What effect does deteriorated hydraulic oil have on the steering rack?

As one of the core components of the hydraulic steering rack, the quality and performance of hydraulic oil are crucial to the normal operation of the entire system. However, many car owners lack sufficient knowledge about whether hydraulic oil will deteriorate and the possible impact of deteriorated hydraulic oil on the steering rack. This article will explore in depth the causes of hydraulic oil deterioration, its potential harm to the steering rack, and how to prevent and deal with these problems.

What are the basic functions of hydraulic oil?

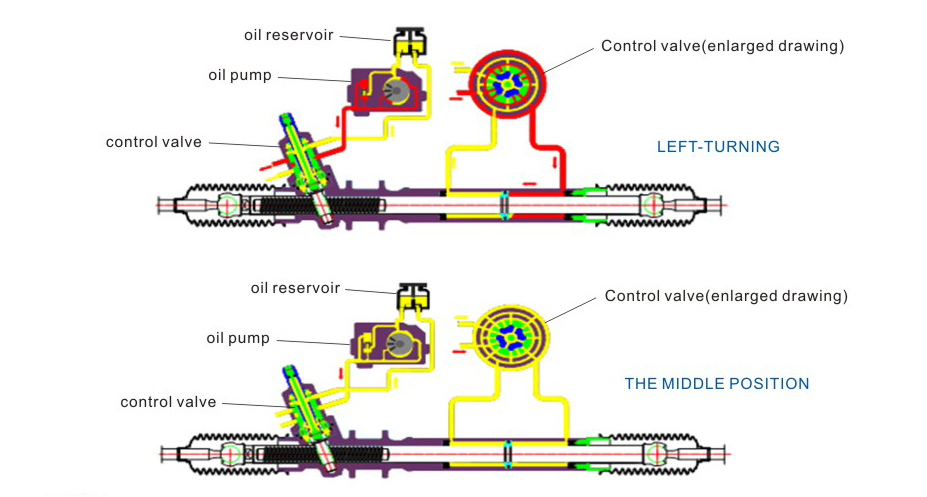

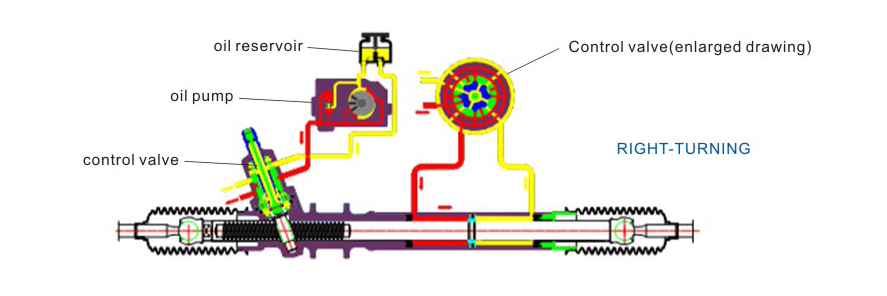

Hydraulic oil is the working medium of the hydraulic steering system, mainly used to transmit force and motion, and also has functions such as lubrication, cooling, and corrosion protection. In the steering system, hydraulic oil is pressurized by the hydraulic pump and transferred to the steering rack or steering valve to assist the driver in achieving easy steering.

Lubrication function

Hydraulic oil can reduce friction between hydraulic pumps, gears and other mechanical parts to prevent excessive wear. The quality of lubrication performance directly affects the life and reliability of the steering system.

Cooling function

During the operation of the steering rack, mechanical parts will generate heat due to friction. When the hydraulic oil flows, it can take away some of the heat to prevent the system from overheating, thereby maintaining a normal operating temperature.

Anti-corrosion function

Hydraulic oil can also form a protective film on the surface of the machine to prevent moisture and impurities in the air from corroding metal parts. This function is particularly important for maintaining the long-term stability of the steering rack.

Why does hydraulic oil deteriorate?

Hydraulic oil may deteriorate due to various reasons during long-term use. This deterioration will weaken the above functions of hydraulic oil, thereby causing adverse effects on the hydraulic steering rack.

Oxidation caused by high temperature

Hydraulic oil is prone to oxidation reaction when used for a long time in a high temperature environment. The color of oxidized hydraulic oil will become darker, the viscosity will increase, and acidic substances will be formed. These acidic substances will further accelerate the corrosion of metal parts and the deterioration of hydraulic oil. Oxidation reactions will also produce some solid impurities, such as sludge and carbon deposits, which will block the pipes and filters in the hydraulic steering rack and affect the normal circulation of hydraulic oil.

Moisture contamination

The hydraulic steering rack is not completely sealed, and moisture in the air may enter the hydraulic oil through the pipe joints or the vents of the oil tank. The mixing of water will reduce the lubrication effect of hydraulic oil, accelerate the oxidation of oil, and cause emulsions to form in the oil. These emulsions will not only reduce the transmission efficiency of hydraulic oil, but may also freeze at low temperatures, causing blockage and failure of hydraulic steering rack.

Impurity intrusion

During the operation of hydraulic steering rack, wear of seals, aging of pipelines, and dust and impurities in the external environment may enter the hydraulic oil. These solid impurities will cause contamination of hydraulic oil, increase wear of hydraulic pumps and valves, and may cause system blockage. Impurities in hydraulic oil not only affect the lubrication effect, but may also scratch the precision parts of hydraulic steering rack, resulting in system performance degradation.

Additive failure

Hydraulic oil is usually added with chemical additives such as antioxidants, anti-wear agents, and rust inhibitors to improve the performance of oil. However, over time, these additives will gradually fail, thereby reducing the protective performance of hydraulic oil. When the additives fail, the lubrication, anti-corrosion and cooling functions of hydraulic oil will be greatly reduced, increasing the risk of hydraulic steering rack failure.

What effect does deteriorated hydraulic oil have on the steering system?

Deteriorated hydraulic oil can cause many kinds of harm to the hydraulic steering system, and its impact is often multifaceted, which may cause the performance of the steering rack to deteriorate or even cause serious failures.

Steering power reduction or failure

When the hydraulic oil deteriorates, the viscosity increases and the fluidity deteriorates, which will cause the working efficiency of the hydraulic pump to decrease, thereby weakening the hydraulic steering rack power. The driver will feel that the steering becomes heavy, especially when driving at low speeds, and the steering operation may require more effort. If the hydraulic oil is seriously deteriorated, it may even cause the steering power to fail completely, posing a great hidden danger to driving safety.

Increased system noise

Impurities and bubbles in the hydraulic oil can cause abnormal noise when the hydraulic pump and valve are working. These noises usually appear as sharp buzzing or creaking sounds, especially when turning the steering wheel. This noise not only affects driving comfort, but also indicates that there may be problems inside the hydraulic steering rack, which needs to be checked and handled in time.

Insufficient lubrication causes component wear

When the lubrication function of the hydraulic oil deteriorates, the friction between the hydraulic pump, gears and other mechanical parts increases, which is easy to cause excessive wear. The worn metal particles will further contaminate the hydraulic oil, forming a vicious cycle. In the long run, the life of the hydraulic steering rack will be greatly shortened, and may even lead to the early scrapping of key components.

System overheating and efficiency reduction

The deteriorated hydraulic oil has increased resistance when flowing, resulting in an increase in the workload of the hydraulic pump and an increase in the system temperature. High temperature not only accelerates the further oxidation of the hydraulic oil, but also may cause the seals in the system to age, deform, or even fail, further affecting the sealing and working efficiency of the hydraulic steering rack. The decline in system efficiency will directly affect the steering accuracy and sensitivity, and increase the difficulty of vehicle control.

System leakage and seal failure

Deteriorated hydraulic oil contains acidic substances and solid particles, which will cause corrosion and wear to the seals in the hydraulic system, increasing the risk of system leakage. Hydraulic oil leakage will not only lead to a weakening of the steering rack assist, but may also pollute the environment and even cause safety hazards such as fire. In addition, after the seal fails, the loss of hydraulic oil will accelerate, and the hydraulic oil needs to be frequently replenished, which undoubtedly increases the maintenance cost of the vehicle.

How to prevent hydraulic oil from deteriorating?

Hydraulic oil should be replaced regularly as recommended by the car manufacturer, usually every two years or after a certain mileage. Timely replacement of hydraulic oil can prevent the oil from oxidizing and deteriorating due to long-term use, and it can also remove impurities in the system to keep the hydraulic steering rack clean and functioning properly.

Secondly, regularly check the seals, pipes and joints of the hydraulic steering rack to ensure that there are no leaks or looseness. Timely replacement of aging or damaged seals prevents moisture and impurities from entering the hydraulic steering rack to maintain the purity of the hydraulic oil. In addition, it is very important to choose high-quality hydraulic oil that meets the vehicle's specifications. High-quality hydraulic oil usually contains better antioxidants and anti-wear agents, which can maintain stable performance for a longer period of time. In addition, avoid mixing different brands or types of hydraulic oil to prevent chemical reactions between oils from causing performance degradation.

When replacing hydraulic oil, it is best to clean the filter and pipes of the hydraulic system at the same time to remove carbon deposits and sludge in the system. This can reduce the resistance to the hydraulic oil flowing in the system, reduce the risk of system overheating, and ensure that the hydraulic oil can fully perform its role.

Guangdong Diamond Auto Parts Co., Ltd., also known as DKM Company, has been a trusted name in the power steering rack industry since 1996. With advanced technology and a skilled workforce, we specialize in producing gear-and-rack steering systems for vehicles across Europe, America, and Asia. Our products are compatible with leading brands like Toyota, Honda, Hyundai, and Mitsubishi, ensuring reliability and performance. We provide competitive wholesale pricing, customized solutions, and promotional discounts for large orders!