In which year did the Electric Power Steering come out?

The advent of the Electric Power Steering (EPS) system marks a major breakthrough in automotive technology. It changes the working mode of the traditional Hydraulic Power Steering (HPS) and provides steering assistance to the vehicle in a more efficient and intelligent way. The introduction of EPS not only improves the driving experience, but also brings new possibilities for the overall design of the vehicle by reducing the use of mechanical components and improving energy efficiency.

So, in which year did the Electric Power Steering system come out? This article will take you through the history of the birth of this technology and explore its entire process from concept to widespread application.

Background of the birth of the Electric Power Steering System

Before understanding the specific year of the birth of the Electric Power Steering System, it is necessary to review the development history of the automotive steering system.

1. Early mechanical steering system

In the early days of the birth of automobiles, vehicles used the simplest mechanical steering system. The system transmits the driver's operation directly to the wheels through a mechanical connection. Although this system is simple, the driver needs to spend more effort to turn the steering wheel when the vehicle is heavy, especially at low speed or when parking.

2. The introduction of hydraulic power steering

In order to solve the shortcomings of mechanical steering systems, hydraulic power steering systems gradually became popular in the mid-20th century. Hydraulic power steering systems provide additional power through hydraulic pumps to help drivers easily operate the steering wheel. Since the 1950s, hydraulic power steering systems have become mainstream, and almost all modern cars have adopted this method until the emergence of more advanced electric power steering systems.

3. The birth of electric power steering needs

Although the hydraulic power steering system solves the problem of laborious steering wheel operation, it still has some defects. For example, the hydraulic system always requires the hydraulic pump to work, which means that it constantly consumes the energy of the engine, thereby reducing fuel economy. In addition, the complexity of the hydraulic system and its dependence on hydraulic oil also increase maintenance costs. With the advancement of electronic technology and the increasing demand for vehicle intelligence, people began to explore more efficient and intelligent steering systems, which laid the foundation for the emergence of electric power steering systems.

In which year did the electric power steering system come out?

The real time of the electric power steering system can be traced back to the early 1990s.

1993: The first electric power steering system in the Fiat Punto

The first large-scale application of electric power steering was in 1993, when Italian car manufacturer Fiat introduced this innovative technology on its Punto model. The Fiat Punto was the world's first mass-produced car equipped with electric power steering. This system provides power assistance through an electric motor, eliminating the need for hydraulic pumps and hydraulic oil, making the steering system more efficient and easier to maintain.

This breakthrough technology not only solves the problem of energy waste in hydraulic systems, but also improves the response speed and accuracy of the steering system. Especially when driving at low speeds or parking, the electric power steering system can provide precise power assistance based on the actual situation of the vehicle, thereby significantly reducing the operating burden on the driver.

Advantages of electric power steering system

Compared with hydraulic power steering system, electric power steering system has many advantages:

● High efficiency and energy saving: Electric power steering system only provides power assistance when needed, while the hydraulic system is always running, so EPS system can significantly reduce the vehicle's energy consumption and improve fuel economy.

● Reduced mechanical loss: Since hydraulic pumps and related hydraulic components are no longer used, the mechanical structure of the electric power steering system is simpler, reducing the risk of wear and failure.

● Intelligent adjustment: The electric power steering system can be intelligently adjusted according to the vehicle's speed and steering angle, making the driving experience smoother. Especially when driving at high speeds, the power will be automatically reduced to provide better stability and road feel.

What is the development history of the electric power steering system?

Since the Fiat Punto first introduced the electric power steering system in 1993, EPS technology has spread rapidly around the world and gradually replaced the hydraulic power steering system. The following are the main development milestones of the electric power steering system in the past few decades.

Late 1990s to early 2000s

In the late 1990s, more and more automakers began to realize the potential of electric power steering systems. Because EPS can not only improve the energy efficiency of vehicles, but also can be intelligently adjusted through electronic control units (ECUs), it has gradually become a standard configuration for high-end models.

2000s: Wider application

Entering the 21st century, with the further development of electronic technology and automotive control systems, electric power steering systems have been more widely used in the mid-to-high-end automotive market. Luxury car brands such as BMW, Mercedes-Benz, and Audi have all made EPS a standard feature of their main models. The electric power steering system of this period not only improved driving comfort, but also greatly reduced the common failures and maintenance requirements of hydraulic systems.

2010s to present: the full popularization of electric power steering

By the 2010s, electric power steering systems have become almost standard features of most new cars around the world. Especially in new energy vehicles (such as electric vehicles and hybrid vehicles), electric power steering systems have become an indispensable part due to their dependence on electricity rather than hydraulic pumps. Today, the application of EPS systems is not limited to luxury cars and mid-to-high-end models. Almost all family cars, SUVs and even commercial vehicles generally adopt this technology.

What are the technical advantages of electric power steering systems?

Fuel economy

Electric power steering systems can significantly improve fuel economy compared to traditional hydraulic systems. Because hydraulic systems require the engine to drive the hydraulic pump, it always consumes the engine's energy, while electric power steering systems only start the motor when needed, saving fuel.

Intelligent control

Another significant advantage of electric power steering systems is their intelligent control capabilities. Through sensors and electronic control units, EPS can dynamically adjust the power assist according to the actual driving conditions of the vehicle. For example, when the vehicle is driving at low speed, the system will increase the power assist to reduce the driver's operating burden; while when driving at high speed, the system will reduce the power assist to provide a more stable control feel.

Reduce maintenance costs

The traditional hydraulic power steering system requires regular replacement of hydraulic oil, and the complex structure of the hydraulic system makes it prone to oil leakage and other faults after long-term use. The electric power steering system does not require hydraulic oil and has a simpler structure, which greatly reduces maintenance costs and repair frequency.

Future technological evolution of electric power steering system

Although the electric power steering system has become the mainstream of the automotive industry, the steering system is still evolving with the continuous advancement of technology. The future steering system may further integrate more intelligent functions, such as combining with the autonomous driving system to achieve more advanced driving assistance functions.

At present, some high-end car brands are already exploring the Steer-by-Wire system, which eliminates the traditional mechanical connection and controls the steering completely through electronic signals. This means that the steering system can be more flexibly integrated with other vehicle control systems to achieve a more precise and personalized control experience.

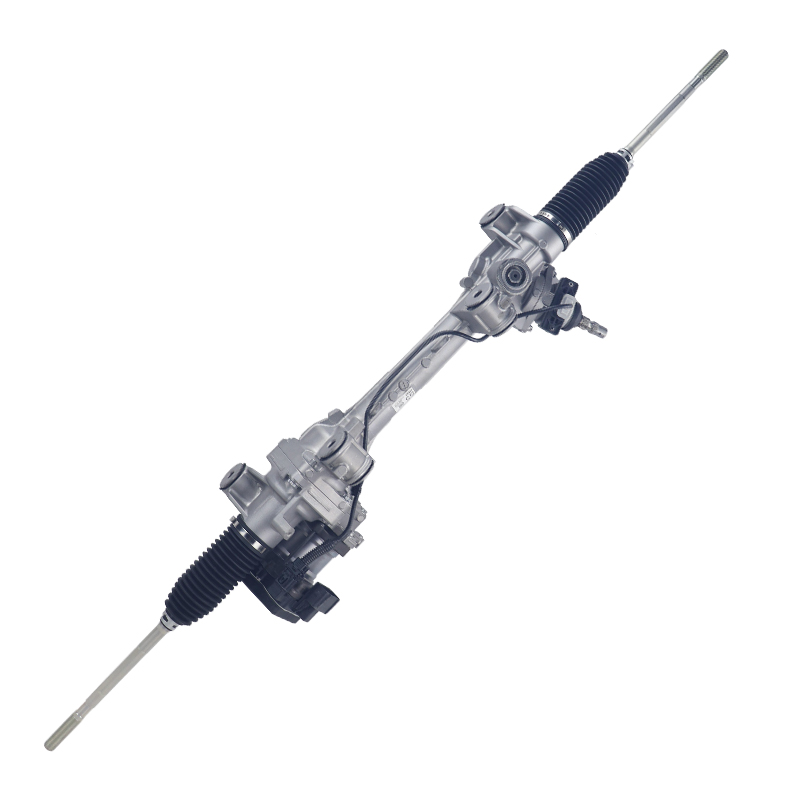

As a recognized leader in the automotive parts industry, DKM specializes in delivering premium power steering systems to buyers worldwide. Since 1996, we have been manufacturing high-quality gear rack steering systems for vehicles from top brands like Toyota, Honda, Hyundai, and Mitsubishi. Our factory, spanning over 20,000 square meters, is equipped with advanced automation and 280+ CNC machines, enabling us to produce 300,000 units annually. We serve markets in the USA, Italy, Russia, Southeast Asia, and beyond, offering competitive wholesale prices, custom solutions, and promotional discounts for bulk orders. At DKM, we pride ourselves on fast delivery, exceptional customer service, and innovative solutions tailored to meet your specific needs. Contact us today for detailed quotes and experience the DKM difference.