What Is A Rack and Pinion? What Are the Symptoms of a Malfunction?

In the steering system of a car, racks and pinions are one of the most critical components. They directly affect the vehicle's handling and driving safety. Understanding the working principle of racks and pinions and the possible symptoms of their failure is crucial to the normal use and safe maintenance of the vehicle.

This article will delve into the basic concepts, working principles, and typical symptoms of racks and pinions when they fail.

What Is A Rack and Pinion?

Racks and pinions are common components in mechanical transmission systems and are widely used in various mechanical equipment and automotive steering systems. To understand the role of racks and pinions, you first need to understand their basic structure and working principle.

What Is the Basic Structure of a Rack and Pinion?

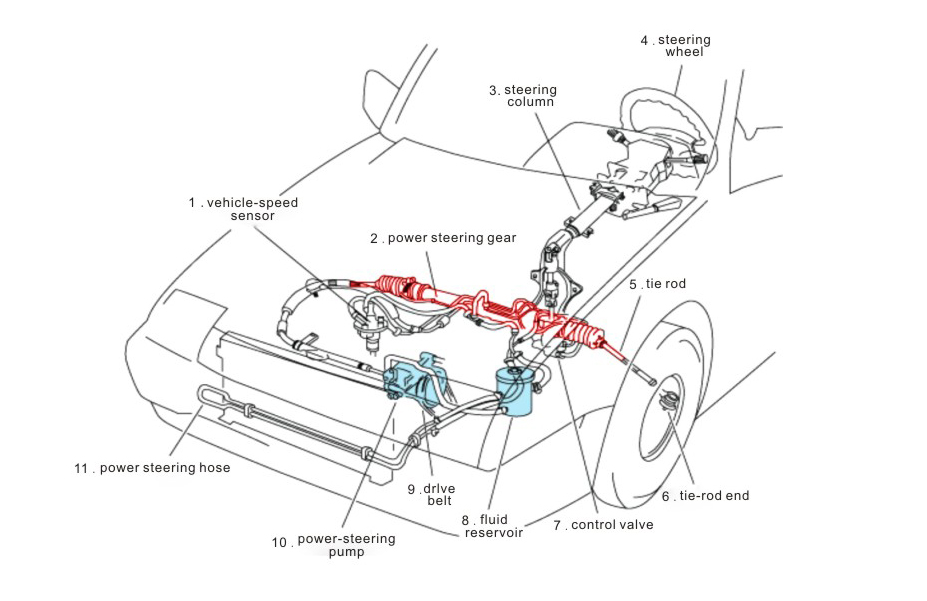

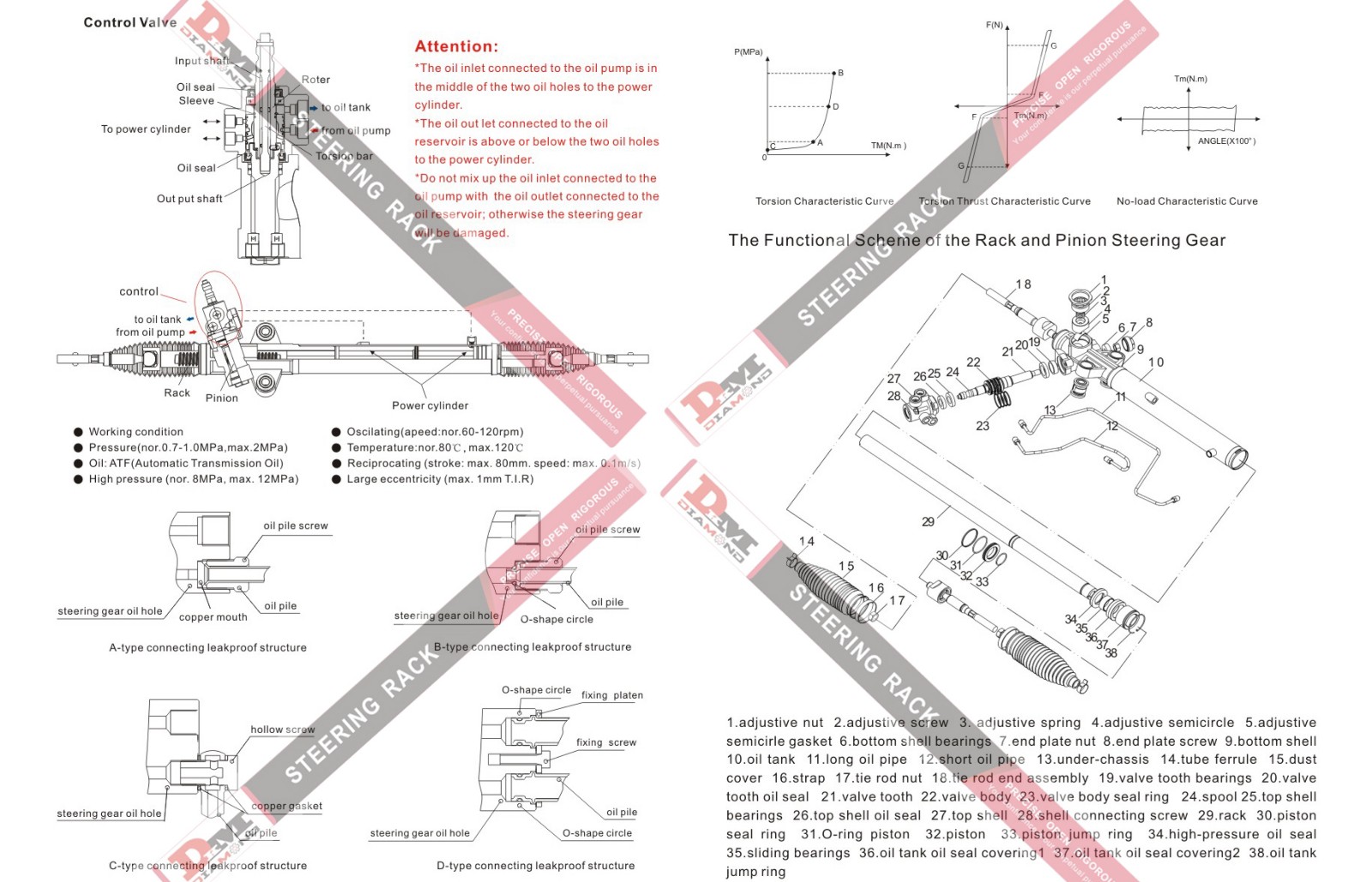

A rack and pinion system consists of two main components: a pinion and a rack.

● A pinion is a circular gear that is usually connected to the steering wheel. When the driver turns the steering wheel, the pinion rotates.

● A rack is a long rack with teeth that mesh with the teeth of the pinion. The rotational motion of the gear is converted into linear motion by the rack, which drives the vehicle's wheels to turn left or right.

In simple terms, the gear is responsible for converting the driver's rotational motion into the linear motion of the rack, a process that makes it possible for the wheels to turn.

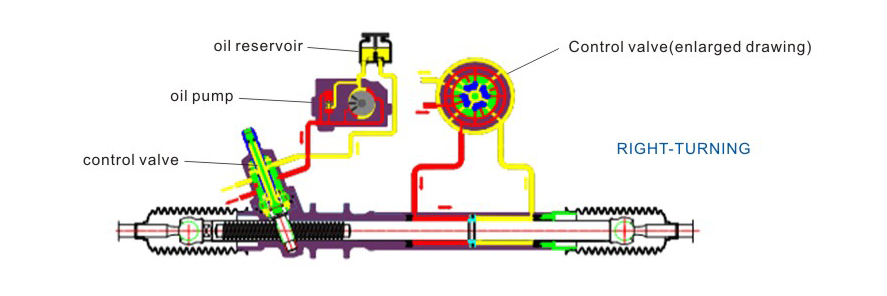

How Does a Rack and Pinion Work?

The working principle of a rack and pinion system is relatively simple. When the driver turns the steering wheel, the gear starts to rotate and meshes with the teeth on the rack. The rotational motion of the gear is converted into linear motion by the rack, and this motion is transmitted to the wheel through the connecting rod, causing the wheel to turn.

The main advantages of this system are its simple structure, fast response and relatively low cost. Due to the design of the rack and pinion, the driver can get direct road feel feedback, which plays a positive role in improving the driver's confidence and accuracy in vehicle control.

What Is the Role of a Rack and Pinion System?

The main role of a rack and pinion system in a car is to realize the steering function of the vehicle. It enables the driver to accurately control the direction of the vehicle by converting the rotational motion of the steering wheel into the steering action of the wheels.

Provide Precise Steering Control

Rack and pinion systems provide relatively direct steering control due to their simple structure. The system is designed so that the driver can feel the vehicle's response immediately when turning the steering wheel, so in an emergency, the driver can steer quickly and accurately.

Enhance the Driver's Road Feel

Rack and pinion systems can directly transmit feedback about road conditions to the driver. For example, when the wheels encounter uneven roads or obstacles, the driver can clearly feel these changes through the steering wheel. This road feel feedback can help the driver better judge road conditions and make corresponding driving decisions.

Improve the Reliability and Durability of the System

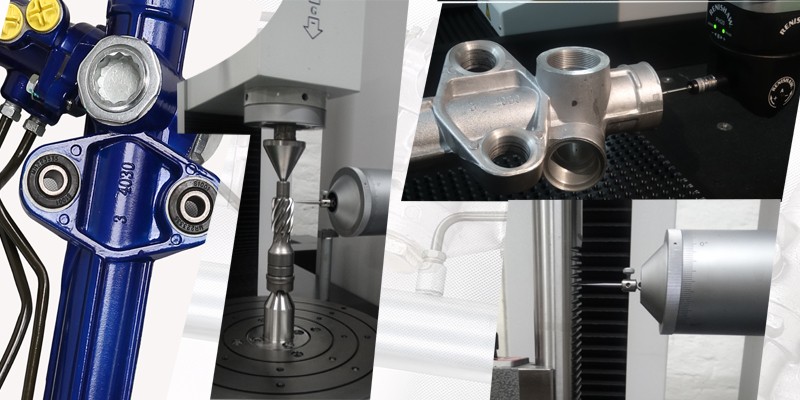

Rack and pinion systems are widely used in various vehicles due to the stability of their mechanical structure. The system has shown high reliability and durability in long-term use and is relatively easy to maintain and repair.

What Are the Common Faults and Symptoms of Rack and Pinion Systems?

Although rack and pinion systems are widely praised for their stability, they can also experience various faults over time and with increased frequency of use. These faults may affect the vehicle's handling and even threaten driving safety. Therefore, it is particularly important to identify the fault symptoms of rack and pinion systems.

Heavy or Sluggish Steering

One of the most common symptoms of a rack and pinion system failure is heavy or sluggish steering. This often happens when there is a problem with the hydraulic power steering system. For example, a failed hydraulic pump or hydraulic fluid leak can cause the system to not provide enough power assistance, requiring more force to turn the steering wheel.

In addition, wear, rust or dirt on the surface of the gear or rack can also increase the mechanical friction of the system, making steering difficult. If the driver feels effort when turning the steering wheel or the steering wheel is unresponsive, the rack and pinion system should be checked immediately.

Abnormal Noise

When a rack and pinion system fails, abnormal noise is also a common symptom. Common types of noise include:

● Squeaking: Usually caused by a lack of lubrication between the gears or racks. The friction between metal surfaces without lubrication will produce a high-frequency squeaking sound.

● Clicking: When the teeth on the gear or rack are broken or damaged, the gears are not fully engaged and a clicking sound may occur. This sound is usually more obvious when the steering wheel is turned to the extreme position.

● Clicking noise: A clicking noise may occur when a rack or pinion is loose or a component in the system is damaged. This sound is often accompanied by a shaking or unstable steering wheel.

If you hear any unusual noises while driving, especially those related to steering operations, you should check and repair them immediately.

Excessive Steering Wheel Free Play

The free play of the steering wheel refers to the idle distance before the wheels start to turn when the steering wheel is turned. Under normal circumstances, the free play should be within a certain range (usually 2-3 degrees). However, when there is a problem with the rack and pinion system, the free play may become too large.

Causes of excessive free play may include:

● Gear wear: Over time, the teeth of the gear may wear or loosen, resulting in a loose mesh between the rack and the pinion, which increases the free play.

● Loose rack: Loose rack fixtures or connecting rods may also cause increased free play. This situation will make the driver feel that the steering wheel is somewhat loose and the steering response is not as sensitive as before.

Excessive free travel can affect the vehicle's handling, especially at high speeds, and may cause steering instability, so it should be checked and repaired in a timely manner.

Steering Wheel is Difficult to Return to Center

Under normal circumstances, when the driver completes the steering operation, the steering wheel should be able to automatically return to the state of straight driving. However, when the rack and pinion system fails, the steering wheel may become difficult or slow to return to center.

Possible causes of this situation include:

● Wear of the rack or pinion: If the teeth on the rack or pinion wear unevenly, it may cause increased friction in the steering system, which will prevent the normal return of the steering wheel.

● Hydraulic system failure: In a hydraulic power steering system, insufficient hydraulic oil pressure or a hydraulic pump failure can also affect the steering wheel's ability to return to center.

If the driver finds that the steering wheel cannot return smoothly after turning, or needs to manually adjust the steering wheel to return to straight driving, the rack and pinion system should be checked as soon as possible.

Abnormal Vehicle Driving Trajectory

When the rack and pinion system fails, the vehicle's driving trajectory may be abnormal. For example, the vehicle may deviate from the straight driving trajectory even if the steering wheel is in the neutral position.

Possible causes of this include:

● Poor rack-pinion meshing: If the meshing between the rack and the pinion is uneven or the rack is bent, it may cause the wheel angle to be inconsistent, causing the vehicle's driving trajectory to deviate.

● Suspension system problems: Although the problem may originate from the suspension system, a failure in the rack and pinion system may also cause the vehicle's driving trajectory to be unstable.

If the driver finds that the vehicle is difficult to keep driving in a straight line during driving, he should check it immediately. This not only affects driving comfort, but may also increase the risk of accidents.

How to Prevent Rack and Pinion System Failures?

The meshing between the rack and the pinion relies on good lubrication to reduce friction and wear. Therefore, it is crucial to regularly check the lubrication condition of the steering system. Ensuring that there is enough lubricant in the system and that the lubricant is kept clean can effectively reduce the wear between the gear and the rack. Especially after experiencing extreme weather (such as cold or hot weather), the performance of the lubricant may decrease. It is recommended to check and add lubricant more frequently in this case.

For vehicles equipped with hydraulic power steering systems, it is equally important to check and replace the hydraulic oil. The hydraulic oil not only plays a lubricating role in the system, but is also responsible for providing enough pressure to assist in steering operations. Check the hydraulic oil level and condition regularly to ensure there is no leakage or contamination. If the hydraulic oil is found to be deteriorating or the level is reduced, it should be replaced or replenished immediately.

Secondly, all components in the rack and pinion system (including racks, pinions, connecting rods, suspension components, etc.) should be kept tight. If any of these components are loose, it may cause the system to work unstable or have excessive free travel. Check the tightness of these components regularly to ensure that they are all firmly fixed in place.

In addition, some bad driving habits will accelerate the wear of the rack and pinion system. For example, slamming the steering wheel when stationary or frequent sharp turns will put additional pressure on the system, thereby accelerating the wear of components. Developing good driving habits and avoiding excessive force on the steering wheel can effectively extend the service life of the rack and pinion system.

When any of the above fault symptoms are found in the rack and pinion system, it should be inspected and repaired immediately. If some parts are severely worn or damaged, they should be replaced in time. Delaying repairs may cause the problem to deteriorate further and even affect the overall handling and driving safety of the vehicle.