Is replacing the power steering rack a big project?

The power steering rack is an indispensable and important component in modern vehicles, which directly affects the vehicle's handling performance and driving comfort. As one of the core components of the steering system, the replacement of the power steering rack is considered a complex and technically demanding task. For most car owners, replacing the power steering rack may be considered a big project, and this process involves many steps and expertise.

This article will explore the complexity of replacing the power steering rack in detail, analyze the difficulties of each link, and help car owners understand the necessity and challenges of this process.

Basic functions and structure of power steering rack

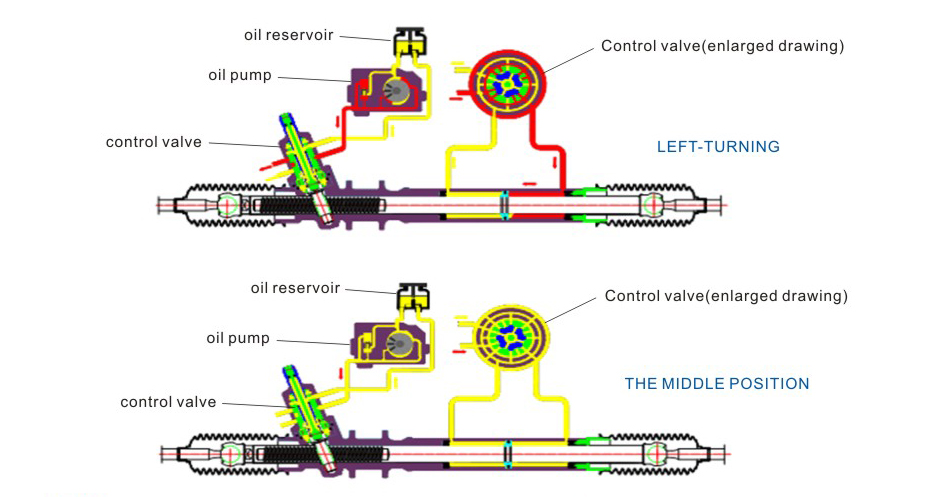

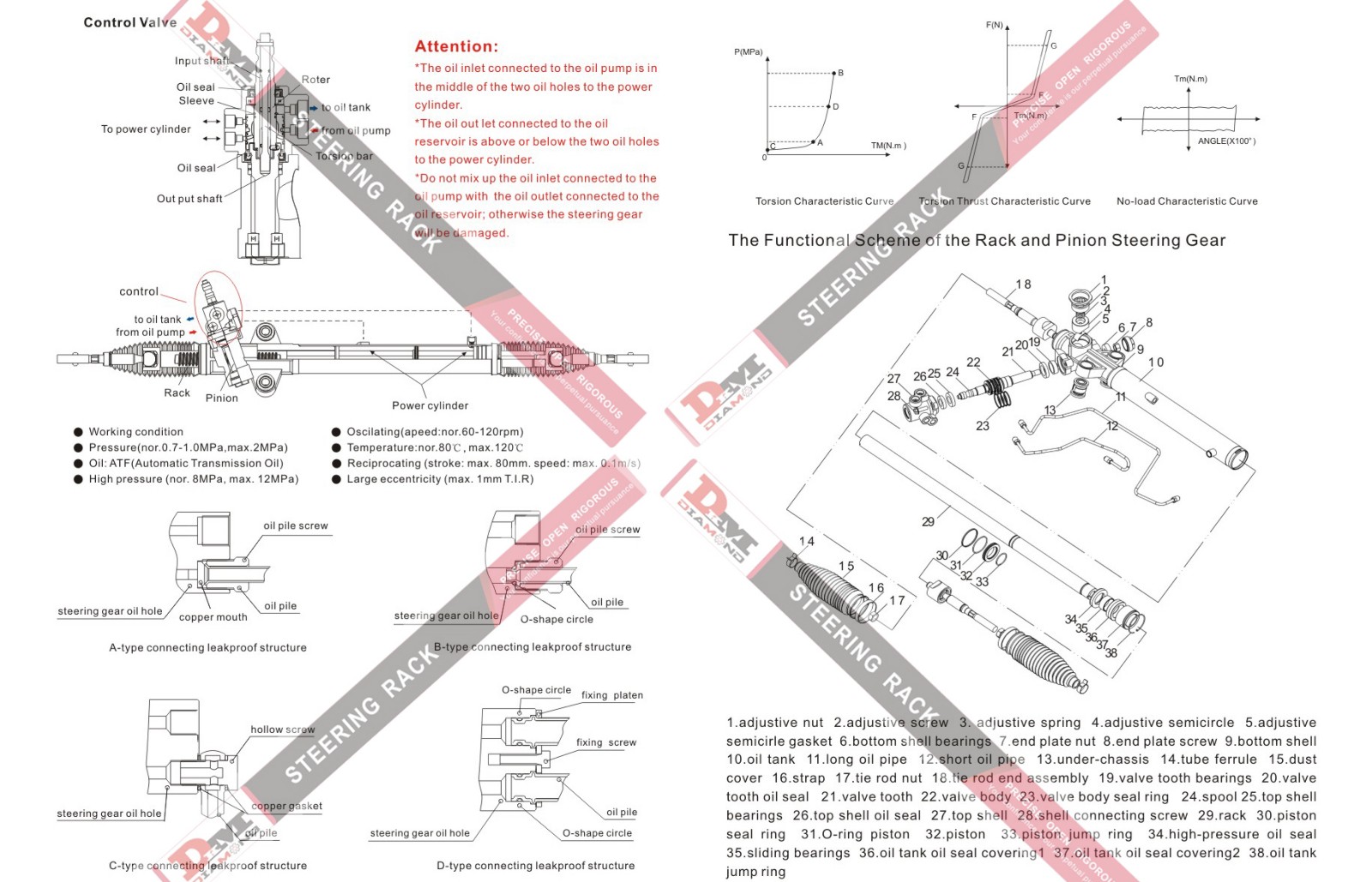

Before discussing the complexity of replacing the power steering rack, it is necessary to understand its functions and structure. The power steering rack is the core component of the steering system, responsible for converting the rotational motion of the steering wheel into the left and right swing of the front wheels of the vehicle, thereby realizing the steering operation. In the traditional rack and pinion steering system, the rack and the gear mesh with each other, and the front wheels are driven to steer through the linear motion of the rack.

The role of the power steering rack is not only steering, but also needs to cooperate with the power steering pump to provide power assistance, so that the driver can control the steering wheel more easily. The hydraulic power steering system provides power assistance under high pressure through hydraulic oil, reducing the force required for steering. This system usually includes components such as pumps, racks, hydraulic lines, and related control valves.

What is the necessity of replacing the power steering rack?

Replacing the power steering rack is usually not a routine maintenance item. It is only necessary to replace it when the rack is severely worn, leaking, or otherwise faulty. When the power steering rack is damaged, serious problems such as heavy steering, poor steering wheel return, and even difficult vehicle control may occur, which not only affects driving comfort but also may pose safety hazards.

In addition, hydraulic oil leakage is also one of the common reasons for replacing the power steering rack. When the seals of the rack are aged or damaged, hydraulic oil may leak, resulting in insufficient pressure in the hydraulic system, which in turn affects steering performance. If the damaged rack is not replaced in time, the problem may worsen and cause the entire steering system to fail.

Is replacing the power steering rack a big project?

Replacing the power steering rack is a technically demanding project involving multiple steps and details, requiring professional equipment and experienced technicians. Here are the main steps and challenges involved in the replacement process:

Removing Steering System Components

The first step in replacing a power steering rack is to remove the steering system components. This includes removing components such as the steering column, steering wheel, steering linkage, and power steering pump. During this process, technicians need to be careful with the various connection points to avoid damaging other components. In addition, the engine or suspension system of some vehicles may affect the removal of the rack, so the vehicle needs to be partially disassembled.

Draining the Hydraulic System

Before removing the power steering rack, the hydraulic fluid in the hydraulic system must be drained. Because the hydraulic fluid is under high pressure in the system, the draining process needs to be carried out carefully to avoid splashing or contaminating the environment. At the same time, the waste hydraulic fluid needs to be handled after draining and disposed of in accordance with environmental regulations.

Removing the Old Rack

Once the hydraulic system has been drained and the necessary components have been removed, the next step is to remove the old rack. The power steering rack is usually installed at the front of the vehicle chassis and is tightly connected to the steering linkage and suspension system. Removing the rack requires loosening multiple bolts and connectors, and may require the use of specialized pulling tools. The rack of some models may be tightly connected to other components, making it more difficult to remove.

Installing a new rack

Before installing a new rack, technicians usually need to check the new part to ensure that its quality and size meet the requirements. The installation process requires the rack to be accurately aligned to the chassis of the vehicle and all the connecting rods and bolts to be reconnected. Any slight deviation in this process may cause the steering system to work poorly, so the accuracy of the installation is crucial.

Reconnecting the hydraulic lines

After installing the new rack, you need to reconnect the hydraulic lines and ensure that all connection points are well sealed. The connection of the hydraulic lines requires not only tightness, but also the direction and length of the lines to ensure that the hydraulic oil can flow smoothly in the system.

Filling and exhausting the hydraulic oil

After completing the installation and connection of all components, the hydraulic oil needs to be refilled and exhausted. Exhausting is to ensure that there is no residual air in the system, which is essential for the normal operation of the hydraulic system. The exhaust process needs to be repeated to exhaust the air from the system by rotating the steering wheel until the hydraulic oil circulates smoothly in the system.

Perform steering system calibration

After replacing the power steering rack, the steering system must be calibrated. The purpose of calibration is to ensure that the center position of the steering wheel is consistent with the straight-ahead position of the front wheels, and the steering wheel rotation angle matches the steering angle of the wheels. This process requires the use of special calibration equipment and can only be completed after multiple tests and adjustments.

Testing and Adjustment

After the replacement is completed, the technician needs to conduct a comprehensive test of the vehicle, including low-speed and high-speed driving, steering stability testing, etc. During the test, if any abnormalities are found, they need to be adjusted immediately. The entire test process is to ensure that the newly installed rack can perfectly cooperate with other parts of the steering system to ensure the steering performance of the vehicle.

How long does it take and how much does it cost to replace the power steering rack?

Given the complexity of replacing the power steering rack, this work usually takes a long time. For a general repair shop or 4S shop, replacing the power steering rack may take several hours or even a day, depending on the model and structural complexity of the vehicle.

In terms of cost, the cost of replacing the power steering rack includes parts and labor costs. The price of the rack itself varies by brand and model, and some high-end vehicles may have more expensive racks. Labor costs depend on the repair shop's charging standards and the difficulty of the replacement process. In some cases, if the replacement process involves the removal or adjustment of other parts, the cost may increase further.

What are the precautions for replacing the power steering rack?

When replacing the power steering rack, it is recommended to choose high-quality parts that match the original accessories. Poor-quality racks may cause frequent steering system failures and affect driving safety. Secondly, since replacing the power steering rack is a complicated task, it is recommended that car owners choose experienced professional maintenance personnel to operate it. Non-professional installation may cause the steering system to malfunction and even bring safety hazards.

In addition, after replacing the power steering rack, the owner should regularly check the working condition of the steering system, including hydraulic oil level, pipe connection, and steering performance. Regular maintenance can extend the service life of the new rack and ensure the reliability of the steering system.

Looking for high-quality, reliable, and affordable power steering rack?

Guangdong Diamond Auto Parts Co., Ltd. is your trusted Chinese manufacturer and supplier. With over 28 years of experience, we specialize in producing gear-and-rack steering systems and hydraulic power components steering for a wide variety of vehicles. Our products serve renowned brands like Toyota, Honda, Hyundai, and Mitsubishi, ensuring compatibility and performance. Our factory, located in Foshan, China, features state-of-the-art CNC equipment and automated production lines, allowing us to produce 300,000 units annually. We provide wholesale deals, bulk discounts, and customized options for large orders.