48001-3RH1A Sylphy 2012 RHD Manual steering rack

- DKM

- China

- 15-75days

- 300000pcs per year

- DKM 58.07.04R

A manual steering rack is a part of a vehicle's steering system that does not rely on hydraulic power from the engine to change the vehicle's direction. In a manual steering system, the driver directly manipulates the steering rack through the steering wheel. When the driver turns the steering wheel, a mechanical connection between the steering rack and a gear (usually a pinion) transfers the steering wheel's rotational force to the wheels, causing them to turn.

The Sylphy steering rack system is generally simpler, lighter, and more cost-effective to maintain. However, it may require more effort from the driver, especially during situations that demand greater steering input, such as parking or maneuvering at low speeds.

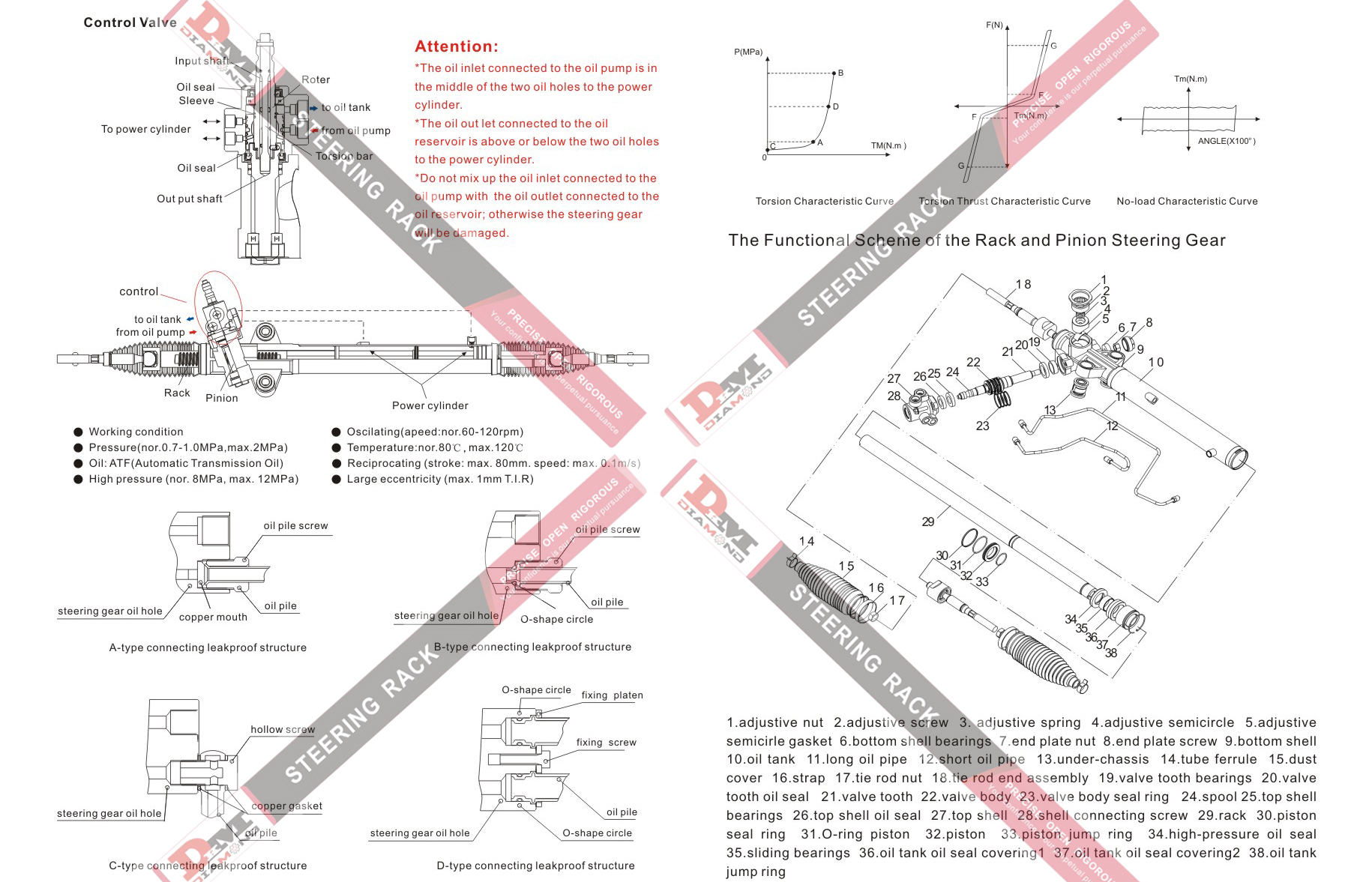

The Structure Principle of Power Steering Gear

This is a rack and pinion steering gear specifically for the Sylphy model, identified by the part number 48001-3RH1A. The back of the pinion is equipped with an adjustable semicircular component. This component is pressed against the rack by a spring, ensuring that the rack engages with the pinion under optimal pressure. The clearance in the steering mechanism is fine-tuned using this adjustable semicircle and the spring mechanism.

The Traits of the Rack and Pinion Steering Gear

Rack and pinion steering gear has a simple structure,easy design procedure,high transmission efficiency.It is produced by the completely sealed devices,so it is reliable.In foreign countries,it is widely used many years ago.But due to the low transmission ratio,the use of this steering gear is restricted.At present it is more used in mini cars.In the rack and pinion steering gear,there is a cylindrical gear in the end of steering shaft.It meshes with the rackin hull which is fixed in the car frame.The rack is linked by two ball joints and two tie rods. It directly drives the tie rods to move to make the car rotate.

If the parts in the rack and pinion steering gear wear and the gap appears,the force of the spring will push it to the platen,so as to keep it mesh with the rack,so that the steering wheel is in an appropriate space and raise the manipulation of sensitivity.

The Advantages of Rack and Pinion Steering Gear

The manual steering rack, lacking components like a pitman arm and rocker unit, is straightforward in design, easy to install, and convenient to manufacture. Its simplicity and reliability contribute to a long operational life, making it a popular choice for use in light and compact cars.

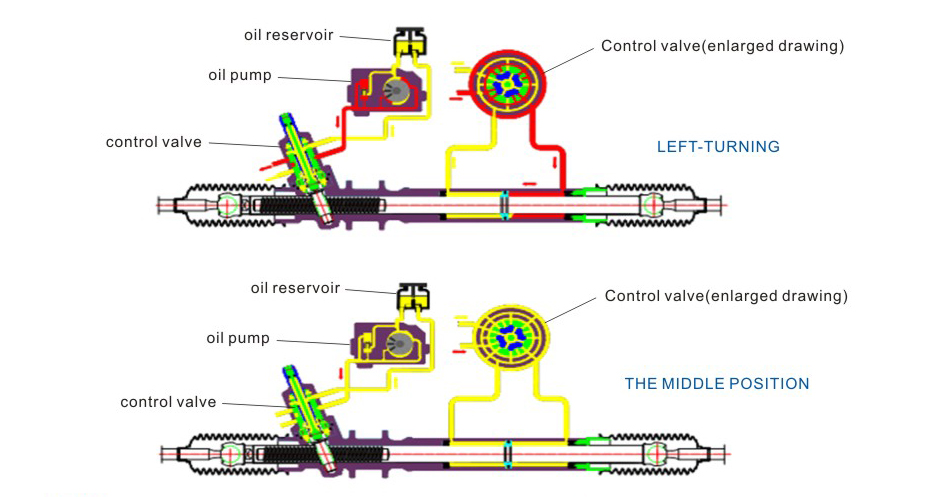

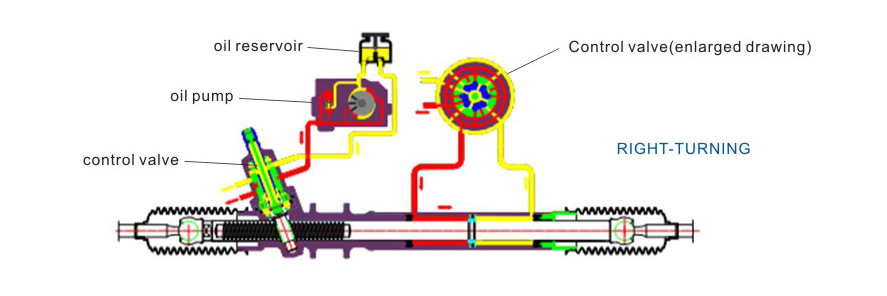

The Functional Scheme of the Power Steering System

The Correct Usage and Maintenance of the Powersteering Gear

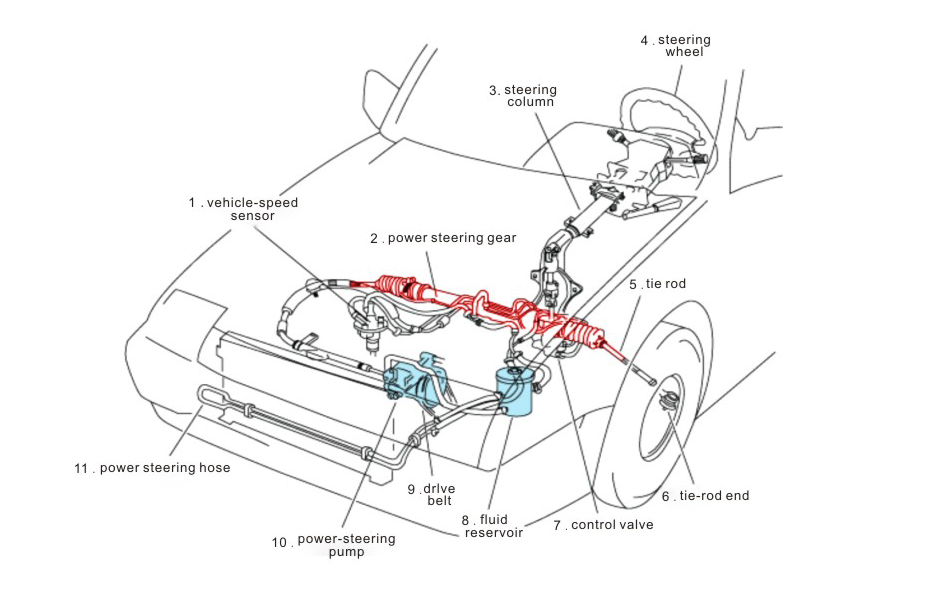

Power Steering Gear Installation Scheme

Common Faults and Solutions

Steering system of any fault will affect the traffic safety and may cause failure. So the steering system must often be checked.

Problem Cause Solution

Problem of rotatingThe tire pressure is insufficient,engine works unstably To charge the tire and adjustthe engine The casteris too large Check the wheel alignment Cardan joint wear Change the cardan joint Ball-and-socket joint wear Change the joint The steering column gets stuck Check the steering column The piston wear and the rotaryvalve gets stuck Repair the steering gear Too low oil pressure Change the oil pump Overloading Load shedding Steering pump Check the steering pump control valve and clean the entire steering systemor change the oil cup in necessary. The belt or the pump gets loose Adjust the belt according to the regulations There is air in the steering gear Discharge the air The bolts in the oil pipe gets loose, causing oil leakage Check the oil pipe and tighten the bolts

Problem with rotating to one directionToo low pressure in the tire To charge the tire One side leakage Repair the steering gear The rotary valve is not in the middle position Can not produce pressure in both left and right sides Change the sealing element

Problem with rotatingThere is air in the connection of the outlet, the inlet, the oilpump and the engine Tighter the joint or changethe sealing element Too low oil pump flow Change the oil pump

Steering wheel shakesThe steering wheel and steering shaft gets loose Steering transmission devices connecting parts Tighten the loose Front wheel bearing wear Change the front wheel bearing Principle axis wear Change the axis Ball-and-socket joint wear Check the ball-and-socket joint Ball joint wear or tie rod wear Change the ball joint or tie rod The wheel gear wear Repair the wheel gear

Too high temperatureToo large oil pump flow Change the oil pump Not free oil flow Change the oil pipe Turning to the limit takes more than 5 seconds Avoid turning to the limit

Unstable steeringThe parts in steering system gets loose or is worn Tighten or change Too little oil Refuel The bolts in the cardan joint gets loose Tighten the bolt

Poor return-abilityThe steering wheel gear wear Adjust or repair the steering wheel gear The steering belt gets loose Adjust the belt Too little hydraulic oil in the reservoir Check the reservoir The power steering gearbreaks down Check the steering device Inappropriate tire charging Charging according to the criterion Inappropriate wheel alignment Check the front wheel alignment The steering column gets stuck Check the steering column

NoiseThe steering gear connection gets loose Tighten the steering gear connection Cardan joint wear Change the cardan joint wear The wheel gear wear Repair the wheel gear

DeviationInappropriate front wheel alignment Adjust the front wheel alignment The rack in the steering gear gets loose Adjust or repair the rack The steering gear connection is twisted or worn Change the steering gear

Steering fluid produce bubblesThere is air in the steering system Discharge the air an check whether it licks There is liquid leakage in the steering system Check the oil cup and refuel There is air in the steering system Discharge the air and check whether it licks No noise elimination function Use the oil pipe with noise elimination function