Why are cars switching to electric power steering racks?

Over the past few decades, the automotive industry has undergone many major changes, one of which is the evolution of steering systems. Traditional hydraulic power steering systems used to be standard on the vast majority of cars. However, as technology develops and demand changes, more and more automakers are adopting electric power steering racks and gradually abandoning traditional hydraulic systems.

This trend is not accidental, but is driven by a variety of factors. This article will explore in detail why the automotive industry is switching to electric power steering racks and abandoning traditional hydraulic steering systems.

What are the limitations of traditional hydraulic power steering systems?

1. Complex mechanical structure and high maintenance cost

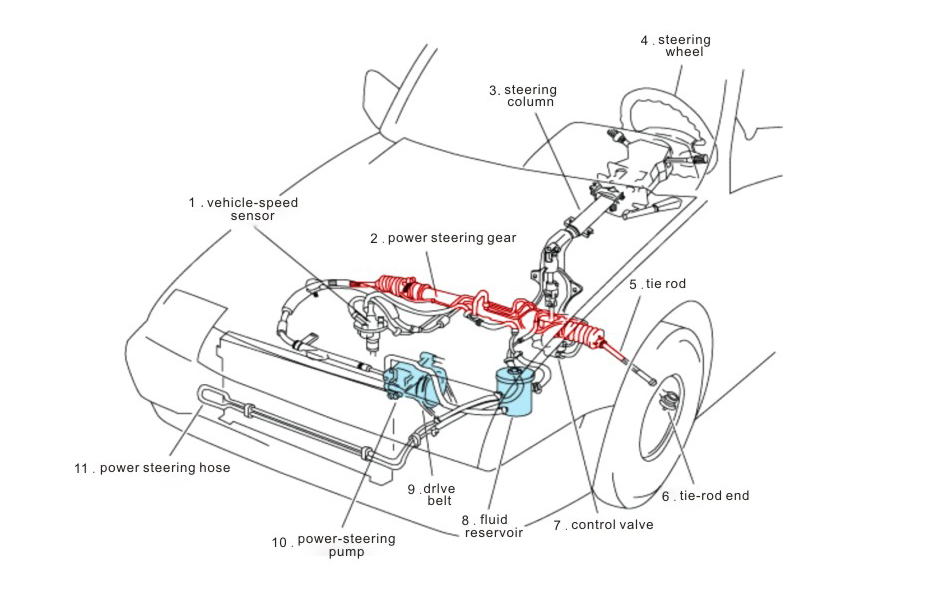

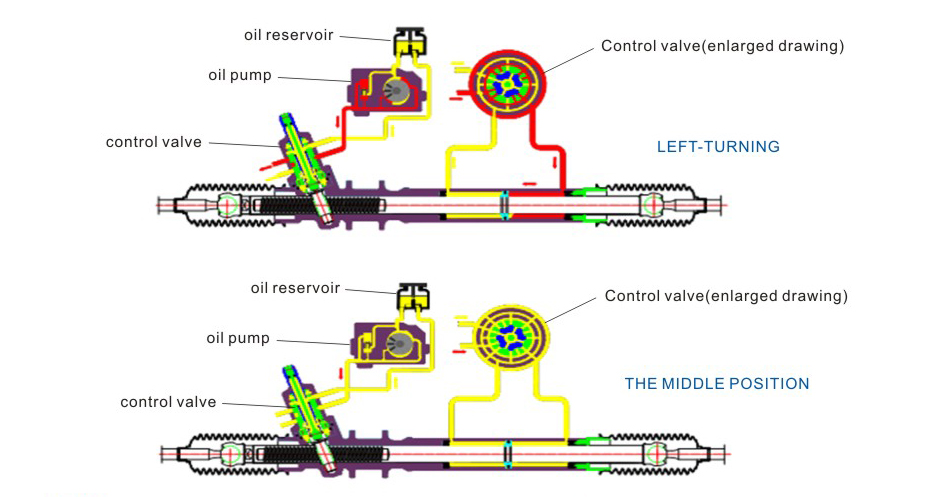

Traditional hydraulic power steering systems rely on multiple mechanical components such as hydraulic pumps, hydraulic cylinders, steering valves, oil pipes and oil storage tanks. The hydraulic pump is usually driven by the engine through a belt and consumes the power of the engine to operate. The hydraulic oil circulates in the system and pushes the hydraulic cylinder through pressure, making steering easier. However, the complexity of this system brings a series of problems.

● High maintenance requirements: The hydraulic oil in the hydraulic system needs to be replaced regularly, and the seals and pipes are also prone to aging and damage, resulting in hydraulic oil leakage. Once a leak occurs, it will not only affect steering performance, but may also cause environmental pollution. Repairing these problems usually requires high labor costs and parts costs.

● Low energy efficiency: Because the hydraulic pump is directly driven by the engine, the hydraulic steering system is always running, even when the vehicle is driving in a straight line. This means that the hydraulic steering system consumes additional fuel, which reduces overall energy efficiency.

2. Limited design flexibility

The design of the hydraulic power steering system is relatively fixed and difficult to adapt to different models and driving needs. The layout of the hydraulic system is limited by the space requirements of the engine compartment and the layout of the hydraulic pipeline, which makes the designer less flexible when designing the steering system. In addition, the power-assisting effect of the hydraulic system is difficult to control accurately, and it is difficult to provide the best steering power according to different driving conditions (such as high-speed driving or low-speed parking).

3. Unstable steering feel

The hydraulic power steering system needs to find a balance between the power-assisting effect and the steering feel in design. In order to provide sufficient power, the hydraulic system often sacrifices some of the clarity of the steering feel. This may cause the driver to feel that the steering is too light or not linear enough in some cases, affecting the driving experience.

What are the advantages of electric power steering racks?

1. Improved energy efficiency

A significant advantage of the electric power steering rack is its higher energy efficiency. Unlike hydraulic systems, the electric power steering system only activates the electric motor to provide assistance when steering assistance is needed. The electric power steering system does not consume electricity when the vehicle is driving in a straight line or when steering is not required. This on-demand power-assist design greatly reduces unnecessary energy consumption and improves overall fuel economy.

2. Design flexibility and modularity

The electric power steering rack uses electronic control technology, which gives it higher design flexibility. The electric power steering system no longer relies on the layout of the engine, so it can be arranged more freely in any position of the vehicle to meet the needs of different models. This modular design makes it easier for manufacturers to use the same steering system on different models, reducing production costs.

In addition, the electronic control system can adjust the power assistance effect according to different driving conditions. For example, at low speeds, the system can provide stronger power assistance to facilitate parking and slow-speed turns; while at high speeds, the system can reduce power assistance to enhance the driver's sense of control over the vehicle. Such intelligent adjustment functions enable the electric power steering system to better adapt to various driving scenarios and provide more accurate steering feedback.

3. Reliability and low maintenance requirements

Compared to hydraulic systems, electric power steering racks have fewer mechanical parts, reducing the possibility of wear and failure. Since hydraulic pumps, hydraulic oil and related seals are not required, electric power steering racks avoid hydraulic oil leakage and related maintenance issues. Although electric power steering systems rely on electronic components, advances in modern electronic technology have greatly improved the reliability of these components, reducing failure rates and maintenance requirements.

4. Precise steering control

The electric power steering rack monitors the steering wheel rotation angle and speed in real time through sensors and electronic control units (ECUs) to provide precise steering assistance. This allows the driver to better perceive road conditions and improve driving safety and comfort. In addition, the electric power steering system can also be seamlessly integrated with other electronic control systems of the vehicle (such as the body stability control system) to achieve more intelligent driving assistance functions.

Wide application of electric power steering racks

As the advantages of electric power steering racks are gradually recognized, more and more automakers are beginning to adopt electric power steering systems in their models. This includes not only small cars and sedans, but also a variety of models such as SUVs, trucks and luxury cars. Whether it is daily driving or intense control, the electric power steering system can provide corresponding steering assistance to meet the needs of different consumers.

Secondly, the electronic characteristics of the electric power steering rack make it an important part of autonomous driving technology. In autonomous vehicles, the vehicle needs to be able to steer autonomously, and the electric power steering system controls the steering assistance through electronic signals, which can achieve precise automatic steering control. This is one of the reasons why the electric power steering system will play an important role in future autonomous vehicles.

Why is the traditional hydraulic steering system gradually eliminated?

1. Natural elimination brought about by technological development

With the continuous development of electronic technology, the manufacturing cost of the electric power steering rack has gradually decreased, while its performance and reliability have been continuously improved. This technological advancement has enabled the electric power steering system to gradually replace the traditional hydraulic system. Although the hydraulic steering system has dominated the past few decades, the development of technology has eventually led to its gradual withdrawal from the stage of history.

2. Changes in market demand

Modern consumers have increasingly diverse requirements for cars, not only focusing on the performance of the vehicle, but also on its fuel economy, environmental protection and intelligence. The electric power steering rack can better meet these needs, while the traditional hydraulic steering system seems to be unable to do so in these aspects. The change in market demand has directly driven the widespread adoption of electric power steering systems by automakers.

3. Cost-effectiveness considerations

Although the initial R&D cost of electric power steering racks is high, their long-term use costs are relatively low. Traditional hydraulic steering systems have high maintenance costs, especially when hydraulic oil and seals need to be replaced frequently. Electric power steering racks, due to their low maintenance requirements and higher energy efficiency, can save more costs for car owners and manufacturers in the long run. This cost-effectiveness consideration is also one of the important reasons why automakers choose electric power steering systems.

As a professional power steering system manufacturer, Guangdong Diamond Auto Parts Co., Ltd. (DKM Company) delivers premium products tailored for global automotive brands. Founded in 1996, we serve clients across North America, Europe, Southeast Asia, and other regions. Our state-of-the-art factory, spanning 20,000 square meters, is outfitted with 280+ CNC machines and advanced assembly lines, ensuring consistent quality and reliable supply. We produce high-precision gear-and-rack steering systems, hydraulic steering systems, and other components compatible with Toyota, Honda, Volkswagen, Hyundai, Mitsubishi, and more. By leveraging world-class technology and focusing on affordability, we offer unmatched value for bulk buyers and distributors. Explore our promotional discounts, low prices, and wholesale opportunities by contacting us for a detailed quote today!