What noises does a faulty hydraulic power steering rack make?

Hydraulic power steering is a vital component of modern cars, providing assistance to make it easier for drivers to turn the steering wheel. However, when key components in the hydraulic power steering system, such as the steering rack, fail, they are often accompanied by abnormal noises. These noises are not only disturbing, but may also indicate potential problems with the steering system. Identifying and resolving these problems in a timely manner can avoid more serious mechanical failures and ensure driving safety.

This article will delve into the various types of noises that may be made when the hydraulic power steering rack fails, analyze the causes of these noises, and how car owners should deal with these situations.

What are the basic principles of hydraulic power steering systems?

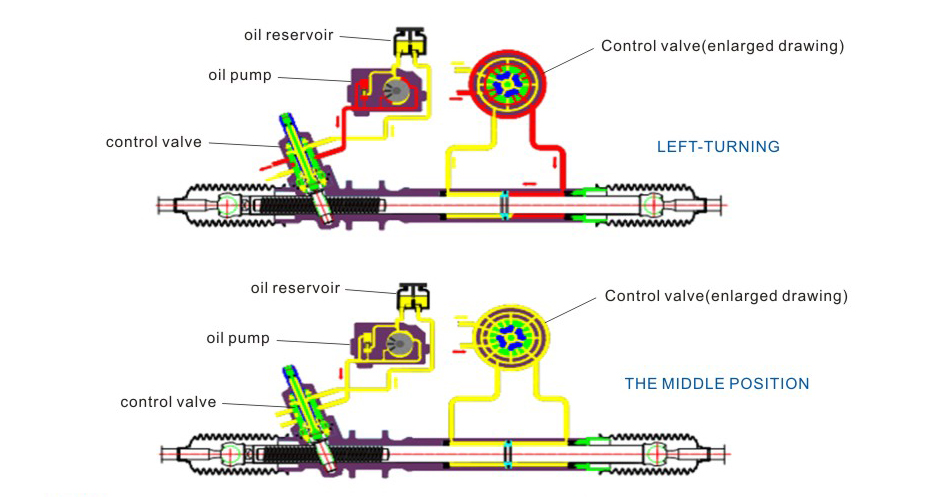

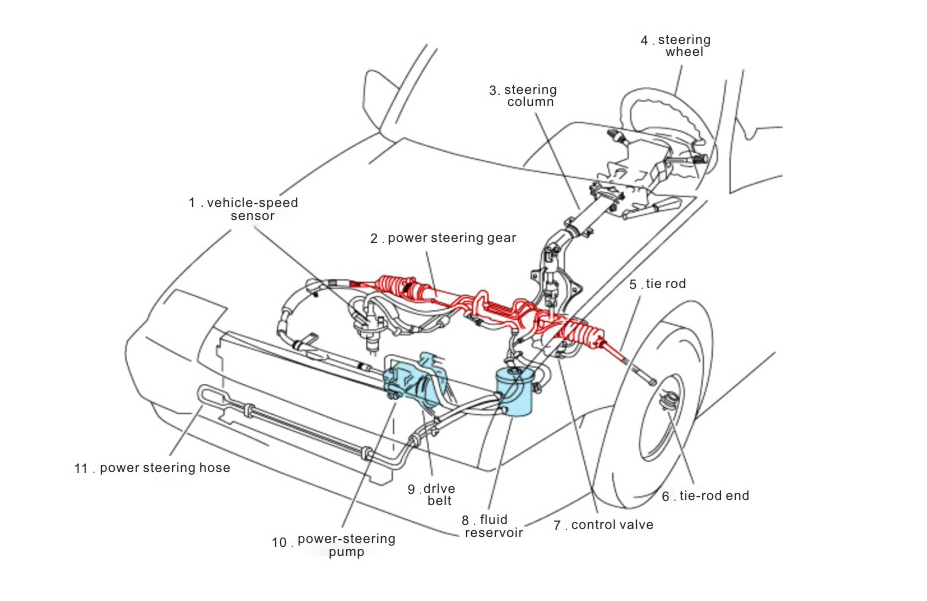

Before discussing noises in depth, it is necessary to understand the basic working principles of hydraulic power steering systems. Hydraulic power steering systems (HPS) rely on the pressure of hydraulic oil to provide steering assistance. The system mainly consists of hydraulic pumps, hydraulic lines, steering racks, hydraulic cylinders and other related components. When the driver turns the steering wheel, the hydraulic pump generates hydraulic oil pressure, which is transmitted to the hydraulic cylinder in the steering rack through the hydraulic pipeline, so that the steering rack moves and provides power.

If any component in the hydraulic power steering system fails, it will affect the normal operation of the entire system and may produce different types of noise. These noises are usually "help signals" issued by the system, prompting the owner to check and repair in time.

What noises does a faulty hydraulic power steering rack make?

A faulty hydraulic power steering rack may make noises such as:

1. Whining Noise

2. Clunking or Knocking Noise

3. Squealing or Screeching Noise

4. Hissing Noise

5. Grinding Noise

When a hydraulic power steering rack fails, it usually makes several common noises. Understanding the characteristics of these noises will help car owners identify the specific cause of the failure and take appropriate measures. Here are some typical noises and their possible causes:

1. Whining Noise

Whining noise is one of the most common noises in hydraulic power steering systems, and it usually occurs when turning the steering wheel. If the owner hears a humming noise similar to that of an electric motor when turning the steering wheel, it is likely related to the hydraulic power steering pump, not necessarily a problem with the steering rack itself.

Possible causes:

● Insufficient hydraulic oil: If the hydraulic oil level is below the normal range, the hydraulic pump may inhale air when working, causing bubbles in the system. When these bubbles flow in the hydraulic pipeline, a humming noise will be generated. This situation will not only affect the effect of the steering assist, but may also accelerate the wear of the hydraulic pump.

● Hydraulic oil contamination: Hydraulic oil containing impurities or deterioration will also cause the hydraulic pump to hum when working. Contaminated hydraulic oil will increase the friction resistance in the system and affect the normal operation of the hydraulic pump and other components.

2. Clunking or Knocking Noise

Clunking or knocking noises usually occur when the vehicle is turning or driving on bumpy roads. If the owner hears this sound when turning the steering wheel or passing through uneven roads, it may mean that there is a problem inside the steering rack.

Possible causes:

● Loose steering rack: If the steering rack or its fixing parts are loose, the rack may move slightly when the vehicle is driving or turning, causing metal-to-metal collisions, resulting in a clicking sound.

● Internal wear or breakage: If the mechanical parts inside the steering rack are worn or broken, they may make a knocking sound when turning the steering wheel. This situation may require the steering rack to be disassembled for detailed inspection and repair.

3. Squealing or Screeching Noise

Squeaking or screaming noises usually occur when the vehicle is turning at low speed or when the steering wheel is fully turned. If the owner hears this harsh sound when turning, it may be related to multiple parts of the hydraulic system.

Possible causes:

● Loose or worn belt: The hydraulic power steering pump is usually connected to the engine by a belt. If the belt is loose or worn, a squeaking sound will be generated when working. As the belt wears more, this noise will become more frequent and obvious.

● Hydraulic oil is too dirty or too old: As mentioned above, if the hydraulic oil is too dirty or has lost its lubricating effect, it may also cause the hydraulic pump to squeak when working. Especially in low temperature environments, poor quality hydraulic oil will make the pump more difficult to operate, resulting in sharp noises.

4. Hissing Noise

Hissing noise is usually produced when there is a hydraulic oil leak in the hydraulic system. This sound is similar to the sound of gas slowly leaking out of a balloon, usually accompanied by a gradual drop in the hydraulic oil level.

Possible causes:

● Hydraulic line leakage: A rupture in the hydraulic line or a loose joint may cause hydraulic oil leakage, resulting in a hissing sound. This sound is usually most obvious in the engine compartment. The owner should check the hydraulic oil level in time and find possible leaks.

● Damaged seals: If the seals in the hydraulic power steering system are damaged, it may cause the pressure in the system to drop and hydraulic oil to leak. The hissing sound is usually an early symptom of seal damage, and the sound will become more obvious as the leakage intensifies.

5. Grinding Noise

A squeaking noise is a worrying noise that usually indicates that the metal parts in the steering system are experiencing severe wear or contact. If the owner hears this sound when turning the steering wheel, he should stop driving immediately and check the steering system.

Possible causes:

● Insufficient hydraulic oil: When the hydraulic oil is seriously insufficient, the metal parts in the steering rack may directly contact and wear, producing a squeaking noise. This situation will not only cause the loss of steering power, but may also cause irreversible damage to the steering system.

● Mechanical failure in the steering rack or pump: If there are damaged or severely worn parts inside the steering rack or hydraulic pump, a squeaking sound of metal friction may be emitted. This usually means that the lubrication inside the steering system has failed, and the direct friction between the parts is accelerating the damage of the system.

How to deal with the noise emitted by the hydraulic power steering rack?

First, check the hydraulic oil in time. The level and quality of the hydraulic oil are the basis for the normal operation of the hydraulic power steering system. Car owners should regularly check whether the hydraulic oil level is within the normal range and pay attention to the color and smell of the hydraulic oil. If the hydraulic oil level is found to be low or deteriorated, it should be replenished or replaced in time. At the same time, the hydraulic pipeline should also be checked for signs of leakage and repaired in time.

If the noise is found to be caused by wear or damage of certain parts, these parts should be replaced as soon as possible. For example, loose or worn belts can cause creaking noises, and it is necessary to adjust the tension of the belts or replace new belts. For severely worn steering racks or pump internal parts, it is recommended to ask professional technicians to check and replace them.

In addition, in order to prevent the generation of noise and damage to the system, car owners should regularly perform steering system maintenance, including replacement of hydraulic oil, inspection of seals, and lubrication of steering racks. Regular maintenance can not only extend the service life of the system, but also improve driving comfort and safety. If the owner cannot determine the source or cause of the noise, it is recommended to consult a professional technician as soon as possible. Technicians can accurately diagnose problems and propose solutions through professional equipment and experience to avoid further deterioration of the problem.