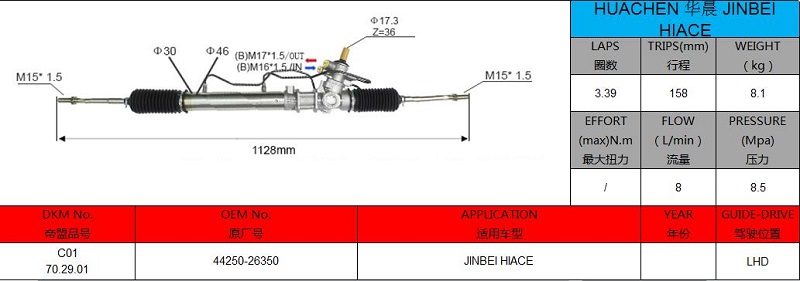

DKM, a leading Chinese manufacturer, specializes in high-quality automotive power steering systems. With over 25 years of experience, we supply gear rack steering systems designed for durability and compatibility with global vehicle brands. Our products are exported to markets across the USA, Italy, and Southeast Asia. We offer factory-direct prices, customizable options, and promotional discounts to support your purchasing goals. Contact us today for more information about our extensive product range and competitive pricing.