What is the most commonly used automotive steering system in the world?

The steering system is one of the most critical components in a car, which is directly related to the vehicle's handling performance and driving safety. From the earliest mechanical steering system to the modern electric power steering system, automotive steering technology has undergone many innovations. Various automotive steering systems are widely used around the world. Different systems have their own advantages and disadvantages, but some steering systems have become the most commonly used systems in the world due to their excellent performance and wide applicability.

This article will explore the most commonly used automotive steering systems in the world today, analyze their working principles, advantages and disadvantages, and the reasons for their wide application.

What is an automotive steering system?

The steering system is an important part of the vehicle's control system. Its main function is to accurately transmit the driver's steering instructions to the wheels to achieve the steering of the vehicle. Whether it is a compact car, SUV, or commercial truck, all vehicles rely on the steering system to maintain the correct driving direction and perform steering operations when necessary.

The performance of the automotive steering system directly affects the vehicle's handling stability, driving comfort and safety. Therefore, designing an efficient and reliable steering system has always been an important topic in the field of automotive engineering.

What are the main types of automotive steering systems?

At present, the common steering system types in the automotive industry mainly include the following:

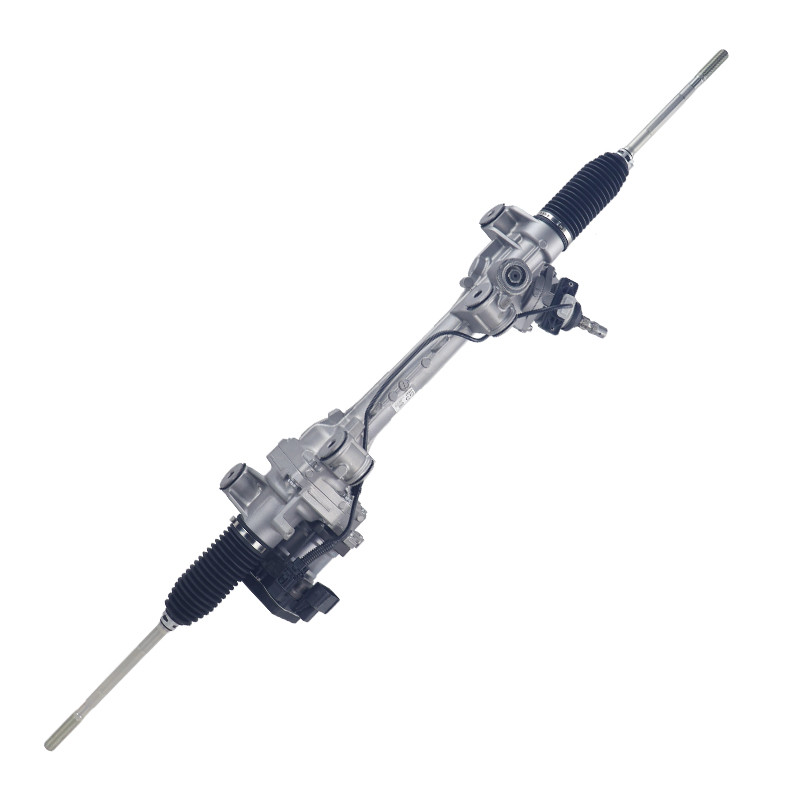

● Mechanical steering system: the earliest type of steering system, a purely mechanical structure, consisting of steering column, steering rack, steering rod and other components.

● Hydraulic power steering system (HPS): provides power through a hydraulic pump to reduce the force required by the driver to turn the steering wheel.

● Electric power steering system (EPS): uses an electric motor to provide power for steering, and has gradually replaced the hydraulic power system and become the mainstream choice.

● Electronic hydraulic power steering system (EHPS): combines the characteristics of hydraulic and electric power steering systems, and optimizes the power steering effect through electronic control.

● Four-wheel steering system (4WS): a system equipped in some high-end models, the front and rear wheels can be steered, which improves handling and stability.

Hydraulic power steering system (HPS)

The working principle of the hydraulic power steering system:

Hydraulic power steering system (HPS) was once the most widely used steering system in the world, especially in the automotive market from the 1990s to the early 21st century. The working principle of the hydraulic power system is to generate pressure through the engine-driven hydraulic pump, and the hydraulic pump delivers high-pressure hydraulic oil to the power cylinder at both ends of the steering rack. When the driver turns the steering wheel, the power valve controls the hydraulic oil to enter the left or right side of the power cylinder according to the rotation direction and amplitude of the steering wheel, thereby providing power assistance and making steering easier.

Advantages of the hydraulic power steering system:

● Real steering force feedback: The force feedback of the hydraulic power system is relatively linear, and the driver can clearly feel the contact between the wheel and the ground, which helps to enhance driving confidence.

● Mature technology and relatively low cost: Since its birth, the hydraulic power steering has undergone decades of development and improvement. Its technology is very mature and its production cost is relatively low.

● Wide range of applications: The hydraulic power system is suitable for various types of vehicles, from small cars to heavy trucks.

Disadvantages of the hydraulic power steering system:

● High energy consumption: The hydraulic power system requires the engine to provide power to drive the hydraulic pump. Even when not steering, the hydraulic pump still works, resulting in energy waste.

● High maintenance cost: The hydraulic power steering needs to replace the hydraulic oil regularly, and the seals are prone to aging and oil leakage, which increases the complexity and cost of maintenance.

● Heavy weight: The hydraulic pump, power cylinder, oil pipe and other components in the hydraulic power system are relatively heavy, which is not conducive to the lightweight design of the vehicle.

Application of hydraulic power steering system:

Hydraulic power steering system was once widely used in various passenger cars and commercial vehicles, especially in the late 20th century, almost all mid-to-high-end vehicles were equipped with hydraulic power steering system. However, with the rise of electric power steering system (EPS), the application of hydraulic power system has gradually decreased, but in some heavy vehicles and special vehicles, hydraulic power steering system still has a place.

Electric power steering system (EPS)

Working principle of electric power steering system:

Electric power steering system (EPS) is one of the most commonly used steering system types in the world. Unlike traditional hydraulic power system, electric power steering system directly provides steering assistance through electric motor. The working principle of the electric power steering system is that when the driver turns the steering wheel, the sensor detects the steering angle and steering force and transmits the signal to the electronic control unit (ECU). The ECU controls the operation of the motor according to the signal, and then provides power to the steering rack through a gear mechanism or a belt drive system.

Advantages of the electric power steering system:

● High energy efficiency: The electric power steering system only starts the motor to provide power when the driver turns, and when driving in a straight line, the motor is in standby mode and does not consume energy. Therefore, the electric power steering system is more energy efficient and can effectively reduce the fuel consumption of the vehicle.

● Light weight: Compared with the hydraulic power steering system, the electric power steering system does not require a hydraulic pump, oil pipe and power cylinder, so it is lighter and helps to achieve the lightweight design of the vehicle.

● Strong programmability: Since the electric power steering system is managed by the electronic control unit, the size and characteristics of the steering assist can be adjusted by software to adapt to different driving conditions and driver preferences.

● Simple maintenance: The electric power steering system does not use hydraulic oil, so there is no need to replace the hydraulic oil, and there is no leakage problem in the hydraulic system, which reduces maintenance costs and complexity.

Disadvantages of Electric Power Steering System:

● Lack of realistic feedback: Although the electric power steering system can simulate a certain force feedback through programming, its force feedback is not as realistic as that of the traditional hydraulic power steering system, which may sometimes make the driver feel a lack of connection with the road.

● Risk of electronic component failure: The electric power steering system relies on the precise operation of electronic components. If the electronic control unit or the motor fails, the steering power may fail.

Application of Electric Power Steering System:

At present, the electric power steering system has become the mainstream configuration in the global automotive market, especially in the field of passenger cars. Almost all newly launched models use electric power steering systems. It is not only used in small cars and SUVs, but also gradually entered the field of some commercial vehicles and heavy vehicles. The widespread application of EPS system is due to its high energy efficiency, lightweight and easy maintenance, and it also meets the increasingly stringent emission and fuel economy standards of modern cars.

Electronic Hydraulic Power Steering System (EHPS)

The working principle of the electronic hydraulic power steering system:

The electronic hydraulic power steering system (Electro-Hydraulic Power Steering, EHPS) is a combination of hydraulic power steering and electric power steering system. Its working principle is to drive the hydraulic pump through an electric motor to provide hydraulic assistance. This system optimizes energy consumption through electronic control while maintaining the advantages of the hydraulic assistance system.

Advantages of electronic hydraulic power steering system:

● Combining the advantages of hydraulic and electric systems: The electronic hydraulic power steering not only retains the good force feedback characteristics of the hydraulic power steering system, but also improves the energy efficiency of the system through the electronic control unit, reducing unnecessary energy consumption.

● Wide applicability: The electronic hydraulic power steering system can be applied to various types of vehicles, especially those large vehicles with high demand for steering assistance, such as trucks and SUVs.

Disadvantages of electronic hydraulic power steering system:

● Complex structure and high cost: The electronic hydraulic power system combines the hydraulic and electric systems, resulting in a more complex structure and relatively high manufacturing and maintenance costs.

● Heavy weight: Compared with the pure electric power steering system, the electronic hydraulic power steering system has a larger overall weight due to the retention of the hydraulic part, which is not conducive to the lightweight design of the vehicle.

Application of electronic hydraulic power steering system:

The electronic hydraulic power steering system is mainly used in vehicles with high demand for steering assistance, such as heavy trucks, SUVs and some high-performance sports cars. These vehicles usually require greater steering assistance, and the electronic hydraulic power steering system can provide strong assistance while maintaining good energy efficiency.

The most commonly used steering system in the world

In general, the electric power steering system (EPS) has become the most commonly used steering system in the world. With its high efficiency, light weight and easy maintenance, this system has gradually replaced the traditional hydraulic power system and become the first choice of major automakers.

Although hydraulic power steering systems and electronic hydraulic power steering systems still have a place in certain specific areas, their application range has gradually narrowed. The advantages of electric power steering systems in energy efficiency, controllability and adaptability have made it widely recognized and used worldwide.

Therefore, the EPS system is undoubtedly the most commonly used steering system in the world, providing a guarantee for the driving safety and comfort of millions of vehicles around the world.