Are cars still using hydraulic power steering racks?

In the long history of the automotive industry, the steering system has undergone many technological innovations. From the early manual steering rack to today's hydraulic and electronic steering systems, the development of steering technology has not only improved driving comfort, but also greatly improved the handling and safety of vehicles. Hydraulic power steering racks used to be the standard configuration of automotive steering systems, but with the development of technology, other types of steering systems have gradually emerged.

So, are today's cars still using hydraulic power steering racks? Among the existing steering racks, which type is the best?

What are the principles and advantages of hydraulic power steering racks?

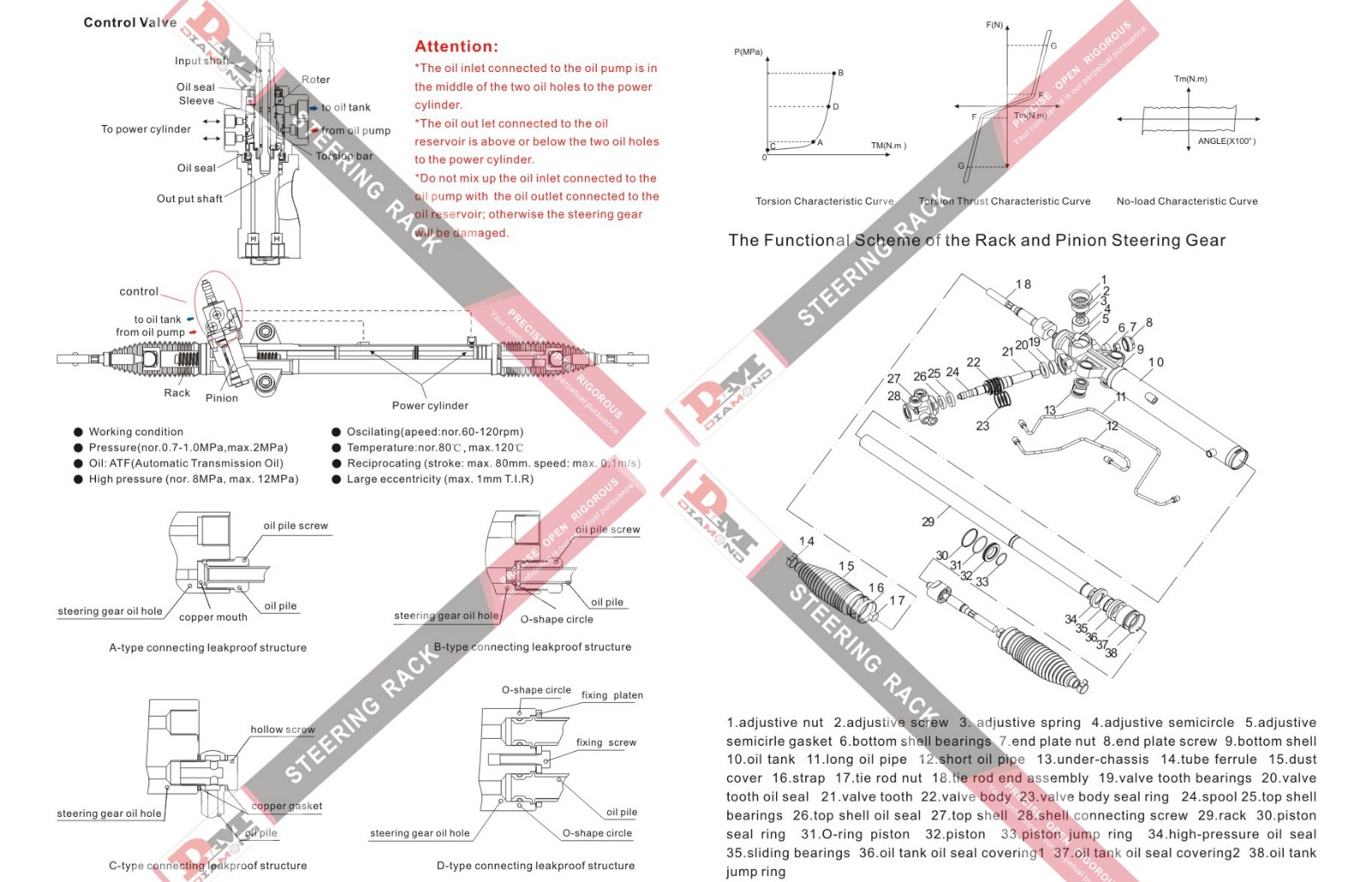

A hydraulic power steering rack is a steering system that relies on a hydraulic system to provide power assistance. Its core components include a steering rack, a hydraulic pump, a hydraulic cylinder, and related hydraulic lines. When the driver turns the steering wheel, the hydraulic pump delivers hydraulic oil to the hydraulic cylinder, which pushes the rack to move through hydraulic pressure, and ultimately drives the wheels to turn. The main advantages of hydraulic power steering rack are:

1. Powerful steering assistance: The hydraulic system provides significant steering assistance, especially when driving at low speed or parking, the hydraulic assistance can effectively reduce the driver's operating burden.

2. Sensitive operation: The hydraulic power steering rack responds quickly, can quickly adjust the power assistance, and provides a sensitive control experience.

3. Low cost: The manufacturing and maintenance costs of hydraulic power steering racks are relatively low, and they have been widely used in various models, especially in mid- and low-end models and light trucks.

Are cars still using hydraulic power steering racks?

Although hydraulic power steering racks were once the mainstream choice for automotive steering systems, with the advancement of electronic technology, other types of steering systems have gradually occupied an important position in the market. However, this does not mean that hydraulic power steering racks have been completely eliminated. In fact, hydraulic steering systems are still widely used in many models, especially in some vehicles that are cost-sensitive and have high requirements for driving experience.

The current situation of using hydraulic power steering racks:

1. Mid- and low-end models: Hydraulic steering systems are still standard configurations for many mid- and low-end models. Due to its lower cost and reliable performance, these models usually choose hydraulic power steering rack to balance cost and handling performance.

2. Commercial vehicles and trucks: In some light trucks and commercial vehicles, hydraulic steering systems are still widely used due to their powerful power-assisting effect and reliability. These vehicles often need to turn frequently at low speeds, so the advantages of hydraulic power steering racks are obvious.

3. Specific driving scenarios: Hydraulic power steering racks still have irreplaceable advantages in some special driving scenarios. For example, in off-road vehicles or heavy off-road trucks, hydraulic steering systems can provide stable and powerful power assistance, helping drivers to easily turn in complex road conditions.

Despite this, the share of hydraulic power steering racks in the passenger car market is gradually decreasing because the Electric Power Steering (EPS) system performs better in many aspects.

Hydraulic power steering rack vs. other types of steering racks: What is the difference?

At present, there are three main types of common automotive steering systems on the market: Hydraulic Power Steering (HPS), Electric Power Steering (EPS) and Electro-Hydraulic Power Steering (EHPS). Each system has its own unique advantages and applicable scenarios. Next, we will compare these three systems in detail.

Hydraulic Power Steering Rack

Advantages:

● Powerful steering assistance: Especially at low speeds, the hydraulic power steering rack can provide greater assistance, making parking and low-speed steering easier.

● Sensitive operation: The hydraulic system can adjust the power assistance in real time according to the driver's operation, providing a more direct control experience.

Disadvantages:

● High energy consumption: The hydraulic pump is directly driven by the engine, continuously consuming engine power and affecting fuel efficiency.

● Increased weight: The pipes and cylinders of the hydraulic system increase the weight of the vehicle body, which has an adverse effect on the fuel economy of the vehicle.

● High maintenance requirements: The pipes, pumps, valves and other components in the hydraulic power steering rack are prone to wear and may require regular maintenance and replacement.

Electronic Steering Rack

Advantages:

● Energy saving: The electronic steering system provides power assistance through the motor and does not rely on engine power, so it consumes almost no energy when the vehicle is not steering.

● Light weight: The electronic steering system does not require hydraulic oil pipes and pumps, and the overall weight is lighter, which helps to improve the fuel economy of the vehicle.

● Strong adjustability: The electronic steering system can automatically adjust the power assistance according to the vehicle speed, road conditions and driving mode, providing a more flexible control experience.

Disadvantages:

● High cost: The manufacturing and maintenance costs of the electronic steering system are higher than those of the hydraulic system.

● Weak road feel: Compared with the hydraulic system, the electronic system has weaker transmission of road feedback, which may affect the driver's perception of the road.

Electro-hydraulic hybrid steering rack (EHPS)

Advantages:

● Combining the advantages of both: The electro-hydraulic hybrid steering system combines the powerful power assistance of the hydraulic system and the energy-saving advantages of the electronic system, providing hydraulic power assistance at low speeds and relying mainly on the electronic system at high speeds.

● Energy consumption optimization: The EHPS system optimizes the work of the hydraulic pump through electronic control, reducing unnecessary energy consumption.

Disadvantages:

● Increased complexity: The complexity of the hybrid system increases the possibility of failure and also increases the difficulty of maintenance.

● Higher cost: Due to the integration of the characteristics of both hydraulic and electronic systems, the manufacturing and maintenance costs of EHPS are relatively high.

Which type of steering rack is best?

There is no unified answer to the question of "which type of steering rack is best". Different types of steering systems have their own advantages and disadvantages and are suitable for different usage scenarios and driving needs.

● For ordinary passenger cars: If you pay more attention to fuel economy and comfortable driving experience, the electronic power steering system (EPS) may be the best choice. It is not only energy-saving and environmentally friendly, but also can adjust the power according to the driving mode, providing a more intelligent control experience.

● For heavy vehicles or off-road vehicles: If you need more powerful steering power, especially at low speeds, hydraulic power steering rack is still an irreplaceable choice. Its reliability and powerful power effect are excellent in special driving environments.

● For the need to balance energy saving and control: the electro-hydraulic hybrid steering system (EHPS) provides a solution that has the best of both worlds. It provides an ideal balance of adequate hydraulic assistance at low speeds while optimizing energy consumption through electronics at high speeds.

Looking for a reliable supplier of power steering systems? Guangdong Diamond Auto Parts Co., Ltd. (DKM Company) is your trusted partner for high-quality auto parts manufacturing. Established in 1996, we have over two decades of experience producing durable and affordable steering systems for passenger cars, SUVs, and commercial vehicles. Our factory integrates advanced CNC machining and automated production lines, enabling us to manufacture 300,000 units annually for clients in the USA, Italy, Russia, and Southeast Asia. We cater to a wide range of automotive brands, including Toyota, Honda, Mitsubishi, Hyundai, and Volkswagen. Whether you need standard products, custom solutions, or large-volume discounts, we have you covered. Contact us today to take advantage of our low prices, wholesale deals, and exclusive promotions!