Is rack and pinion the most common steering system?

The steering system of a car is an important part of vehicle control. Its main function is to accurately transmit the driver's steering instructions to the wheels, thereby controlling the direction of the vehicle. Among the various steering systems, the racks and pinions steering system has long been widely used in various types of vehicles due to its simple structure, sensitive response and relatively low cost.

This article will explore whether the rack and pinion steering system is still the most common steering system and analyze whether this system is still widely used in modern vehicles.

How does the rack and pinion steering system work?

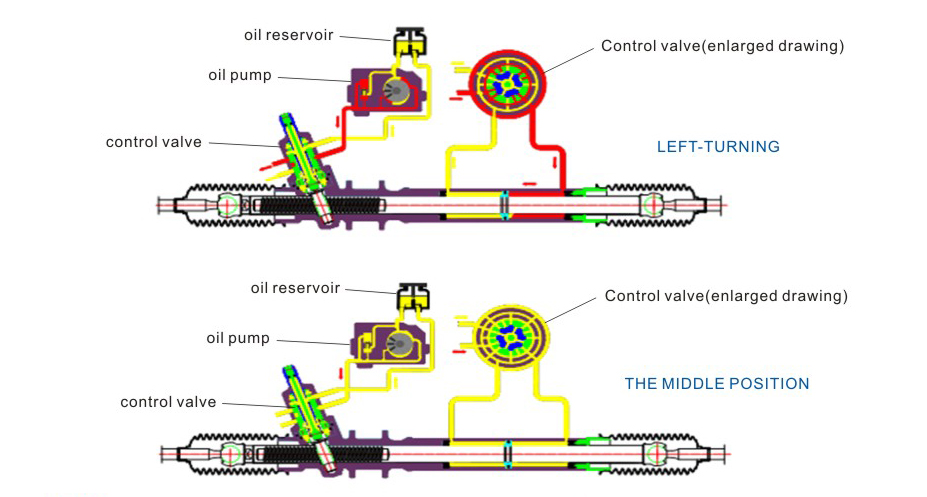

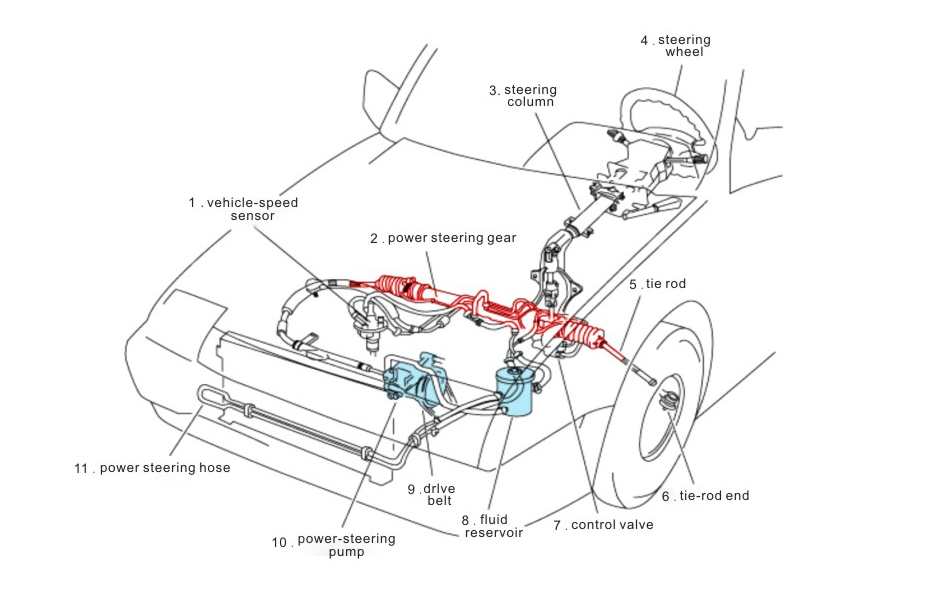

The rack and pinion steering system is a mechanical transmission system that controls the steering of the wheels by converting the rotational motion of the steering wheel into the linear motion of the rack. Specifically, when the driver turns the steering wheel, the pinion (commonly called the "gear") meshes with the rack connected to the steering wheel shaft, and the rotation of the gear drives the rack to move left and right, thereby driving the wheels to turn. Due to this direct mechanical connection, the rack and pinion steering system has high steering accuracy and good road feedback, and the driver can clearly perceive the road conditions and the turning angle of the wheel.

Is rack and pinion the most common steering system?

Historical status of rack and pinion steering system:

During the development of the automobile industry in the 20th century, the rack and pinion steering system gradually became one of the most mainstream steering systems. Especially from the 1970s to the 1990s, with the popularity of front-wheel drive cars, the rack and pinion steering system was widely used due to its compact design and low manufacturing cost. This system not only saves space in the front of the vehicle, but also enables more direct steering control, so it has become the first choice for small and medium-sized passenger cars.

In contrast, traditional steering systems such as worm and sector steering gears and recirculating ball steering gears are more complex in structure, larger in size, more expensive, and inferior to rack and pinion steering systems in terms of control accuracy and road feedback. These factors led to the rapid dominance of rack and pinion steering systems in the passenger car sector, becoming the most common steering system at the time.

Are rack and pinion steering gears still used today?

Although rack and pinion steering systems were once one of the most common steering systems, their dominance has changed in the modern automotive industry. Although rack and pinion steering systems are still widely used in passenger cars and small commercial vehicles, other types of steering systems, such as recirculating ball steering systems and Electric Power Steering (EPS) systems, have gradually taken over the market in some high-end models, heavy vehicles and off-road vehicles.

1. Application in passenger cars: In modern passenger cars, rack and pinion steering systems are still the mainstream, especially in compact and mid-size cars, SUVs and crossovers. The reason why this system is dominant in these models is its compact design, light weight, low production cost and good steering control performance. At the same time, with the development of hydraulic power steering and electronic power steering technology, the control performance of racks and pinions steering systems has been further improved, and drivers can enjoy a more relaxed steering experience while maintaining control accuracy.

2. Application in large and heavy vehicles: For large commercial vehicles, heavy trucks and off-road vehicles, due to their weight and special requirements of the use environment, more durable recirculating ball steering systems are usually used. The recirculating ball steering system performs better in carrying heavy loads and coping with harsh road conditions. Although the steering feedback is vague, it can provide higher torque output, so it is suitable for heavy vehicles. In some high-end luxury cars, in order to improve driving comfort and precision, electronic power steering systems are also used, gradually replacing traditional rack and pinion steering systems.

3. Application in modified cars and racing cars: In the field of modified cars and racing cars, rack and pinion steering systems are still very popular. Such vehicles usually require high-precision steering control and excellent road feedback. Rack and pinion systems can meet these requirements, so they are widely used in modified cars and racing cars. Drivers can further improve the vehicle's steering performance by changing the gear ratio or improving other parts of the steering system.

What are the advantages of rack and pinion steering systems?

Despite competing with other types of steering systems, rack and pinion steering systems still have some unique advantages that make them irreplaceable in many applications.

1. Simple structure: The rack and pinion steering system has a relatively simple structure, mainly consisting of racks, gears, bearings and connecting rods, with a small number of parts and easy maintenance. This simplicity not only reduces manufacturing and maintenance costs, but also improves the reliability of the system.

2. Light weight and high space utilization: Compared with other steering systems, rack and pinion steering systems are lighter and take up less space. This is especially important for front-wheel drive vehicles because it can maximize the use of front space, reduce vehicle weight and improve fuel efficiency.

3. Accurate steering feedback: The steering feedback provided by the rack and pinion steering system is direct and clear, which means that the driver can better perceive the interaction between the vehicle and the road. This is especially important for driving scenarios that require precise control, such as high-speed driving or curve driving.

4. Cost-effectiveness: Rack and pinion steering systems are relatively inexpensive to produce due to relatively mature manufacturing processes and the use of fewer materials, making them suitable for mass-produced ordinary passenger cars. This allows automakers to maintain reasonable vehicle prices while providing good handling performance.

What are the challenges facing rack and pinion steering systems?

Despite its many advantages, rack and pinion steering systems also face some challenges and limitations. The design of rack and pinion steering systems determines that it is more suitable for light and medium-duty vehicles. For heavy trucks and off-road vehicles that require higher torque output, rack and pinion systems may not provide sufficient power support, so other types of steering systems are needed to meet the needs.

Secondly, without a power assist device, rack and pinion steering systems may seem too heavy, especially when driving at low speeds or parking. Therefore, hydraulic or electronic power assist systems are usually indispensable, otherwise the driver may find it difficult to steer. In addition, for some drivers, the road feedback provided by rack and pinion steering systems may be too obvious, especially when driving on uneven roads. Although this strong feedback improves handling precision, it may also increase driving fatigue, especially during long driving.

What are the application prospects of rack and pinion steering systems?

Without discussing future trends, it is clear that rack and pinion steering systems, as a mature mechanical steering solution, still have important application value in modern vehicles. It continues to be widely used in passenger cars and light commercial vehicles due to its simplicity, efficiency and reliability.

At the same time, with the advancement of vehicle manufacturing technology and the increase in drivers' demand for control experience, rack and pinion steering systems are gradually combined with other technologies in the application process, such as hydraulic power and electronic power systems, to further improve the performance and comfort of the steering system.

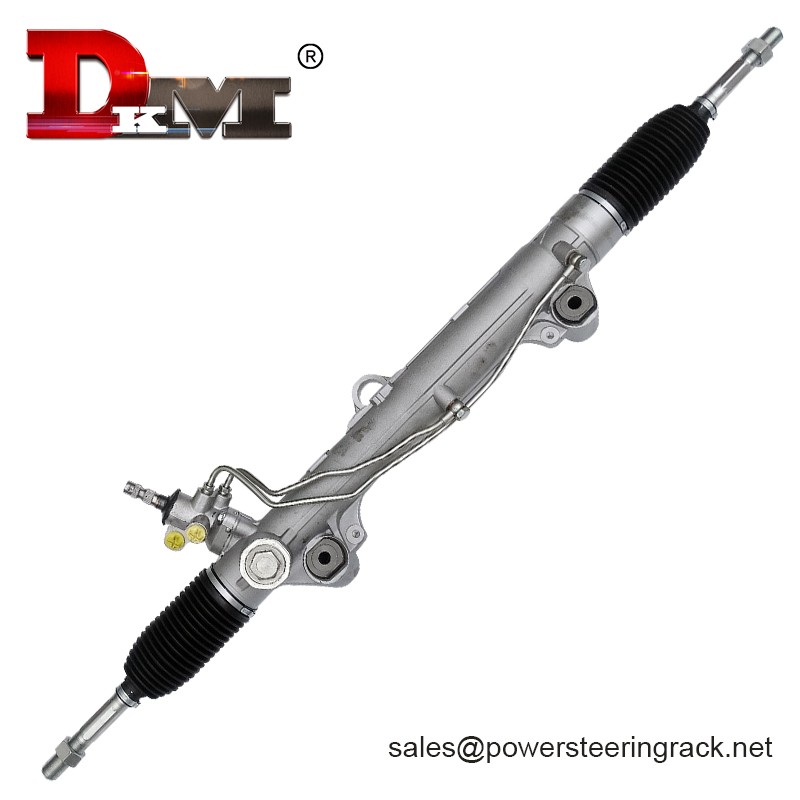

Guangdong Diamond Auto Parts Co., Ltd. (DKM Company) is a trusted Chinese manufacturer specializing in high-quality power steering systems for a diverse range of vehicles, including European, American, Japanese, and Korean brands. With over 28 years of expertise, we export to markets such as the USA, Italy, Southeast Asia, and the Middle East. Our factory covers more than 20,000 square meters and is equipped with over 280 advanced CNC and heat treatment machines, enabling a production capacity of 300,000 units annually. We offer gear-and-rack steering systems, hydraulic power steering systems, and customized solutions for major brands like Toyota, Honda, Mitsubishi, Hyundai, Buick, and Isuzu. At DKM, we combine precision engineering with competitive pricing, making us the preferred supplier for OEMs, distributors, and dealerships worldwide. Contact us today for wholesale prices, exclusive discounts, or customized quotes to meet your purchasing needs.