What type of hydraulic fluid is used in hydraulic power steering systems?

Hydraulic power steering systems are one of the indispensable components in modern cars. It provides drivers with an easier steering experience through the action of hydraulic fluid. However, not all hydraulic fluids are suitable for hydraulic power steering systems. The type and characteristics of hydraulic fluids directly affect the system's operating efficiency, turning performance, and the overall driving experience.

This article will take a deep look at the types of hydraulic fluids used in hydraulic power steering systems and how these fluids affect steering performance.

What is a hydraulic power steering system?

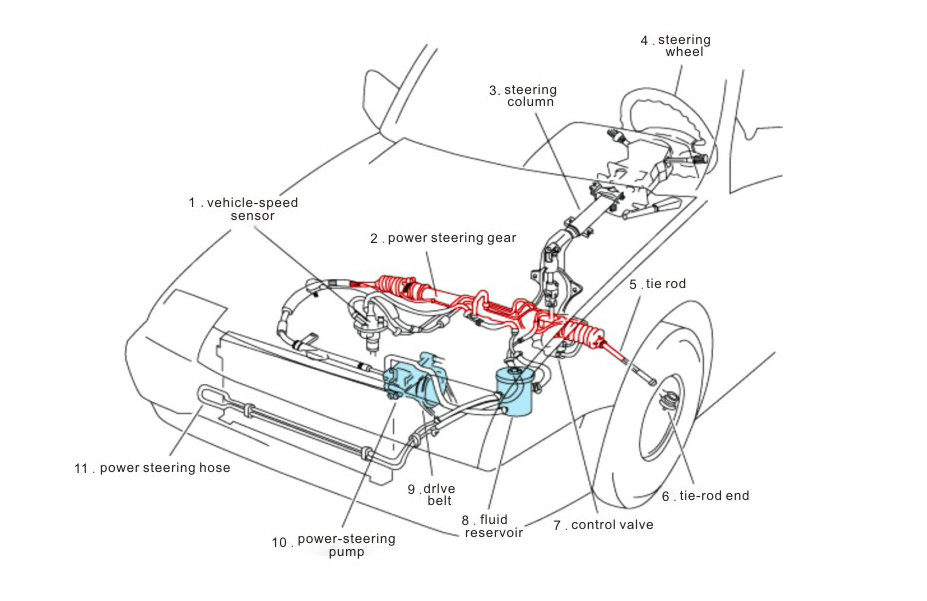

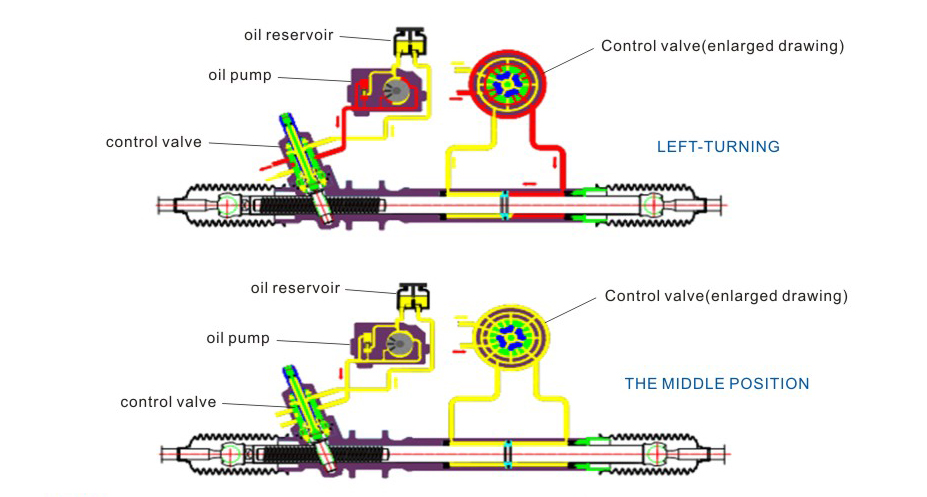

Hydraulic power steering systems (HPS) provide auxiliary power for steering through pressure generated by hydraulic pumps. This system relies on the flow of hydraulic fluid between pipes and components to reduce the amount of force required by the driver to turn the steering wheel. Hydraulic fluid not only acts as a medium for energy transfer in the system, but also plays multiple roles such as lubrication, cooling, and corrosion protection.

What are the types of hydraulic fluids?

The hydraulic fluid used in hydraulic power steering systems must have specific properties to ensure smooth operation and long life of the system. Hydraulic oil is mainly divided into the following types:

1. Mineral Oil

Mineral oil is a liquid extracted from petroleum with good lubricity and anti-corrosion properties. Due to its low cost, it is widely used in various hydraulic systems. However, the viscosity of mineral oil varies greatly with temperature, which may affect the performance of the system under extreme temperature conditions. In addition, mineral oil has poor oxidation stability and is prone to form deposits after long-term use, affecting the operating efficiency of the system.

2. Synthetic Hydraulic Fluid

Synthetic hydraulic fluid is composed of chemically synthesized base oil and additives, and has better temperature resistance and oxidation stability. Synthetic hydraulic fluid can maintain stable viscosity in high and low temperature environments, ensuring that the system can work normally under various working conditions. In addition, synthetic hydraulic fluid also has a longer service life and reduces the frequency of replacement, but its cost is higher.

3. Semi-Synthetic Hydraulic Fluid

Semi-synthetic hydraulic fluid combines the advantages of mineral oil and synthetic oil, has good lubricity and oxidation stability, and is relatively cheap. This fluid strikes a balance between performance and cost and is suitable for the hydraulic power steering systems of most mid-range and high-end vehicles.

4. Specialty Hydraulic Fluids

Some special-purpose hydraulic fluids are specially designed for hydraulic power steering systems under specific conditions. For example, low-temperature hydraulic fluids are suitable for vehicles in cold areas and can maintain good fluidity in low-temperature environments. In addition, some hydraulic fluids are specially designed to resist wear or prevent bubble formation to improve system reliability and service life.

What are the performance characteristics of hydraulic fluids?

The impact of the performance characteristics of hydraulic fluids on hydraulic power steering systems cannot be ignored. The following are the key performance characteristics of hydraulic fluids:

1. Viscosity

Viscosity is one of the most important characteristics of hydraulic fluids, which determines the fluidity and energy transfer efficiency of the fluid in the system. If the viscosity is too high, the fluid will flow slowly, increase the energy consumption and steering resistance of the system; if the viscosity is too low, the fluid may not form enough pressure, affecting the steering assist effect. Therefore, it is crucial to choose a hydraulic fluid with moderate viscosity.

2. Viscosity Index (VI)

Viscosity index is an indicator of the viscosity change of hydraulic oil at different temperatures. The higher the viscosity index, the smaller the viscosity change of hydraulic oil with temperature, which means that the hydraulic oil can maintain stable performance over a wide temperature range. Hydraulic oil with a high viscosity index can ensure the normal operation of the hydraulic system in cold or hot environments.

3. Anti-wear properties

There are many high-speed moving mechanical parts in the hydraulic power steering system. The friction between these parts will cause wear and reduce system efficiency. Hydraulic oil with good anti-wear properties can form a protective film on the surface of the parts, reduce wear and extend the service life of the system.

4. Oxidation stability

Hydraulic oil is prone to oxidation under high temperature and pressure. The generated oxides will form deposits, block the pipes and valves of the hydraulic system, and affect the operating efficiency of the system. Hydraulic oil with good anti-oxidation properties can resist the occurrence of oxidation reactions and keep the system clean and operating normally.

5. Foam Resistance

In the hydraulic system, the formation of foam will increase the compressibility of the oil, affecting the response speed of the system and the stability of the steering assistance. Hydraulic oil with good foam resistance can inhibit the formation of foam, ensuring the fluidity of the oil and the response speed of the system.

Does the type of hydraulic oil affect the turning performance?

Different types of hydraulic oil directly affect the turning performance of the hydraulic power steering system due to their differences in physical and chemical properties.

1. Impact under low temperature conditions

Under low temperature conditions, mineral oil with higher viscosity will become more viscous, causing the fluidity of the hydraulic oil in the system to deteriorate, increasing the turning resistance and making the steering wheel heavy. Synthetic hydraulic oil with a higher viscosity-temperature index can maintain good fluidity at low temperatures to ensure that the steering assistance of the system is not affected.

2. Impact under high temperature conditions

Under high temperature conditions, the viscosity of mineral oil may decrease significantly, resulting in a decrease in the pressure of the hydraulic system and a weakening of the steering assistance effect. Synthetic hydraulic oil, due to its good temperature resistance, can maintain a stable viscosity at high temperatures and provide continuous and stable steering assistance.

3. The impact of anti-wear performance on system life

Hydraulic oil with good anti-wear performance can reduce the wear of internal components of the hydraulic power steering system and extend the service life of the system. Especially when the steering system is frequently used, anti-wear hydraulic oil can effectively protect the system and keep the steering power smooth and efficient.

4. The impact of anti-oxidation performance on system cleanliness

The anti-oxidation performance of hydraulic oil directly affects the cleanliness of the system. The deposits produced by oxidation may block the pipes of the system, affecting the flow of oil and the overall performance of the system. Hydraulic oil with good anti-oxidation performance can reduce the formation of deposits, keep the system clean, and ensure that the oil flows smoothly in the system.

5. The impact of anti-foaming performance on turning smoothness

The foam in the hydraulic oil will increase the compressibility of the oil in the hydraulic system, making the system response slower and the steering power unstable. Hydraulic oil with good anti-foaming performance can keep the system running smoothly and ensure that the driver can get continuous and stable power when turning the steering wheel.

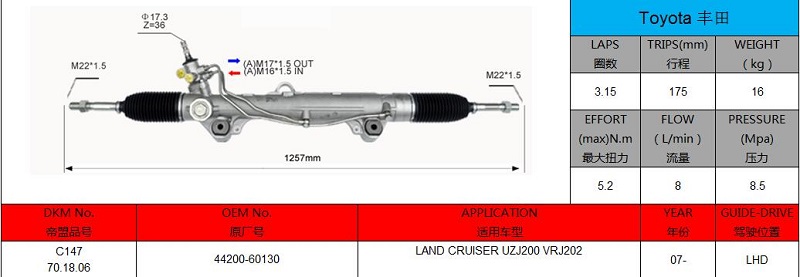

Guangdong Diamond Auto Parts Co., Ltd., known as DKM Company, is a professional manufacturer of power steering systems that meet the demands of international markets. Established in 1996, we have grown to become a leading supplier of gear-and-rack steering systems and hydraulic steering solutions. Our products are trusted by OEMs, distributors, and dealers in the USA, Europe, Russia, and Southeast Asia. With a factory spanning 20,000 square meters and equipped with 280+ CNC machines, we maintain a production capacity of 300,000 units per year. Contact us today for a detailed quote or to learn more about our promotional offers!