What role does the rack and pinion play in the steering system?

In the steering system of a car, the rack and pinion are key mechanical components that work together to convert the driver's steering input into actual movement of the wheels. This system not only affects the handling of the vehicle, but is also directly related to driving safety.

This article will explore the role of rack and pinion in the steering system in detail and explain why they are an integral part of modern cars.

What are the basic principles of rack and pinion?

Before understanding the role of rack and pinion, you first need to understand how they work. Rack and pinion systems are a form of mechanical transmission system that is often used to convert rotational motion into linear motion.

Pinion

The pinion is a circular gear mounted on the steering shaft that rotates when the driver turns the steering wheel. This rotational motion drives the rack to move linearly through the meshing of the pinion teeth with the rack teeth.

Rack

The rack is a long strip of teeth on it that meshes tightly with the pinion teeth. When the pinion rotates, the rack moves along its length. This linear motion is transmitted to the wheels through components such as connecting rods, thereby changing the steering angle of the wheels.

What is the role of the rack and pinion in the steering system?

Rack and pinion are the core components of modern car steering systems. They are used in the following ways:

Convert the driver's steering input to the wheel steering

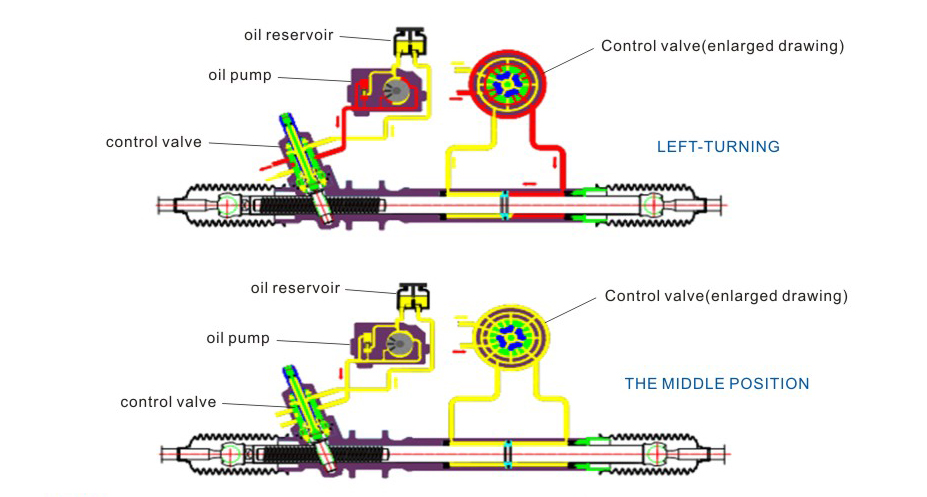

When the driver turns the steering wheel, the rotational motion of the steering wheel is transmitted to the pinion through the steering shaft. The rotation of the pinion drives the rack to move linearly, which pushes the wheel to turn left or right. This process accurately transmits the driver's steering input to the wheel to achieve vehicle steering control.

Provide precise steering control

The design of rack and pinion allows them to provide precise steering control. Because the movement of the rack is strictly proportional to the rotation of the pinion, the driver can accurately control the steering angle of the wheel through the steering wheel. This precision makes the rack and pinion system particularly important at high speeds and during sharp turns, ensuring the stability and handling of the vehicle.

Reduce the complexity of the steering system

Compared to more complex steering system designs, rack and pinion structures are simple and compact. It does not require many additional mechanical parts, thus reducing the complexity and weight of the entire steering system. This feature makes the rack and pinion system particularly suitable for modern passenger cars and light trucks.

Enhanced steering feedback for the driver

Due to the relatively straightforward design of the rack and pinion system, the driver can feel feedback from the road through the steering wheel. This feedback is essential for the driver to judge the road conditions and adjust the driving behavior. For example, when the vehicle is driving on a slippery or uneven road, the driver can sense the changes in the road surface through the subtle vibration of the steering wheel, so as to better control the vehicle.

What are the advantages of the rack and pinion system?

Rack and pinion systems have become a standard configuration in modern cars due to their many advantages. These advantages include:

Simple and efficient

Rack and pinion systems are simple in design, low in manufacturing cost and easy to maintain. They are mechanically efficient and can efficiently transmit the driver's steering force to the wheels, reducing energy loss.

Accurate steering response

Rack and pinion systems can provide direct and accurate steering response, allowing the driver to accurately control the direction of the vehicle through the steering wheel. This accuracy is particularly important for high-speed driving and emergency maneuvers, which can significantly improve driving safety.

Lightweight Design

Rack and pinion systems are compact and lightweight, making them suitable for use in a wide variety of vehicles. This lightweight design not only improves the vehicle's fuel efficiency, but also reduces the vehicle's overall weight, which helps improve the vehicle's handling performance.

What are some common problems with rack and pinion systems?

Despite the many advantages of rack and pinion systems, they can also have some problems, especially under long-term use or harsh conditions. Here are some common problems and their effects:

Wear

The constant friction between the rack and pinion can cause wear, especially when lubrication is insufficient or dust or debris enters the system. Wear can cause the meshing between the rack and pinion to no longer be tight, causing inaccurate steering or loose steering wheels.

Steering sluggishness

Because rack and pinion systems rely on mechanical meshing to achieve steering control, a problem with one of the components can cause steering sluggishness. For example, if the teeth of the rack or pinion are worn or deformed, the driver may find that the steering becomes sluggish or requires more force to turn the steering wheel.

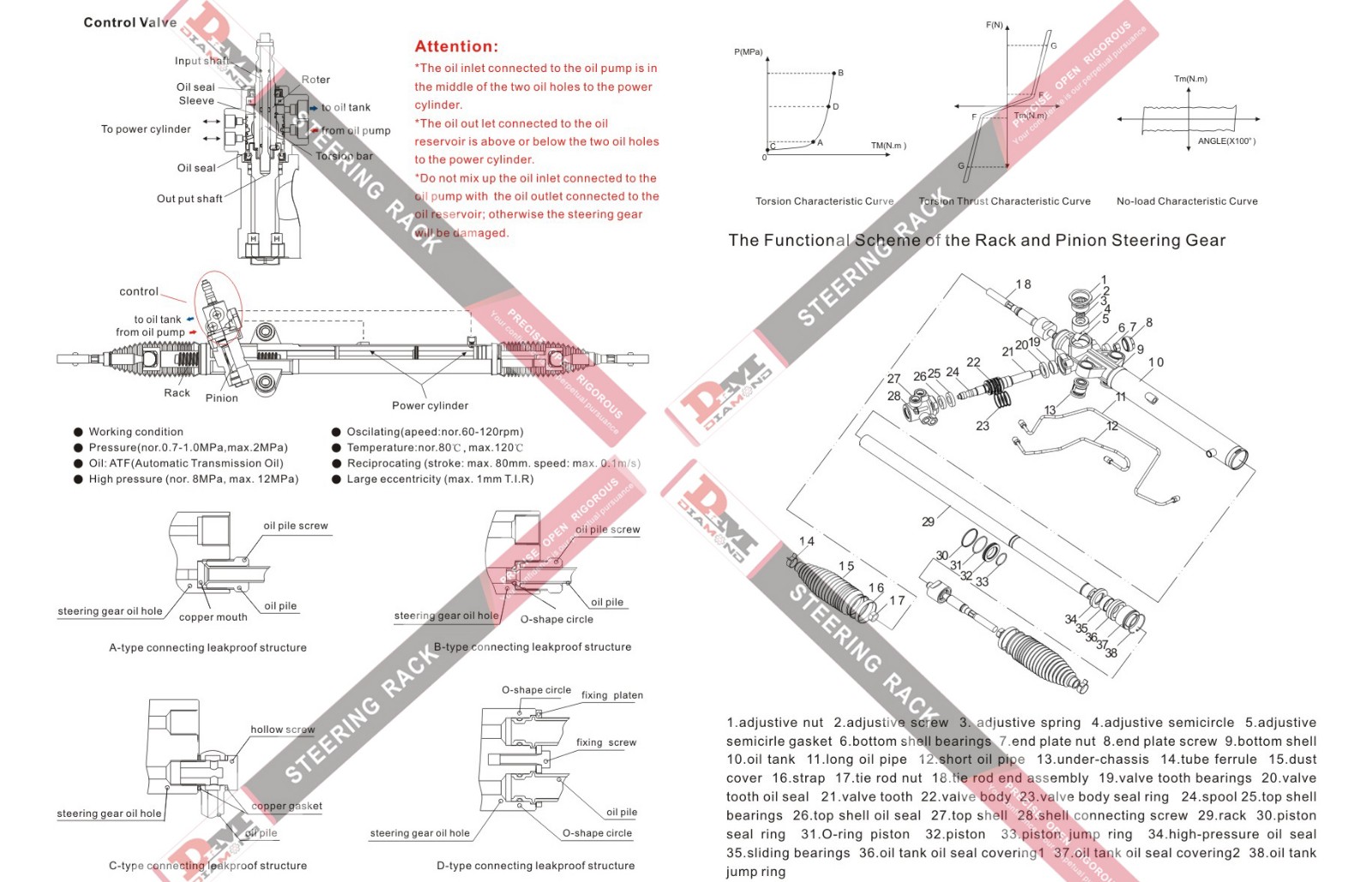

Hydraulic power assist system failure

In some rack and pinion systems, hydraulic power assist systems are used to reduce the driver's steering effort. Once the hydraulic system fails (such as hydraulic oil leakage or hydraulic pump failure), the steering will become abnormally heavy, causing great inconvenience to driving.

How to maintain the rack and pinion system?

The rack and pinion system needs to be checked regularly to detect early signs of wear. Lubrication is also key. Ensuring that there is sufficient lubricating oil or grease between the rack and pinion can effectively reduce wear. In addition, for rack and pinion systems with hydraulic power steering, it is very important to regularly check the level and quality of the hydraulic oil. Make sure that there is no leakage in the hydraulic system and that the hydraulic oil is within the recommended range to maintain the normal operation of the steering power steering.

Once the rack or pinion is found to have signs of damage such as wear and deformation, it should be replaced in time. Otherwise, it may cause more serious steering system problems and even cause driving safety accidents.

Since 1996, DKM has been a trusted name in the automotive parts industry, specializing in power steering systems. Our factory combines advanced automation and precision engineering to produce gear rack steering systems for leading brands like Toyota, Honda, and Hyundai. DKM exports to the USA, Italy, and Russia, offering wholesale deals, competitive prices, and custom manufacturing options. Whether you’re purchasing in bulk or seeking a reliable supplier for long-term cooperation, DKM delivers solutions that meet your requirements. Request a detailed quote today to experience the best in quality and affordability.