What causes the rack and pinion system with power steering to leak?

The rack and pinion system with power steering is a common steering mechanism in modern cars, which helps the driver turn the steering wheel more easily through hydraulic power assistance. The core of this system lies in the cooperation between the rack and pinion mechanism and the power steering pump. However, with the use and wear of the vehicle, the rack and pinion system with power steering may have leakage problems, affecting the driving experience and the safety of the vehicle.

This article will discuss in detail the causes of leakage in this system and introduce how to determine whether the rack and pinion system has leakage.

What is the rack and pinion system with power steering?

Before we delve into the leakage problem, it is necessary to understand the basic working principle of the rack and pinion system with power steering. The rack and pinion steering system is a mechanical transmission device, and its basic structure includes gears, racks, power steering pumps and hydraulic lines. When the driver turns the steering wheel, the steering wheel drives the gear to rotate, and the rotational motion of the gear is converted into linear motion through the rack, thereby driving the wheel to turn.

The power steering pump provides power to the rack and pinion through the hydraulic system, making the steering wheel operation easier. In this system, hydraulic oil plays a vital role. The hydraulic oil circulates between the pump and the rack and pinion through the pipeline to provide the necessary pressure for the entire system. However, the leakage of hydraulic oil will weaken or completely lose this power-assisting function, seriously affecting the vehicle's handling performance.

What causes the leakage of the rack and pinion system with power steering?

The leakage of the rack and pinion system with power steering usually stems from multiple factors. Here are some common reasons:

1. Aging and wear of seals

There are multiple seals in the rack and pinion system, such as oil seals and O-rings, which are used to prevent hydraulic oil from leaking out of the system. However, with the passage of time and the use of the vehicle, these seals will gradually age and wear. Rubber materials may become hard, lose elasticity or crack after long-term use, causing hydraulic oil leakage.

2. Damage to the hydraulic pipeline

The hydraulic pipeline is an important channel connecting the power steering pump and the rack and pinion for conveying hydraulic oil. If the hydraulic pipeline is physically damaged, such as scratches, collisions, or excessive bending due to improper installation, it may cause the pipeline to rupture or leak at the joint. In addition, during long-term use, the hydraulic pipeline may also leak due to material fatigue.

3. Wear of the rack and pinion mechanism

The gears and racks in the rack and pinion system are metal parts, which will inevitably wear out during long-term use. When the wear of the gears and racks reaches a certain extent, the fit between the rack and the gear may loosen, causing the hydraulic oil to leak from the joint. Especially without regular maintenance and replacement of the hydraulic oil, the wear will increase and the risk of leakage will increase.

4. Hydraulic oil quality issues

The quality of hydraulic oil is crucial to the normal operation of the rack and pinion system. If unqualified hydraulic oil is used or the hydraulic oil is not replaced for a long time, impurities and sediments in the oil may block the oil circuit or aggravate the wear of the seals, resulting in leakage. In addition, improper hydraulic oil viscosity may also affect the sealing of the system and increase the risk of leakage.

5. External environmental factors

The environment in which the vehicle is traveling may also affect the sealing performance of the rack and pinion system. For example, extreme temperature changes (overheating or overcooling), humid environments, and salt and chemicals on the road can have an adverse effect on the seals and hydraulic pipelines in the system. These external factors may accelerate the aging of seals or corrode hydraulic lines, causing leakage.

6. Improper installation and maintenance

During the installation or maintenance of the rack and pinion system, improper operation, such as improper installation of seals, loose hydraulic line connections, or failure to assemble according to specifications, may cause leakage problems in the system during use. Improper installation and maintenance not only affect the sealing of the system, but may also cause damage to other components.

7. Overload use

The rack and pinion system is designed with the load under normal use in mind, but in actual use, the design load may be exceeded in some cases. For example, under heavy loads, high-speed driving, or frequent sharp turns, the pressure of the system will increase significantly, causing the pressure burden on the seals and hydraulic lines to increase, which in turn causes leakage problems.

How to determine whether the rack and pinion system with power steering is leaking?

Early detection of leakage problems in the rack and pinion system can avoid more serious damage and high repair costs. Here are some common methods to determine whether there is a leak in the rack and pinion system:

1. Check the hydraulic oil level

A drop in the hydraulic oil level is the most direct indication of a rack and pinion system leak. If the hydraulic oil level is below the normal range and the hydraulic oil needs to be added frequently, then there is a high probability that there is a leak in the system. When checking the hydraulic oil level, you should also pay attention to the color and state of the hydraulic oil. Normal hydraulic oil should be clear red or amber. If the hydraulic oil turns black or smells bad, it may mean that there is contamination or severe wear inside the system.

2. Observe the signs of hydraulic oil leakage

Leakage signs are usually the most easily detected leak phenomenon. Check whether there is hydraulic oil seepage under the vehicle or around the power steering system. If there are oil stains under the vehicle, especially the liquid pool formed on the ground after parking, it is very likely that the hydraulic oil of the rack and pinion system is leaking. In addition, you can check the rack and pinion assembly, hydraulic lines and joints for oil or wet marks.

3. Check the steering wheel operation feeling

When the rack and pinion system leaks, the pressure of the hydraulic oil drops, which may cause insufficient steering assistance. The driver will feel that the steering wheel has become heavier, especially when driving at low speed or parking. In addition, the steering wheel may not be smooth during rotation, and there may even be intermittent failures. By driving the vehicle and feeling the steering wheel's operational feedback, you can preliminarily determine whether there is a leak.

4. Listen to the system noise

When the rack-and-pinion system with power steering leaks, the hydraulic oil pressure is insufficient and the power steering pump may make an abnormal noise. This noise usually manifests as a sharp squeak or a low hum, especially when turning the steering wheel. Listening carefully to the changes in the system's sound when the vehicle is stationary and driving can help determine whether there is a leak.

5. Check the wear of the rack-and-pinion components

If you suspect that the rack-and-pinion system is leaking, you can visually inspect the key components of the system, such as gears, racks, seals, and hydraulic lines, to determine if there are signs of wear or damage. Any obvious wear, cracks, or deformation may be a potential cause of the leak and requires further inspection and treatment.

6. Perform a pressure test

The pressure test is a more accurate detection method. A certain amount of hydraulic pressure is applied to the rack-and-pinion system through professional equipment to observe whether the system can maintain a stable pressure. If the system drops pressure or fails to maintain pressure during the pressure test, it indicates a leak. This method usually requires professional technicians to operate, but it can effectively determine the specific location and severity of the leak.

7. Observe the bubble phenomenon of hydraulic oil

The appearance of bubbles in hydraulic oil is also a way to determine the leak. Under normal circumstances, hydraulic oil should be uniform and bubble-free. If bubbles are found in the liquid when checking the hydraulic oil, it may mean that air has entered the system, which is often caused by hydraulic oil leakage or pipeline rupture. The presence of bubbles will affect the transmission efficiency of hydraulic oil and lead to insufficient steering assistance.

8. Check the working status of the power steering pump

The rack and pinion system is closely related to the power steering pump, and leakage problems often affect the normal operation of the pump. By checking the operating status of the power steering pump, such as noise, vibration or overheating, it can assist in determining whether there is a leakage problem in the rack and pinion system. If the working status of the pump is abnormal, the entire power steering system should be checked in time.

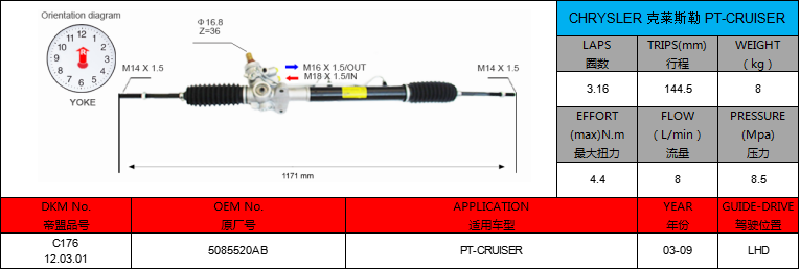

DKM takes pride in its reputation as a leading manufacturer of power steering systems. Our state-of-the-art factory, spanning over 20,000 square meters, produces 300,000 units annually using advanced CNC technology. We cater to global markets, supplying gear rack steering systems for popular brands such as Volkswagen, Hyundai, and Toyota. With competitive factory prices, discounts for bulk purchases, and customizable options, DKM is committed to meeting the diverse needs of our buyers. Contact us today for detailed quotes and take advantage of our wholesale promotions and reliable delivery services.