Why do hydraulic oil contamination and steering pump degradation damage the steering rack?

In modern cars, the hydraulic power steering system is an important part of ensuring smooth vehicle control, and the core components of this system include hydraulic oil, steering pump and steering rack. The cleanliness of the hydraulic oil and the performance of the steering pump are directly related to the effective operation of the entire power steering system. Hydraulic oil contamination and steering pump degradation not only reduce the steering accuracy, but may also cause irreversible damage to key components, especially the steering rack.

This article will explore why hydraulic oil contamination and steering pump degradation damage the steering rack and the relevant mechanisms in this process.

How does the hydraulic power steering system work?

To understand why hydraulic oil contamination and steering pump degradation can cause damage to the steering rack, you first need to understand the basic working principle of the hydraulic power steering system.

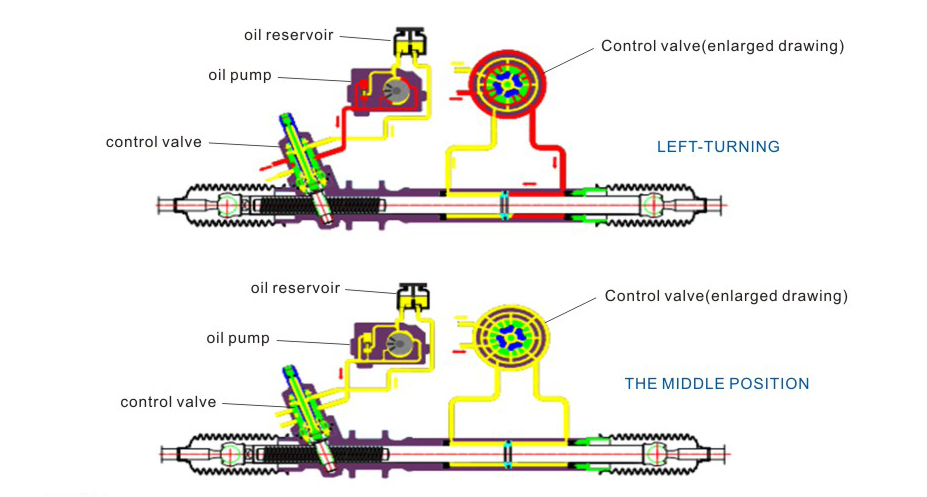

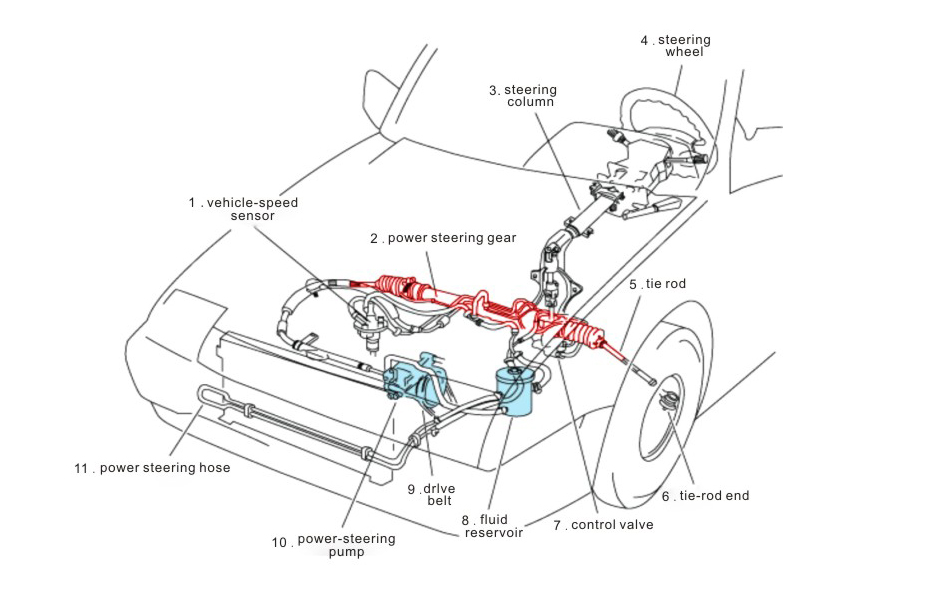

The hydraulic power steering system helps the driver control the steering wheel easily by transmitting pressure through hydraulic oil. During the steering process, the steering pump is responsible for pressurizing the hydraulic oil and sending the oil into the working chamber in the steering rack to generate power, thereby reducing the driver's physical input when steering. Hydraulic oil plays a key role in the entire system, and its lubrication and cooling effects directly affect the normal operation of the steering rack.

The main components include:

● Hydraulic oil: as a medium for transmitting pressure, ensuring smooth operation of the system.

● Steering pump: builds the pressure required by the system by pumping hydraulic oil.

● Steering rack and pinion: transmits steering force to steer the front wheels.

What effect does hydraulic oil contamination have on the steering rack?

Particle contamination

The cleanliness of hydraulic oil is one of the important factors affecting the life of the hydraulic power steering system. Normally, hydraulic oil should be kept clean to ensure that it circulates smoothly in the system and fully exerts its lubrication and anti-corrosion effects. However, when hydraulic oil is contaminated by external contaminants such as dust, metal particles, rust, etc., these tiny particles will enter every component of the steering system with the hydraulic oil, especially the steering rack and pinion.

● Increased friction: Particles in the contaminants increase the friction between the steering rack and the pinion in the hydraulic oil. Over time, the particles will wear the surface of the rack like sandpaper, causing it to gradually lose its smooth operability. Especially at the meshing point between the rack and the pinion, continuous friction can cause material fatigue and produce wear marks.

● Wear: When particles enter the contact point between the rack and the pinion, they may accelerate the mechanical wear between the two, thereby reducing their precision and causing a loose feeling or instability during steering. This wear will not only affect the handling of the steering system, but will also further deteriorate the life of the entire system.

Hydraulic oil oxidation and deterioration

Long-term exposure to high temperature and high pressure environments will cause the hydraulic oil to gradually oxidize and decompose, and the byproducts may include acidic substances and sediments. When the hydraulic oil deteriorates, its lubrication performance decreases significantly and its corrosiveness increases. These chemical byproducts will also affect the steering rack.

● Lubrication failure: When the hydraulic oil deteriorates, its viscosity and lubrication performance decrease, and the steering rack may lack sufficient lubrication protection during operation, thereby increasing the friction between the metal parts. The surfaces of the rack and the gear will directly contact due to lack of lubrication, resulting in rapid wear.

● Corrosion problem: Oxidized hydraulic oil may produce corrosive substances, which will aggravate the corrosion of rack and pinion, especially if the rack is made of lower quality metal materials, the corrosion rate will be faster, affecting the normal operation of the entire steering system.

What effect does the decline in steering pump performance have on the steering rack?

Insufficient pressure

The steering pump is responsible for providing sufficient pressure to the entire hydraulic system to ensure that the hydraulic oil can effectively push the steering rack. However, when the performance of the steering pump declines, the flow rate and pressure of the hydraulic oil will be affected.

● Weakened power assist: When the steering pump cannot provide sufficient pressure, the power assist effect of the steering system will be greatly reduced, and the driver will need to apply more force to complete the steering operation. Excessive operating force will be directly applied to the steering rack and pinion, accelerating their wear.

● Unstable pressure fluctuations: If the output pressure of the steering pump fluctuates unstably, it will cause the hydraulic oil flow to be high and low. This unstable hydraulic environment will produce uneven force on the rack and pinion, resulting in different pressures on the rack in different operations, thereby accelerating its loss.

Internal wear of the steering pump

The blades or gears inside the steering pump may wear out due to fatigue or insufficient lubrication during long-term use. When the steering pump itself is worn, the metal debris inside it will enter the system with the hydraulic oil and become a contaminant in the hydraulic oil.

● Impact of metal debris: Once the metal debris generated by the steering pump enters the steering rack and gear, it will aggravate the wear of these parts. Metal debris is often more destructive than ordinary contaminant particles because they are harder and sharper, which may cause faster mechanical wear.

● Pump efficiency decline and rack response sluggish: When the steering pump efficiency declines due to internal wear, the response speed of the steering rack will become slow, which not only affects the driving experience, but also may cause the rack to be subjected to excessive mechanical stress under high load conditions, further accelerating its damage.

How do hydraulic oil contamination and steering pump damage accelerate rack damage?

Hydraulic oil contamination and steering pump performance decline usually do not exist independently. They often interact with each other and accelerate the damage of the steering rack.

Pressure imbalance and contaminant accumulation

When the steering pump cannot provide stable pressure due to performance decline, the flow rate and pressure of the hydraulic oil will fluctuate. This not only affects the normal operation of the hydraulic system, but also causes contaminants to accumulate in low flow rate areas. When these contaminants accumulate at the contact point of the steering rack and gear, the rate of local wear will be significantly accelerated.

Lubrication failure and increased mechanical stress

When the hydraulic oil is seriously contaminated or the steering pump is damaged, the lubrication capacity in the hydraulic system will be significantly reduced. At this time, the metal contact between the rack and the gear will increase, and the mechanical parts that lack lubrication will be subjected to greater stress during operation. Over time, cracks, scratches, and even breaks may appear on the surface of the rack and gear, eventually leading to system failure.

The dual effects of corrosion and wear

The deterioration and contamination of the hydraulic oil will accelerate the corrosion of the steering rack, while the metal debris and pressure fluctuations generated by the deterioration of the steering pump performance will further aggravate the wear of the rack. The dual effects of corrosion and wear will cause a significant decrease in the operability of the steering system, and eventually lead to structural damage to the rack.

With a strong focus on quality and innovation, DKM is a leading manufacturer of power steering systems for the automotive industry. Established in 1996, our products serve a variety of brands from Europe, the USA, and Asia. Our advanced production facilities, equipped with over 280 CNC machines, ensure reliable, low-cost solutions for bulk buyers. DKM is committed to providing exceptional customer service, with wholesale prices and customizable options to suit your needs. Contact us today for a quote and explore our extensive catalog of steering systems.